Home > Nickel Alloy > Nickel Alloy 201 Tubing

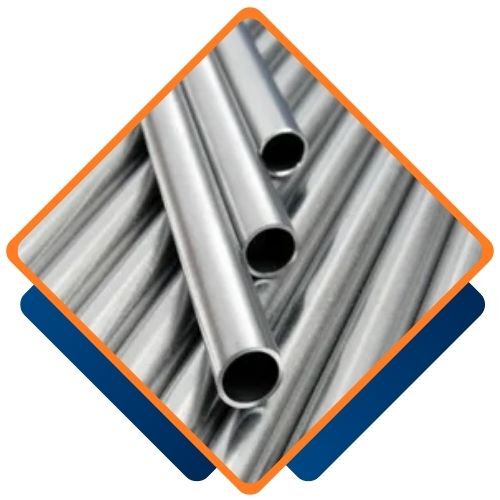

Bosega Pipes and Tubes, located in Cape Town, South Africa, stands out as a top manufacturer and supplier of high-quality Nickel Alloy 201 Tubing. This tubing is celebrated for its remarkable corrosion resistance, impressive strength, and thermal stability, making it perfect for the rigorous demands of industrial and chemical applications. At Bosega, they utilize cutting-edge manufacturing techniques and maintain strict quality control to guarantee precise dimensions, smooth finishes, and durability that lasts. Nickel Alloy 201 tubing is a go-to choice in industries like chemical processing, petrochemical, aerospace, and power generation, thanks to its exceptional ability to withstand reducing environments, oxidation, and high temperatures. This makes it ideal for critical piping, heat exchangers, and high-performance systems.

The composition of Nickel Alloy 201 Tubing is primarily over 99% nickel, with only trace amounts of carbon, iron, and copper, which contributes to its outstanding corrosion and chemical resistance. It boasts a tensile strength of about 550–700 MPa, a yield strength of around 200–300 MPa, and an elongation rate of 30–40%. This tubing is known for its superior toughness, resistance to creep, and stability at high temperatures. Its mechanical and chemical properties make it a reliable choice for environments that demand resistance to reducing acids, thermal cycling, and high-pressure conditions, ensuring it remains durable and dependable in critical industrial settings.

Tube Size : 15 NB to 150 NB IN

Tube Type : Seamless / ERW / Welded / Fabricated / Hollow / LSAW Pipes

tubing wall thickness: .035″ –.095′, (special wall thicknesses available)

tube Schedule : SCH5, SCH10, SCH40, STD, SCH80, SCH160

Tube Finish : Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF

tube Form : Round, Square, Rectangular, Hydraulic, Straight or ‘U’ bent Tubes Etc.

tube Length : Single Random, Double Random & Cut Length.

End : Plain End, Beveled End, Treaded

Marking: All Nickel 201 tubes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.)

We can also cut, thread, and groove Nickel 201 Tubes to meet your specifications.

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Nickel 201 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min | – |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Nickel 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel 201 | 2.4068 | N02201 | NW 2201 | NA 12 | НП-2 | – | LC-Ni 99 |

Choosing Nickel Alloy 201 Tubing from Bosega Pipes and Tubes ensures high quality and durability, as these tubing offer excellent corrosion resistance and strength. Our commitment to exceptional service and reliable delivery guarantees customer satisfaction across various industrial applications. Our expertise in nickel alloy products ensures you receive a top-tier solution tailored to your needs.

Bosega Pipes and Tubes, one of the largest suppliers of Nickel Alloy 201 Tubing in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for nickel alloy products in the region.

| Wall | Sizes ( O.D.) |

|---|---|

| .010 | 1/16″ , 1/8″ , 3/16″ |

| .020 | 1/16″ , 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ |

| .012 | 1/8″ |

| .016 | 1/8″ , 3/16″ |

| .028 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 3/4″ , 1″ , 1 1/2″ , 2″ |

| .035 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 7/16″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .049 | 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/8″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .065 | 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 3/4″ , 2″ , 2 1/2″ , 3″ |

| .083 | 1/4″ , 3/8″ , 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 7/8″ , 2″ , 2 1/2″ ,3″ |

| .095 | 1/2″ , 5/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .109 | 1/2″ , 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .120 | 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 2 1/4″ , 2 1/2″ , 3″ |

| .125 | 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 3″ , 3 1/4″ |

| .134 | 1″ |

| .250 | 3″ |

| .375 | 3 1/2″ |

Yes, we offer custom sizes for Nickel Alloy 201 Tubing to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

Nickel Alloy 201 Tubing is a go-to choice for a variety of applications that demand corrosion resistance, high strength, and the ability to withstand high temperatures. You’ll often find it in chemical reactors, heat exchangers, petrochemical processing systems, aerospace components, and power generation equipment. Thanks to its seamless design, it maintains structural integrity and promotes efficient fluid flow while keeping contamination to a minimum. Plus, its excellent weldability and formability make it easy to fabricate into complex systems. With remarkable resistance to reducing acids, oxidation, and thermal stress, Nickel Alloy 201 tubing ensures safe, reliable, and long-lasting performance in critical industrial, chemical, and high-temperature settings, all while delivering efficiency and durability even in the toughest conditions.

©2024 Bosega Pipes and Tubes . All Rights Reserved.