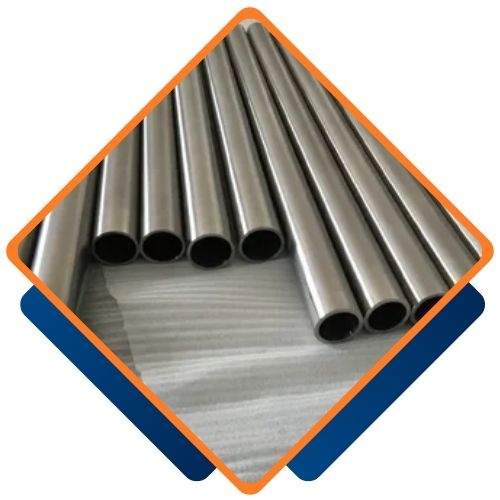

Bosega Pipes and Tubes, located in Cape Town, South Africa, has earned a solid reputation as a reliable manufacturer and supplier of top-notch Titanium Welded Tubing. With a strong focus on quality and innovation, they deliver tubing solutions that adhere to international standards for strength, durability, and resistance to corrosion. Known for its impressive performance in tough environments, Bosega’s Titanium Welded Tubing is perfect for industries like chemical processing, marine, aerospace, and power generation. The company prides itself on precision engineering, dependable delivery, and outstanding customer service, catering to the varied needs of clients both in South Africa and beyond.

This Titanium Welded Tubing is mainly made from titanium, with small amounts of elements like aluminum, vanadium, or molybdenum added to boost its strength and corrosion resistance. It boasts a high strength-to-weight ratio, excellent formability, and remarkable resistance to oxidation and stress corrosion cracking. In terms of mechanics, the tubing shows tensile strength between 350–550 MPa and good ductility, making it a great choice for high-performance and critical applications that require lightweight yet robust materials in extreme conditions.

| Sizes: Tube and Tubing Full Range of sizes in all grades | GRADE | SPECIFICATIONS |

|---|---|---|

| Ti CP-GRADE 2,3,4 | AMS-4941, 4942, BMS-7-21, DMS-1872, 1874, 1898 | |

| 3AL-2.5V | AMS-4944, 4943, 4945, DMS-2241, B50TF35, PWA-1260 | |

| Titanium Tubing Specifications: AMS 4935, DMS 1650, MIL-T 9047, MIL-T 81556, MMS 1202, AIMS 03-18-011, AMS 4975 (chemistry only) | ||

| Element | Titanium | Nitrogen | Carbon | Hydrogen | Iron | Oxygen | Residuals (each) | Residuals (total) |

|---|---|---|---|---|---|---|---|---|

| % | Balance | 0.03 max | 0.08 max | 0.015 max | 0.30 max | 0.25 max | 0.1 max | 0.4 max |

| Titanium Tube | 0.2% Proof Stress | Tensile Strength | Elongation |

|---|---|---|---|

| MPa | MPa | % | |

| Annealed | 275-450 | 345 | 20 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

By choosing Titanium Welded Tubing from Bosega Pipes and Tubes, you are assured of superior quality and durability. These tubes provide outstanding corrosion resistance and strength, making them ideal for a wide range of industrial applications. Our dedication to excellent service and dependable delivery ensures customer satisfaction every time. With our expertise in stainless steel products, we deliver top-tier solutions customized to meet your specific requirements.

Bosega Pipes and Tubes, a leading supplier of Titanium Welded Tubing in Cape Town, South Africa, provides a wide selection of premium pipes and tubes for diverse industrial applications. With a vast inventory and a strong focus on delivering outstanding service, they are the preferred choice for stainless steel products in the region.

At Bosega Pipes and Tubes, we provide custom sizes of Titanium Welded Tubing to meet your exact specifications. Our dedicated team is here to offer tailored solutions for all your piping and tubing needs. For more information, feel free to reach out to us at sales@brydonpipesandtubes.co.uk.

You’ll find Titanium Welded Tubing widely used in industries that need exceptional corrosion resistance and high strength. In aerospace, it’s found in hydraulic systems, exhaust ducts, and structural frameworks. In the chemical and marine sectors, it’s utilized in heat exchangers, condensers, and piping systems that come into contact with seawater and harsh chemicals. It’s also employed in power plants, medical equipment, and desalination units, where reliability, longevity, and resistance to high temperatures are crucial. Its lightweight and non-reactive characteristics make it a fantastic fit for both industrial and commercial applications.

©2024 Bosega Pipes and Tubes . All Rights Reserved.