Home > Stainless Steel > Stainless Steel 316Ti Welded Tubing

Bosega Pipes and Tubes, located in Cape Town, South Africa, stands out as a premier supplier of **Stainless Steel 316Ti Welded Tubing**. This tubing is specifically engineered for applications that demand exceptional corrosion resistance, strength, and stability even at high temperatures. The titanium-stabilized variant of 316 stainless steel provides enhanced protection against intergranular corrosion, especially after welding or extended exposure to heat. Manufactured to meet international standards, Bosega’s 316Ti welded tubing guarantees top-notch performance across a diverse array of industrial applications.

Stainless Steel 316Ti Welded Tubing contains 16-18% chromium, 10-14% nickel, 2-3% molybdenum, and 0.5-1.0% titanium, which stabilizes the material against sensitization. It offers excellent mechanical properties including a tensile strength of 515 MPa and yield strength of 205 MPa. Along with superior resistance to pitting and crevice corrosion, particularly in chloride-rich environments. This tubing is known for its high strength, exceptional corrosion resistance, and excellent weldability making it ideal for use in chemical processing, marine environments, and food processing applications.

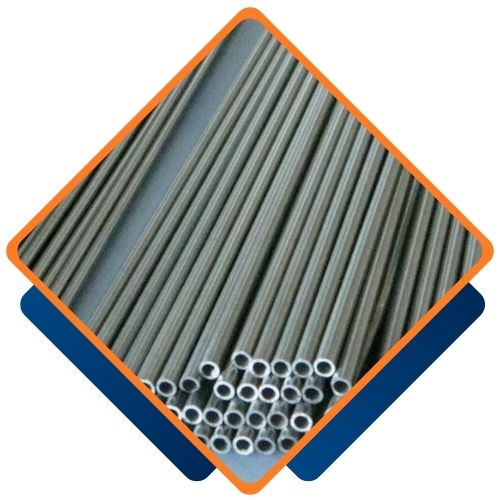

Tube Range : 6.35 mm OD To 101.6 mm OD Guage: 25 SWG – 10 SWG

Outer Diameter : 3.00 mm – 219.10 mm

Wall Thickness : 0.40 mm – 12.70 mm

Schedules : 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH

Length : Upto 30 meters, Custom Cut Lengths

Specifications : ASTM A269 / ASTM SA269

Types : Round, Square, Rectangle, Coil, “U” Shape, Hydraulic & Honed Tubes

| SS | 316TI |

| Ni | 10 – 14 |

| N | 0.10 max |

| Cr | 16 – 18 |

| C | 0.08 max |

| Si | 0.75 max |

| Mn | 2 max |

| P | 0.045 max |

| S | 0.030 max |

| Mo | 2.00 – 3.00 |

| Grade | 316TI |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 35 |

| Hardness | |

| Rockwell B (HR B) max | 75 |

| Brinell (HB) max | 205 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

**Stainless Steel 316Ti** is enriched with molybdenum, which boosts its resistance to pitting and crevice corrosion. The inclusion of titanium plays a crucial role in stabilizing the structure against carbide formation, particularly in the heat-affected zones. The process of creating welded tubing involves shaping stainless steel strips into cylindrical forms and expertly joining the edges through advanced welding techniques. This method not only allows for cost-effective production but also ensures consistent wall thickness, smooth internal surfaces, and outstanding mechanical properties, making it an excellent choice for medium- to high-pressure systems.

Bosega Pipes and Tubes is the largest supplier of Stainless Steel 316Ti Welded Tubing in Cape Town, South Africa. Known for its high-quality products. We offer superior corrosion resistance, strength, and durability. Trusted by industries worldwide they provide reliable precision-engineered tubing for various applications and project needs.

| STANDARD | UNS | WERKSTOFF NR. | JIS | AFNOR | BS | GOST | EN |

| SS 316TI | S31635 | 1.4571 | SUS 316TI | Z6CNDT17‐12 | 320S31 | 08Ch17N13M2T | X6CrNiMoTi17-12-2 |

You’ll find 316Ti welded tubing widely utilized in **chemical processing equipment**, **heat exchangers**, **food and beverage systems**, **pharmaceutical production**, and **marine applications**. In these settings, corrosion resistance, weldability, and structural integrity are paramount. It excels in environments rich in chlorides and acids, maintaining its strength even at elevated temperatures. With Stainless Steel 316Ti Welded Tubing from Bosega, you’re assured of a reliable and efficient solution for industries that require long-lasting durability and resilience against harsh operating conditions.

| Specific Heat (0-100°C) | Thermal Conductivity | Thermal Expansion | Modulus Elasticity | Electrical Resistivity | Density |

| 500 | 14.6 | 16.5 | 193 | 7.4 | 7.99 |

| J.kg-1.°K-1 | W.m -1.°K-1 | mm/m/°C | GPa | μohm/cm | g/cm3 |

Stainless Steel 316Ti Welded Tubing is widely used in industries requiring superior corrosion resistance and high strength. It is ideal for chemical processing, marine environments, and food processing applications. Where resistance to pitting, crevice corrosion, and high temperatures is crucial. This tubing is also used in heat exchangers, reactors, and pressure vessels, providing reliable performance in aggressive environments. Its excellent weldability and durability make it a preferred choice for industries like petrochemical, pharmaceuticals, and power generation, ensuring long-lasting service in demanding conditions.

©2024 Bosega Pipes and Tubes . All Rights Reserved.