Home > Stainless Steel > Stainless Steel 904L Tubing

Bosega Pipes and Tubes, located in Cape Town, South Africa, has earned a solid reputation as a reliable manufacturer and supplier of top-notch Stainless Steel 904L Tubing. Known for its outstanding corrosion resistance and impressive mechanical strength, this tubing is built to thrive in extreme conditions. At Bosega, every product is crafted to meet international standards, providing precision-engineered tubing that caters to critical industries. Their Stainless Steel 904L Tubing is perfect for sectors like chemical processing, marine, and oil refining, where durability and resistance to harsh environments are vital for long-lasting performance and safety.

Stainless Steel 904L Tubing is an austenitic stainless steel that boasts high levels of chromium, nickel, molybdenum, and copper. This special blend gives it remarkable resistance to pitting, crevice corrosion, and stress cracking, even in tough environments. It has a tensile strength of about 490 MPa, a yield strength of roughly 220 MPa, and an elongation of 35%. Plus, it retains its toughness even in sub-zero temperatures, making it ideal for demanding industrial applications that require both strength and corrosion resistance.

| Marking | All Stainless Steel 904L tubes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

|---|---|

| 904L Stainless Steel Seamless Tube Size | 3.35 mm OD To 101.6 mm OD |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| SS 904L tube Length | Single Random, Double Random, Standard & Cut length |

| 904L Stainless Steel Tube Type | Seamless, ERW, EFW, Welded, Fabricated |

| Stainless Steel 904L Tube Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

| 904L Stainless Steel tube Form | Round, Coil, Square, Rectangular, Boiler, Hydraulic, Straight or ‘U’ bent Tubes, Hollow, LSAW Tubes Etc. |

| 904L Stainless Steel Welded Tube Size | 6.35 mm OD To 152 mm OD |

| End | Plain End, Beveled End, Treaded |

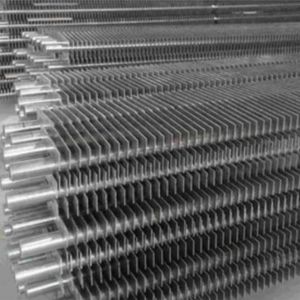

| Specialize in | 904L Stainless Steel Capillary Tube & Other Odd Size 904L Stainless Steel Heat Exchanger & Condenser Tubes |

| Application | Oil Tube, Gas Tube, Fluid Tube, Boiler and Heatexchanger |

| 904L Stainless Steel Tube Standards | ASTM B/ASME SB674 / SB677 |

| Test Certificate | Manufacturer Test Certificate Laboratory Test Certificate from Govt. Approved Lab. Under Third Party Inspection |

| 904L Stainless Steel tubing wall thickness | 0.020″ –0.220″, (special wall thicknesses available) |

| Grade | C | Mn | Si | P | S | Cr | MO | Ni | Cu | |

| 904L | min. | – | – | – | – | – | 19.0 | 4.0-5.0 | 23.0 | 1.0 |

| max. | 0.20 | 2.0 | 1.0 | 0.045 | 0.035 | 23.0 | 28.0 | 2.0 | ||

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 904L | 490 | 220 | 35 | 70-90 typical | – |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

You’ll find Stainless Steel 904L Tubing widely used across various industries, including chemical and petrochemical processing, pulp and paper production, marine engineering, and gas scrubbing plants. Its excellent corrosion resistance makes it suitable for handling sulfuric, phosphoric, and acetic acids. It’s also commonly used in heat exchangers, condensers, and pressure vessels where high resistance to chloride attack is crucial. With its durability and low maintenance needs, this tubing is a go-to choice for long-term use in both industrial and marine settings.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel 904L Tubing in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel 904L Tubing to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

Stainless steel 904L tubing is widely used in applications requiring exceptional corrosion resistance and strength. Ideal for sulfuric, phosphoric and acetic acids used in the chemical industry. The oil and gas industry uses these pipelines both offshore and onshore because of their resistance to chloride pressure. It is used to process strong chemicals and transport them through chemical and petrol stations. In addition, they are used in seawater cooling equipment, heat exchangers and pulp and paper applications equipment, where durability and resistance to harsh environments are crucial.

©2024 Bosega Pipes and Tubes . All Rights Reserved.