Home > Stainless Steel >Stainless Steel 321 and 321H EFW Pipes

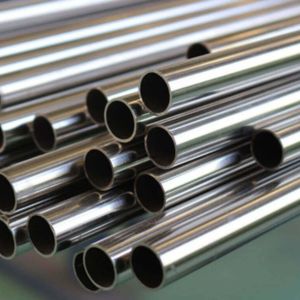

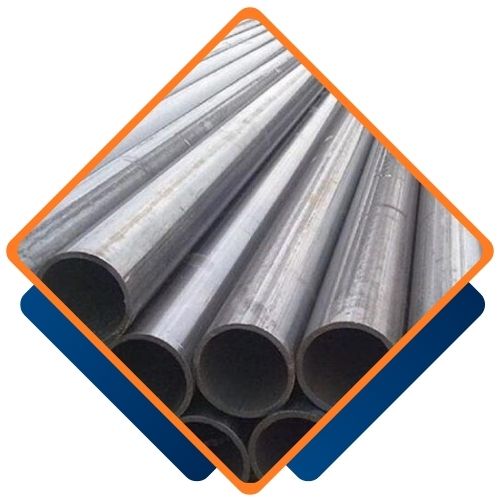

Bosega Pipes and Tubes, located in Cape Town, South Africa, specializes in providing top-notch **Stainless Steel 321 and 321H EFW Pipes** that are engineered for high-temperature and corrosion-resistant applications. These Electric Fusion Welded (EFW) pipes are particularly suited for industries where welding, heat resistance, and structural integrity are crucial. Crafted in accordance with international standards, Bosega’s 321/321H EFW pipes deliver outstanding performance in challenging environments like chemical processing, oil refineries, and thermal power plants.

Stainless Steel 321 and 321H EFW (Electric Fusion Welded) Pipe are primarily made of chromium (17-19%), nickel (9-12%), and titanium (stabilizer) The main difference between the two is that 321H has a high carbon content for high temperature strengths ( 0.04-0.10%). Both features provide excellent corrosion resistance, especially in high humidity. They have good mechanical properties such as tensile strength (515 MPa), yield strength (205 MPa), and resist stress corrosion cracking. Advantages include durability, weldability and oxidation resistance, making it ideal for heat exchangers and chemical processes.

| Specification | ASTM A358 / ASME SA358 |

| Specification | A / SA358 CLASS 1, A / SA358 CLASS 2, A / SA358 CLASS 3, A / SA358 CLASS 4, A / SA358 CLASS 5 |

| Grades | 304, 304L, 304H, 309S, 310S, 316, 316L, 316H, 317L, 321, 321H, 347, 347H, 904L ETC. |

| Type | EFW, ELECTRIC FUSION WELDED |

| Outer Diameter Size | Electric Fusion Welded / ERW- 8″ NB To 110″ NB (Nominal Bore Size) |

| Wall Thickness | Schedule 10 To Schedule 160 (3 mm to 100 mm Thickness) |

| Length | 01 Meter to 12.5 Meters, Single Random Length, Double Random Length And Customize Size. |

| Ends | Plain Ends / Beveled Ends |

| Delivery Conditions | As Rolled, Formed, Stress Relieved, Annealed, Hardened, Tempered |

| Coating | Electropolish, Mechanical Polish, Satin Finish, Passivated |

| Dimension | All Pipes Is Manufactured and Inspected / Tested to the Relevant standards including ASTM and ASME |

| Value Added Services | Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

| Packaging | Loose / Bundle / Wooden Pallet / Wooden Box / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector |

| Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |

| STANDARD | UNS | WERKSTOFF NR. | EN | JIS |

| SS 321 | S32100 | 1.4541 | X6CrNiTi18-10 | SUS 321 |

| SS 321H | S32109 | 1.4878 | X12CrNiTi18-9 | SUS 321H |

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 0.10 max | 9.00 – 12.00 | 5(C+N) – 0.70 max |

| SS 321H | 0.04 – 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 0.10 max | 9.00 – 12.00 | 4(C+N) – 0.70 max |

| Tensile Strength | Yield Strength (0.2%Offset) | Elongation | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | |||

| Psi – 75000, MPa – 515 | Psi – 30000, MPa – 205 | 35 % | 95 | 217 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

**Stainless Steel 321** is enhanced with titanium to guard against intergranular corrosion during welding and extended heat exposure, while **321H** is a high-carbon variant that offers better creep and stress rupture resistance at elevated temperatures. The EFW pipes are produced by fusing the edges of stainless steel plates or coils using high-voltage electric arcs, resulting in robust, uniform welds that are ideal for larger diameters and thinner walls. These grades boast excellent mechanical properties and oxidation resistance up to 870°C, making them perfect for transporting fluids at high temperatures.

| NPS Designator | Outside Diameter | Nominal Wall Thickness | ||||||||

| in. | mm | Schedule 5SA | Schedule 10SA | Schedule 40SA | Schedule 80SA | |||||

| in. | mm | in. | mm | in. | mm | in. | mm | |||

| 8 | 8.625 | 219.08 | 0.109 | 2.77 | 0.148 | 3.76 | 0.322 | 8.18 | 0.500 | 12.70 |

| 10 | 10.750 | 273.05 | 0.134 | 3.40 | 0.165 | 4.19 | 0.365 | 9.27 | 0.500B | 12.70B |

| 12 | 12.750 | 323.85 | 0.156 | 3.96 | 0.180 | 4.57 | 0.375B | 9.52B | 0.500B | 12.70B |

| 14 | 14.000 | 355.60 | 0.156 | 3.96 | 0.188B | 4.78B | … | … | … | … |

| 16 | 16.000 | 406.40 | 0.165 | 4.19 | 0.188B | 4.78B | … | … | … | … |

| 18 | 18.000 | 457.20 | 0.165 | 4.19 | 0.188B | 4.78B | … | … | … | … |

| 20 | 20.000 | 508.00 | 0.188 | 4.78 | 0.188B | 4.78B | … | … | … | … |

| 22 | 22.000 | 558.80 | 0.188 | 4.78 | 0.218B | 5.54B | … | … | … | … |

| 24 | 24.000 | 609.60 | 0.218 | 5.54 | 0.250 | 6.35 | … | … | … | … |

| 30 | 30.000 | 762.00 | 0.250 | 6.35 | 0.312 | 7.92 | … | … | … | … |

These pipes find common use in **refinery piping systems**, **heat exchangers**, **furnace components**, **aircraft exhaust systems**, and **superheater tubes**, where performance under thermal stress is vital. Their exceptional weldability and resistance to scaling and oxidation make them especially valuable in scenarios where standard austenitic grades might fall short. Stainless Steel 321 and 321H EFW Pipes from Bosega provide a reliable solution for industries that demand durable, high-temperature piping with consistent long-term performance.

Stainless Steel 321 and 321H EFW Pipes are widely used in high-temperature corrosion environments due to their excellent thermal resistance and mechanical strength They are commonly used in air and spacecraft exhaust systems from inside, furnace components and heat oxidizers. In the chemical and petrochemical industries, these pipelines are ideal for process equipment, heat exchangers and raw materials. The high carbon content of 321H makes it suitable for high temperature applications, such as super heaters, boilers and pressure vessels, where high tensile strength and resistance to thermal stress are required.

©2024 Bosega Pipes and Tubes . All Rights Reserved.