Home > Stainless Steel >Stainless Steel 317 and 317L EFW Pipes

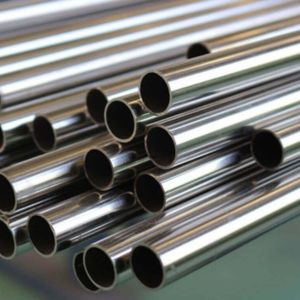

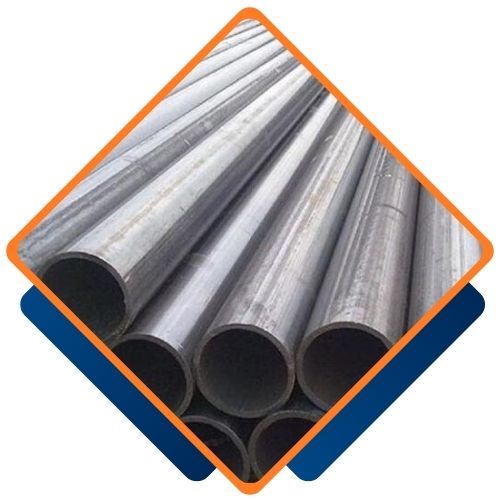

Bosega Pipes and Tubes, located in Cape Town, South Africa, has established itself as a reliable manufacturer and supplier of Stainless Steel 317 and 317L EFW (Electric Fusion Welded) Pipes. These pipes are designed to offer outstanding corrosion resistance and strength, particularly in harsh chemical and marine settings. Utilizing the electric fusion welding process, Bosega ensures that each pipe boasts excellent weld integrity, uniformity, and durability. Their 317 and 317L EFW pipes are crafted to meet rigorous international standards, making them a go-to choice for industries like chemical processing, pulp and paper, power generation, and marine engineering, where dependable performance and longevity are crucial.

Stainless Steel 317 is a high-alloy, molybdenum-rich austenitic stainless steel that provides superior resistance to chemical attacks, especially in acidic and chloride-laden environments. On the other hand, 317L is the low-carbon variant of 317, which enhances weldability and reduces the risk of intergranular corrosion after welding or exposure to high temperatures. Both grades feature elevated levels of chromium, nickel, and molybdenum compared to 316, which significantly boosts their resistance to pitting and crevice corrosion. The EFW manufacturing technique allows for the production of large-diameter pipes with consistent mechanical properties and impressive strength, making them ideal for high-pressure and corrosive applications.

| Specification | ASTM A358 / ASME SA358 |

| Specification | A / SA358 CLASS 1, A / SA358 CLASS 2, A / SA358 CLASS 3, A / SA358 CLASS 4, A / SA358 CLASS 5 |

| Grades | 304, 304L, 304H, 309S, 310S, 316, 316L, 316H, 317L, 321, 321H, 347, 347H, 904L ETC. |

| Type | EFW, ELECTRIC FUSION WELDED |

| Outer Diameter Size | Electric Fusion Welded / ERW- 8″ NB To 110″ NB (Nominal Bore Size) |

| Wall Thickness | Schedule 10 To Schedule 160 (3 mm to 100 mm Thickness) |

| Length | 01 Meter to 12.5 Meters, Single Random Length, Double Random Length And Customize Size. |

| Ends | Plain Ends / Beveled Ends |

| Delivery Conditions | As Rolled, Formed, Stress Relieved, Annealed, Hardened, Tempered |

| Coating | Electropolish, Mechanical Polish, Satin Finish, Passivated |

| Dimension | All Pipes Is Manufactured and Inspected / Tested to the Relevant standards including ASTM and ASME |

| Value Added Services | Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

| Packaging | Loose / Bundle / Wooden Pallet / Wooden Box / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector |

| Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |

| STANDARD | UNS | WERKSTOFF NR. | EN | JIS |

| SS 317 | S31700 | 1.4449 | – | SUS 317 |

| SS 317L | S31703 | 1.4438 | X2CrNiMo18-15-4 | SUS 31 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.845 min |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.89 min |

| Tensile Strength | Yield Strength (0.2%Offset) | Elongation | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | |||

| Psi – 75000, MPa – 515 | Psi – 30000, MPa – 205 | 35 % | 95 | 217 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 317 and 317L EFW Pipes from Bosega Pipes and Tubes guarantees excellent corrosion resistance, high strength, and durability. Designed for diverse industrial applications, it delivers reliable performance in tough environments while maintaining competitive pricing for cost-effective solutions.

Stainless Steel 317 and 317L EFW Pipes find extensive use in equipment for handling sulfuric acid, flue gas scrubbers, chemical transport lines, desalination plants, and pharmaceutical processing systems. Their ability to withstand harsh chemical environments, along with reliable performance at elevated temperatures, makes them perfect for demanding industrial applications. Additionally, the low carbon content in 317L helps to minimize the risk of carbide precipitation during welding, ensuring a more robust final product.

| NPS Designator | Outside Diameter | Nominal Wall Thickness | ||||||||

| in. | mm | Schedule 5SA | Schedule 10SA | Schedule 40SA | Schedule 80SA | |||||

| in. | mm | in. | mm | in. | mm | in. | mm | |||

| 8 | 8.625 | 219.08 | 0.109 | 2.77 | 0.148 | 3.76 | 0.322 | 8.18 | 0.500 | 12.70 |

| 10 | 10.750 | 273.05 | 0.134 | 3.40 | 0.165 | 4.19 | 0.365 | 9.27 | 0.500B | 12.70B |

| 12 | 12.750 | 323.85 | 0.156 | 3.96 | 0.180 | 4.57 | 0.375B | 9.52B | 0.500B | 12.70B |

| 14 | 14.000 | 355.60 | 0.156 | 3.96 | 0.188B | 4.78B | … | … | … | … |

| 16 | 16.000 | 406.40 | 0.165 | 4.19 | 0.188B | 4.78B | … | … | … | … |

| 18 | 18.000 | 457.20 | 0.165 | 4.19 | 0.188B | 4.78B | … | … | … | … |

| 20 | 20.000 | 508.00 | 0.188 | 4.78 | 0.188B | 4.78B | … | … | … | … |

| 22 | 22.000 | 558.80 | 0.188 | 4.78 | 0.218B | 5.54B | … | … | … | … |

| 24 | 24.000 | 609.60 | 0.218 | 5.54 | 0.250 | 6.35 | … | … | … | … |

| 30 | 30.000 | 762.00 | 0.250 | 6.35 | 0.312 | 7.92 | … | … | … | … |

|

Physical Properties (Room Temperature) |

||

|

Specific Heat (0-100°C) |

500 |

J.kg-1.°K-1 |

|

Thermal Conductivity |

14.6 |

W.m -1.°K-1 |

|

Thermal Expansion |

16.5 |

mm/m/°C |

|

Modulus Elasticity |

193 |

GPa |

|

Electrical Resistivity |

7.4 |

μohm/cm |

|

Density |

7.99 |

g/cm |

We offer custom sizes for Stainless Steel 317 and 317L EFW Pipes to meet your specific needs. Our dedicated team at Bosega Pipes and Tubes provides tailored solutions for all your piping and tubing requirements. For more information, contact us at sales@bosegapipes.co.za.

Stainless Steel 317 and 317L EFW Pipes is widely used in applications requiring high corrosion resistance and strength. Its primary application is in the chemical and fuel industry, where corrosive chemicals and high temperatures are dealt with. It is used in oil and gas refineries, chemical manufacturing, food processing, and pulp and paper industries. These pipelines are also good for the marine environment due to their resistance to roughness and cracks. In addition, the low carbon content of 317L makes it suitable for welded structures where it is important to prevent carbide precipitation.

©2024 Bosega Pipes and Tubes . All Rights Reserved.