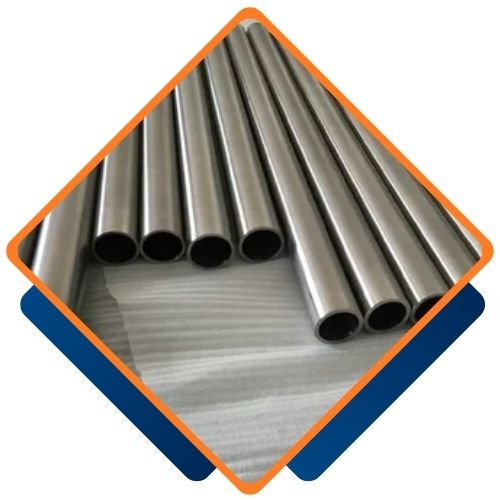

Bosega Pipes and Tubes is a well-respected manufacturer and supplier of Hastelloy Instrumentation Tubing based in Cape Town, South Africa. They provide top-notch tubing solutions designed for exceptional corrosion resistance, strength, and reliability, especially in critical process control systems. Hastelloy, which is a nickel-molybdenum-chromium alloy, is renowned for its remarkable ability to withstand both oxidizing and reducing agents, making it perfect for harsh, corrosive environments. Bosega takes pride in delivering precision-engineered tubing that features smooth internal surfaces, precise dimensions, and excellent weldability, ensuring dependable flow control and long-lasting performance in chemical, petrochemical, and marine applications.

The composition of Hastelloy Instrumentation Tubing includes about 58% nickel, up to 30% molybdenum, and up to 23% chromium, along with small amounts of tungsten, iron, and cobalt, depending on the specific grade like Hastelloy C22, C276, or B2. This unique blend offers outstanding resistance to pitting, crevice corrosion, and stress-corrosion cracking. On the mechanical side, the tubing boasts high tensile and yield strength, excellent ductility, and stability even under high pressure and temperature, ensuring it remains reliable in demanding conditions.

| Grades |

|

| Shapes | ASTM B619 Round, Rectangular, Square, Hydraulic, Straight, “U” Shape, Coiled, Honed Tubes, Pan Cake Coils |

| Manufacturing Type | Seamless / ERW / Welded / Fabricated / CDW / CDS / DOM / CEW / 100% X Ray Welded |

| Thickness Range | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXH, SCH XXS, SCH XS |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Standard | SUS, JIS, AISI, ASTM, GB, DIN, EN |

| Delivery Condition | Annealed and Pickled (AP), Polished, Bright Annealed (BA), Cold Drawn, MF and Fully Annealed |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded ASTM B622 Hastelloy Tube |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting, Moulding |

| Technique | Hastelloy Cold drawn, Cold rolled, Hot rolled, Extrusion Tube |

| Marking |

|

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

By choosing Hastelloy Instrumentation Tubing from Bosega Pipes and Tubes, you are assured of superior quality and durability. These tubes provide outstanding corrosion resistance and strength, making them ideal for a wide range of industrial applications. Our dedication to excellent service and dependable delivery ensures customer satisfaction every time. With our expertise in stainless steel products, we deliver top-tier solutions customized to meet your specific requirements.

Bosega Pipes and Tubes, a leading supplier of Hastelloy Instrumentation Tubing in Cape Town, South Africa, provides a wide selection of premium pipes and tubes for diverse industrial applications. With a vast inventory and a strong focus on delivering outstanding service, they are the preferred choice for stainless steel products in the region.

At Bosega Pipes and Tubes, we provide custom sizes of Hastelloy Instrumentation Tubing to meet your exact specifications. Our dedicated team is here to offer tailored solutions for all your piping and tubing needs. For more information, feel free to reach out to us at sales@brydonpipesandtubes.co.uk.

Hastelloy Instrumentation Tubing finds its place in various industries, including chemical processing, power generation, oil and gas, pharmaceuticals, and marine engineering. It’s particularly suited for applications such as control lines, measurement systems, pressure gauges, and flow meters that operate in corrosive and high-pressure settings. The combination of corrosion resistance, mechanical strength, and precise dimensions makes Hastelloy Instrumentation Tubing a top choice for critical and high-performance industrial systems.

©2024 Bosega Pipes and Tubes . All Rights Reserved.