Home > Stainless Steel > Stainless Steel 316Ti Seamless Pipes

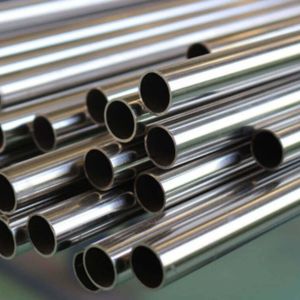

Bosega Pipes and Tubes, based in Cape Town, South Africa, specializes in high-performance **Stainless Steel 316Ti Seamless Pipes** that are engineered for demanding applications requiring exceptional corrosion resistance and strength at high temperatures. These pipes are particularly well-suited for sectors like chemical processing, marine engineering, and heat exchanger systems. Adhering to international quality standards, Bosega guarantees that each seamless pipe delivers outstanding dimensional accuracy, internal cleanliness, and long-lasting reliability.

Stainless Steel 316Ti Seamless Pipes contain iron, chromium (16-18%), nickel (10-14%), molybdenum (2-3%) and up to titanium (0.7%) to increase their corrosion resistance and strength Mechanical characteristics 290 MPa Includes yield strength, 515 MPa tensile strength, and 40% elongation. The addition of titanium improves the corrosion resistance, making this tube ideal for high temperature applications. Benefits include excellent corrosion resistance in turbulent environments, high strength, durability, and the ability to maintain structural integrity under extreme conditions, making it suitable for industrial applications of the various components.

Range : 6NB to 1200NB

Outer Diameter : 1/8″ NPS to 12″ NPS

Thickness : 0.6 mm to 12.7 mm

Schedules : SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS.

Length : Single Random, Double Random & Cut Length

Specifications : ASTM A312 / ASTM SA312

Types : Round, Square, Rectangle, Hydraulic, Honed Tubes

End : Plain End, Beveled End

| STANDARD | UNS | WERKSTOFF NR. | JIS | AFNOR | BS | GOST | EN |

| SS 316TI | S31635 | 1.4571 | SUS 316TI | Z6CNDT17‐12 | 320S31 | 08Ch17N13M2T | X6CrNiMoTi17-12-2 |

| Ni | 10 – 14 |

| N | 0.10 max |

| Cr | 16 – 18 |

| C | 0.08 max |

| Si | 0.75 max |

| Mn | 2 max |

| P | 0.045 max |

| S | 0.030 max |

| Mo | 2.00 – 3.00 |

| Grade | 316TI |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 35 |

| Hardness | |

| Rockwell B (HR B) max | 75 |

| Brinell (HB) max | 205 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

**Stainless Steel 316Ti** is a titanium-stabilized variant of 316, providing remarkable resistance to intergranular corrosion, even after being subjected to high temperatures during welding or prolonged use. The addition of titanium helps prevent the formation of chromium carbides, ensuring corrosion resistance in the heat-affected zone. The seamless design guarantees consistent strength throughout the pipe, eliminates the risk of weld defects, and enables the material to endure high pressure and thermal stress — making it an excellent choice for transporting corrosive fluids or gases in challenging environments.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel 316Ti Seamless Pipes in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

| SS Grade | UNS No | Old British | Euronorm | GOST | JIS – Japanese | ||

| BS | En – European | WNR. No | AFNOR | ||||

| 316Ti | UNS S31635 | 320S31 | X6CrNiMoTi17-12-2 | 1.4571 | Z6CNDT17‐12 | 08Ch17N13M2T | SUS 316Ti |

| Specific Heat (0-100°C) | Thermal Conductivity | Thermal Expansion | Modulus Elasticity | Electrical Resistivity | Density |

| 500 | 14.6 | 16.5 | 193 | 7.4 | 7.99 |

| J.kg-1.°K-1 | W.m -1.°K-1 | mm/m/°C | GPa | μohm/cm | g/cm3 |

These pipes find extensive application in **chemical plants**, **oil and gas systems**, **pharmaceutical processing**, **food and beverage industries**, and **marine applications**, where exposure to chlorides, acids, and high heat is prevalent. They also excel in **heat exchangers**, **condensers**, and **pressure vessels**, thanks to their structural integrity and resistance to scaling. Stainless Steel 316Ti Seamless Pipes from Bosega provide a robust and cost-effective solution for industries that require top-notch performance under extreme operating conditions.

Stainless Steel 316Ti Seamless Pipes are widely used in various industries due to their corrosion resistance and high strength. Typical applications are in the chemical industry, oil and gas production, marine environment, and pharmaceutical manufacturing. These pipes are ideal for pressurized water, heat exchangers and tanks. Furthermore, their durability makes them suitable for the food processing and dairy industries, where cleaning and resistance to aggressive cleaning agents are required Overall, the lack of 316Ti pipe cables are essential for any application that requires reliable operation under harsh conditions.

©2024 Bosega Pipes and Tubes . All Rights Reserved.