Home > Stainless Steel > Stainless Steel Corrugated Tubing

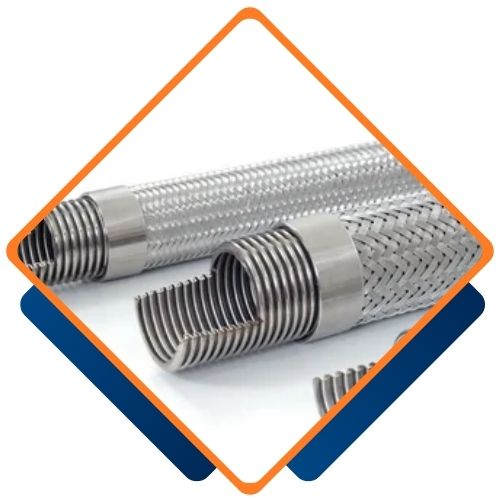

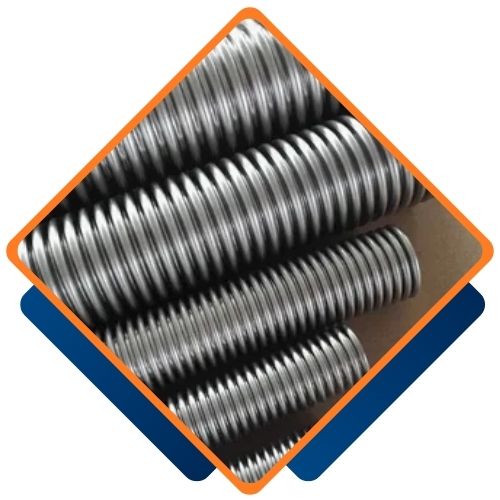

Bosega Pipes and Tubes, based in Cape Town, South Africa, offers top-notch **Stainless Steel Corrugated Tubing** that’s built for flexibility, durability, and resilience in tough environments. This tubing features a unique corrugated design that allows it to bend easily without sacrificing strength or integrity, making it a fantastic choice for situations where movement, vibration, or tight spaces come into play. Bosega is committed to ensuring that every product adheres to rigorous industry standards, providing dependable solutions for fluid and gas transfer across a variety of sectors.

Stainless Steel Corrugated Tubing is typically made from 304 or 316 stainless steel, offering high chromium (18-20%) and nickel (8-12%) content for enhanced corrosion resistance. Mechanically, it boasts tensile strengths around 515 MPa, high flexibility, and excellent durability under pressure, making it ideal for high-stress applications. The tubing’s corrugated design enables superior flexibility, ease of installation, and vibration absorption, reducing connection stress. It is corrosion-resistant, durable, and efficient for transporting gases or liquids, particularly in HVAC, chemical, and petrochemical industries.

| Size Range | 6.35 mm To 50.8 mm OD |

| Length | As per Customer requirement, Maximum upto 22 Meter Long. |

| Thickness | 0.50 mm TO 6.0 mm |

| Dimenisons | ASTM,AISI,ASME,JIS,DIN,EN,GB,BS,SUS |

| Standard | ASTM A / ASME SA213 |

| Material | SS 304, SS 304L,SS 316,SS 316L |

| Form | Round, Square, Rectangular, Coil, U Tube, Pan Cake. |

| Shapes | Straight tube, Coil tubing |

| Type | As Welded, EFW, ERW, Seamless, Semi Seamless, Bead Removed |

| Finish | SS cottugated tubes and corrugated pipes can be supplied in mechanical polished with various grits like at 80, 120, 240, 320, 400, 600 grit and mirror polished. |

| Packing | Sleeved, Ends Capped, Wooden Boxed |

| STAINLESS STEEL CORRUGATED TUBE GRADES | UNS | C | Mn | P | S | Si | Cr | Ni | Mo | Ti | Nb | N |

| TP304 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ||||

| TP304L | S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | ||||

| TP316 | S3160 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |||

| TP316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| Material | Heat | Temperure | Tensile Strength | Yield Strength | Elongation %, Min |

| Treatment | Min. | Ksi (MPa), Min. | Ksi (MPa), Min. | ||

| º F(º C) | |||||

| TP304 | Solution | 1900 (1040) | 75(515) | 30(205) | 35 |

| TP304L | Solution | 1900 (1040) | 70(485) | 25(170) | 35 |

| TP316 | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

| TP316L | Solution | 1900(1040) | 70(485) | 25(170) | 35 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

| GRADE | UNS NO | DIN/WERKSTOFF |

|---|---|---|

| 304 | S30400 | 1.4301 |

| 304H | S30409 | – |

| 304L | S30403 | 1.4306 |

| 310S | S31008 | 1.4845 |

| 316S | S31600 | 1.4436 |

| 316H | S31609 | – |

| 316 TI | S31635 | 1.4571 |

| 316L (2.5 MIN MOLY) | S31603 | 1.4435 |

| 316L | S31603 | 1.4404 |

| 317L | S31703 | 1.4438 |

| 321 | S32100 | 1.4541 |

| 321H | S32109 | – |

| 347 | S34700 | 1.4550 |

Typically crafted from high-quality grades like 304 or 316L stainless steel, **Stainless Steel Corrugated Tubing** boasts impressive corrosion resistance, mechanical strength, and thermal stability. The corrugated structure enhances flexibility and accommodates expansion and contraction due to temperature fluctuations, all while withstanding high pressures. Depending on the specific application’s needs for pressure and mechanical protection, it can be used with or without a protective braiding. The smooth internal bore guarantees consistent flow characteristics, even in dynamic or high-frequency settings.

This tubing finds its place in **HVAC systems**, **gas and fluid transmission**, **solar heating systems**, **chemical plants**, and **industrial machinery**, where resistance to corrosion, heat, and pressure is essential. It’s also a go-to choice for **automotive**, **marine**, and **residential plumbing applications** that require both flexibility and reliability. With Bosega’s Stainless Steel Corrugated Tubing, you get an efficient and durable solution for connecting components in systems that face thermal cycling, vibration, or space limitations, all while ensuring safe and uninterrupted flow performance.

| SIZE OD | NOMINAL WALL THICKNESS | OUTSIDE DIAMETER TOLERANCE | LENGTH TOLERANCE | WALL THICKNESS TOLERANCE | ||||

|---|---|---|---|---|---|---|---|---|

| (in) | (mm) | (in) | (mm) | (in) | (mm) | (in) | (mm) | (%) |

| ½ | 12.7 | 0.065 | 1.65 | +/-0.005 | +/-0.13 | +⅛, -0 | +3.18, -0 | +/-10.0% |

| ¾ | 19.1 | 0.065 | 1.65 | +/-0.005 | +/-0.13 | +⅛, -0 | +3.18, -0 | +/-10.0% |

| 1 | 25.4 | 0.065 | 1.65 | +/-0.005 | +/-0.13 | +⅛, -0 | +3.18, -0 | +/-10.0% |

| 1½ | 38.1 | 0.065 | 1.65 | +/-0.008 | +/-0.20 | +⅛, -0 | +3.18, -0 | +/-10.0% |

| 2 | 50.8 | 0.065 | 1.65 | +/-0.008 | +/-0.20 | +⅛, -0 | +3.18, -0 | +/-10.0% |

| 2½ | 63.5 | 0.065 | 1.65 | +/-0.010 | +/-0.25 | +⅛, -0 | +3.18, -0 | +/-10.0% |

| 3 | 76.2 | 0.065 | 1.65 | +/-0.010 | +/-0.25 | +⅛, -0 | +3.18, -0 | +/-10.0% |

| 4 | 101.6 | 0.083 | 2.11 | +/-0.015 | +/-0.38 | +⅛, -0 | +3.18, -0 | +/-10.0% |

| 6 | 152.4 | 0.109 | 2.77 | +/-0.030 | +/-0.76 | +1, -0 | +25.4, -0 | +/-10.0% |

Yes, we offer custom sizes for Stainless Steel Corrugated Tubing to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

Stainless steel corrugated tubing is widely used across industries for its flexibility, durability, and corrosion resistance. In the HVAC and refrigeration sectors, it efficiently transports refrigerants and gases, while in plumbing, it safely channels water and other fluids. Its resilience to high pressures and temperatures makes it ideal for chemical processing and oil and gas applications, where it handles aggressive fluids and gases. Additionally, it finds applications in automotive exhaust systems, power generation, and renewable energy setups, delivering reliable performance in demanding environments.

©2024 Bosega Pipes and Tubes . All Rights Reserved.