Home > Stainless Steel > Stainless steel 304 Welded Tubing

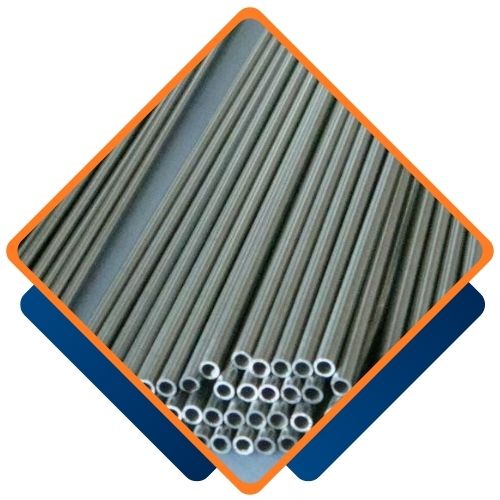

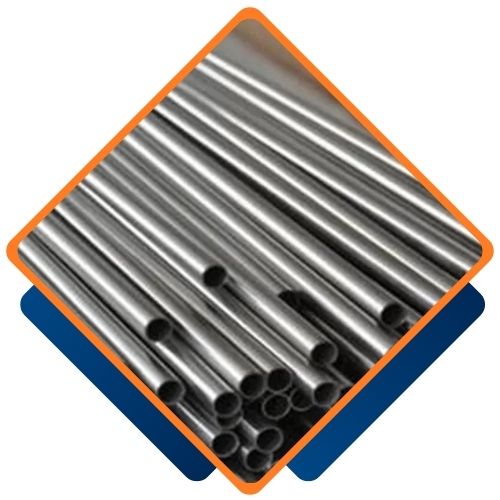

Bosega Pipes and Tubes, located in Cape Town, South Africa, stands out as a top manufacturer and supplier of high-quality Stainless Steel 304 Welded Tubing. This tubing is celebrated for its remarkable corrosion resistance, durability, and precision, making it perfect for the rigorous demands of various industrial applications. At Bosega, we utilize cutting-edge manufacturing techniques and maintain strict quality control to guarantee dimensional accuracy, smooth finishes, and long-lasting performance. Our 304 welded tubing is widely utilized in the chemical, pharmaceutical, food processing, and marine industries, providing dependable mechanical strength, hygiene, and oxidation resistance—essential features for piping systems and instrumentation where safety and efficiency are paramount.

Stainless Steel 304 Welded Tubing is an austenitic stainless steel alloy that contains 18–20% chromium and 8–12% nickel, which gives it outstanding resistance to corrosion and oxidation. The welded design ensures structural integrity and precise dimensions. It boasts a tensile strength of about 515 MPa, a yield strength of around 205 MPa, and an elongation of 40%. With its excellent toughness, formability, and mechanical stability, this tubing is well-suited for moderate to demanding industrial environments where durability, reliability, and resistance to oxidizing agents are crucial.

| Tube Range | 1/2″ OD – 12″ OD, Guage: 25 SWG – 10 SWG |

| Outer Diameter | 3.00 mm – 219.10 mm |

| Wall Thickness | 0.40 mm – 12.70 mm |

| Schedules | 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH |

| Length | Upto 30 meters, Custom Cut Lengths |

| Specifications | ASTM A213 / ASTM SA213 |

| Types | Round, Square, Rectangle, Coil, “U” Shape, Hydraulic & Honed Tubes |

| SS | 304 |

|---|---|

| Ni | 8 – 11 |

| Fe | Balance |

| Cr | 18 – 20 |

| C | 0.08 max |

| Si | 0.75 max |

| Mn | 2 max |

| P | 0.040 max |

| S | 0.030 max |

| Grade | 304 |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 40 |

| Hardness | |

| Rockwell B (HR B) max | 92 |

| Brinell (HB) max | 201 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choose Stainless Steel 304 Welded Tubing from Bosega Pipes and Tubes for exceptional corrosion resistance, superior strength and excellent durability. Ideal for a variety of industrial applications it provides outstanding performance in harsh environments. With precision manufacturing and quality assurance, we ensure reliable and durable tubing solutions.

Bosega Pipes and Tubes is the largest supplier of Stainless Steel 304 Welded Tubing in Cape Town, South Africa. Known for its high-quality products. We offer superior corrosion resistance, strength, and durability. Trusted by industries worldwide they provide reliable precision-engineered tubing for various applications and project needs.

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 304 | S30400 | 304S31 | 58E | 1.4301 | X5CrNi18-10 | 2332 | SUS 304 |

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

| 0-1000C | 0-3150C | 0-5380C | at 1000C | at 5000C | |||||

| 304 | 8000 | 193 | 17.2 | 17.8 | 18.4 | 16.2 | 21.5 | 500 | 720 |

Yes, Bosega Pipes and Tubes offer large custom designs for Stainless Steel 304 Welded Tubing. With design, wall thickness and length. Their adjustable options ensure the tubing meets specific application requirements. This flexibility makes it more efficient and reliable for different industries and environments. For more details, contact us at sales@bosegapipes.co.za.

This Stainless Steel 304 Welded Tubing is commonly found in industries that require corrosion-resistant, durable, and hygienic tubing solutions. Typical applications include chemical and petrochemical plants, pharmaceutical equipment, food and beverage processing lines, heat exchangers, and water treatment systems. Its smooth internal surface promotes efficient fluid flow and minimizes contamination risks. Thanks to its excellent weldability and formability, it can be easily fabricated and installed in complex piping systems. The tubing’s long-lasting corrosion resistance, mechanical strength, and reliability make it a top choice for safe and efficient operations in various industrial and structural applications.

©2024 Bosega Pipes and Tubes . All Rights Reserved.