Home > Nickel Alloy > Nickel Alloy Instrumentation Tubing

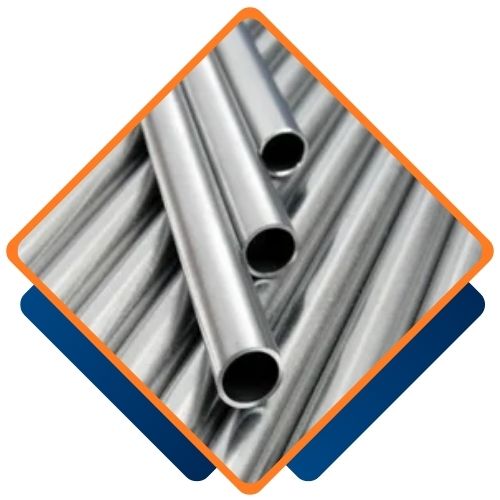

Bosega Pipes and Tubes, located in Cape Town, South Africa, specializes in providing top-notch **Nickel Alloy Instrumentation Tubing** tailored for precision control systems that operate in the harshest environments. These tubes are crafted to offer exceptional corrosion resistance, pressure integrity, and performance even in high-temperature or chemically aggressive settings. Manufactured to meet rigorous international standards, Bosega’s nickel alloy tubing is essential for critical applications in various industries, including oil and gas, petrochemical, power generation, and marine engineering.

Nickel alloy instrumentation tubing typically consists of high nickel content (around 50-70%), with elements like chromium, molybdenum, and iron to enhance corrosion resistance and strength. Mechanical properties include high tensile strength (up to 1,200 MPa), excellent ductility, and resistance to stress corrosion cracking. The advantages of nickel alloy instrumentation tubing include superior corrosion resistance in harsh environments, high-temperature stability, lightweight nature, and excellent weldability. These properties make it ideal for chemical processing, oil and gas, and aerospace applications where reliability is critical.

| Nickel Alloy Specification | ASTM B163/ ASME SB163, ASTM B725/ ASME SB725 |

| Nickel Alloy Grades | UNSN08811, UNSN08825, UNSN08020, UNSN10276 |

| Nickel Alloy Type | SEAMLESS / WELDED / ERW / EFW / COLD DRAW / HOT FINISH / COLD FINISH |

| Nickel Alloy Outer Diameter Size | SEAMLESS – 1/2″ NB TO 18″ NB WELDED / ERW- 1″ NB TO 16″ NB EFW – 8″ NB TO 110″ NB |

| Nickel Alloy Wall Thickness | Schedule 10 To Schedule 160 (3 mm to 100 mm Thickness) |

| Nickel Alloy Length | 01 Meter to 12.5 Meters, Single Random Length, Double Random Length And Customize Size. |

| Nickel Alloy Ends | Plain Ends / Beveled Ends |

| Nickel Alloy Delivery Conditions | As Rolled, Formed, Stress Relieved, Annealed, Hardened, Tempered, Cold Draw, Bright Annealed |

| Nickel Alloy Coating | Electropolish, Mechanical Polish, Satin Finish, Passivated |

| Nickel Alloy Other Testing | Product Analysis, Transverse Tension Test, Flattening Test, Etching Test, Radiographic Examination, Stabilizing Heat Treatment, Intergranular Corrosion Test, Weld Decay Test, Magnetic Particle Detection, Grain Size Test, NACE 0175, Dual Grade, PWHT (POST WELD HEAT TREATMENT), Flare Test, Bend Test, Hardness Test, Tensile Test etc |

| Nickel Alloy Dimension | All Pipes Is Manufactured and Inspected / Tested to the Relevant standards including ASTM and ASME |

| Nickel Alloy Value Added Services | Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

| Nickel Alloy Packaging | Loose / Bundle / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector |

| Nickel Alloy Shipment & Transportation | By Road – Truck / Train, By Sea – Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air – Freighter Civil Passenger and Cargo Planes |

| Nickel Alloy Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |

| Ni % | Cu % | Fe% | Mn % | C % | Si % | S % |

| 63.0 min | 28.0-34.0 | 2.50 max | 2.00 max | 0.30 max | 0.50 max | 0.024 max |

| Tensile Strength, Mpa | Yield Strength, MPa | Elongation, % | Hardness, HRB | |

| 483 min | 193 min | 35 min | – | +A |

| 586 min | 379 min | 15 min | 75 max | SR |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Our nickel alloy tubing comes in a variety of grades such as **Alloy 200/201**, **Alloy 400**, **Alloy 600**, **Alloy 625**, and **Alloy 825**. Each grade is designed to provide unique resistance to corrosion, oxidation, and thermal degradation. These alloys excel in resisting acids, alkalis, seawater, and high-pressure steam, making them perfect for demanding instrumentation systems. With smooth internal surfaces, tight tolerances, and impressive strength-to-weight ratios, our tubing ensures reliable signal and fluid transmission in high-performance control systems.

Bosega Pipes and Tubes, one of the largest suppliers of Nickel Alloy Instrumentation Tubing in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Our extensive inventory and commitment to exceptional service make us the go-to choice for nickel alloy products in the region.

Common applications for this tubing include **process control lines**, **pressure and temperature instrumentation**, **chemical injection systems**, and **hydraulic and pneumatic control systems** found in offshore platforms, refineries, chemical plants, and nuclear facilities. This tubing is specifically selected for its ability to maintain structural integrity and precise performance in environments where standard stainless steel would corrode or fail. Bosega’s Nickel Alloy Instrumentation Tubing guarantees long-term reliability and accuracy in critical operations, where safety and system performance are paramount.

Nickel alloy instrumentation tubing is widely used in various industries due to its excellent corrosion resistance and high-temperature stability. It is commonly employed in oil and gas, chemical processing, and power generation sectors for pressure measurement, fluid transfer, and process control applications. The tubing’s durability and resistance to stress corrosion cracking make it ideal for harsh environments. Additionally, it is utilized in aerospace and marine applications, where lightweight yet strong materials are essential for ensuring reliable performance and safety in demanding conditions.

©2024 Bosega Pipes and Tubes . All Rights Reserved.