Home > Stainless Steel > Stainless steel 304H Welded Tubing

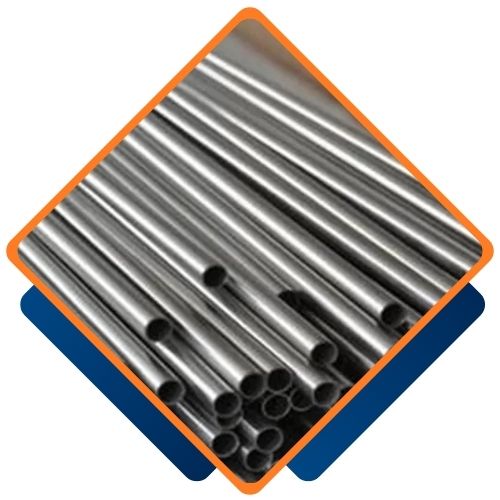

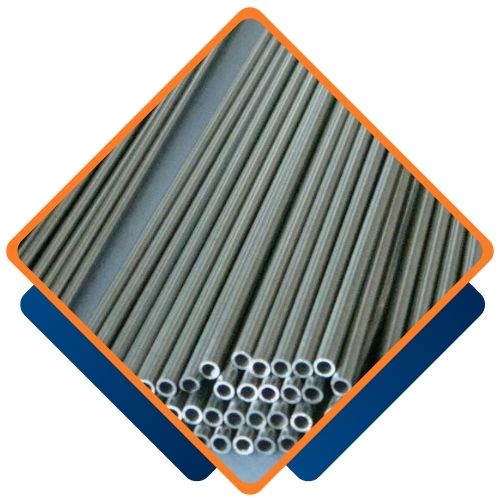

Bosega Pipes and Tubes is a top-notch manufacturer and supplier located in Cape Town, South Africa, focusing on high-quality Stainless Steel 304H Welded Tubing. This tubing is designed to withstand high temperatures, offering impressive strength, durability, and outstanding resistance to corrosion. Each piece is crafted with precision to meet the toughest industrial standards. Bosega employs cutting-edge welding techniques along with rigorous quality control to ensure seamless performance, accurate dimensions, and a long lifespan. It’s widely utilized in industries like chemical, petrochemical, power generation, and food processing, where 304H welded tubing guarantees reliable thermal performance, resistance to oxidation, and mechanical stability—making it perfect for critical piping and instrumentation systems in demanding environments.

Stainless Steel 304H Welded Tubing is an austenitic stainless steel alloy that contains 18–20% chromium, 8–12% nickel, and a higher carbon content compared to 304L, which boosts its high-temperature strength and creep resistance. The welded design ensures it maintains structural integrity and precise dimensions. It boasts a tensile strength of about 515 MPa, a yield strength of around 205 MPa, and an elongation of 40%. This tubing is known for its excellent corrosion resistance, toughness, and mechanical stability, making it ideal for extended exposure to high temperatures and harsh industrial conditions while ensuring reliability and durability.

| Specifications | : | ASTM A/ASME SA213/ A269/ A249 |

| Dimensions | : | ASTM, ASME and API |

| SS 304H Tubing Size | : | 1/8″ NB TO 30″ NB IN |

| Thickness | : | 0.35mm to 6.35mm OD in thickness ranging from 0.1mm to 1.2mm. |

| Type | : | Seamless / ERW / Fabricated / Welded / LSAW Tubes |

| Schedule | : | SCH20, SCH30, SCH40, XS, SCH60, STD, SCH80, SCH80, SCH120, SCH140, SCH160, XXS |

| Length | : | Single Random, Double Random & Cut Length. |

| Form | : | Round, Square, Rectangular, Hydraulic. |

| End | : | Plain End, Beveled End, Treaded |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304H | 0.10 max | 2.0 max | 0.75 max | 0.045 max | 0.03 max | 18 – 20 | – | 8 – 10.5 | – |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choose Stainless Steel 304H Welded Tubing from Bosega Pipes and Tubes for exceptional corrosion resistance, superior strength and excellent durability. Ideal for a variety of industrial applications it provides outstanding performance in harsh environments. With precision manufacturing and quality assurance, we ensure reliable and durable tubing solutions.

Bosega Pipes and Tubes is the largest supplier of Stainless Steel 304H Welded Tubing in Cape Town, South Africa. Known for its high-quality products. We offer superior corrosion resistance, strength, and durability. Trusted by industries worldwide they provide reliable precision-engineered tubing for various applications and project needs.

| STANDARD | WERKSTOFF NR. | UNS |

| SS 304H | 1.4948 | S30409 |

Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

0-1000C | 0-3150C | 0-5380C | at 1000C | at 5000C | |||||

304H | 8000 | 193 | 17.2 | 17.8 | 18.4 | 16.2 | 21.5 | 500 | 720 |

Yes, Bosega Pipes and Tubes offer large custom designs for Stainless Steel 304H Welded Tubing. With design, wall thickness and length. Their adjustable options ensure the tubing meets specific application requirements. This flexibility makes it more efficient and reliable for different industries and environments. For more details, contact us at sales@bosegapipes.co.za.

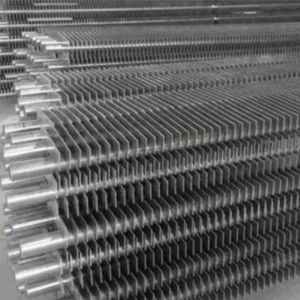

You’ll find Stainless Steel 304H Welded Tubing in various industries that demand high-temperature resistance, mechanical strength, and corrosion protection. It’s commonly used in heat exchangers, boiler tubes, chemical reactors, petrochemical piping systems, and power generation equipment. Thanks to its welded construction, it allows for efficient fabrication and installation, while its superior oxidation and corrosion resistance guarantees long-lasting durability under thermal and chemical stress. This tubing is also a great fit for food processing, pharmaceutical, and marine applications, where hygiene and structural integrity are paramount.

©2024 Bosega Pipes and Tubes . All Rights Reserved.