Home > Stainless Steel > Stainless Steel 904L Seamless Pipes

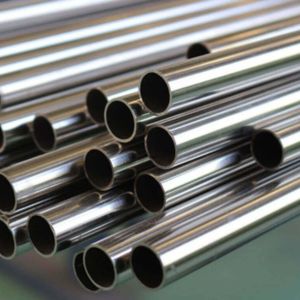

Bosega Pipes and Tubes, located in Cape Town, South Africa, stands out as a reliable supplier of top-notch **Stainless Steel 904L Seamless Pipes**, crafted for use in highly corrosive and demanding settings. Renowned for their remarkable strength and resistance to corrosion, these pipes find their place in various industries, including chemical processing, marine engineering, pharmaceutical production, and oil and gas. Bosega guarantees that all 904L seamless pipes adhere to rigorous international standards, providing customers with precision, durability, and a long lifespan, even in the toughest operating conditions.

Stainless Steel 904L Seamless Pipes are rich in nickel and chromium, containing about 19% nickel and 23% chromium, and molybdenum and copper for increased corrosion resistance Their mechanical properties have good tensile strength, with a yield strength of about 220 MPa and a tensile strength of 520 MPa Pitting and cravis provide excellent corrosion resistance, making them ideal for harsh environments, such as chemical processing and marine applications in addition they exhibit excellent weldability and formability, which checks recognize versatility in a variety of industrial applications.

Range : 6NB to 1200NB

Outer Diameter : 1/8″ NPS to 12″ NPS

Thickness : 0.6 mm to 12.7 mm

Schedules : SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS.

Length : Single Random, Double Random & Cut Length

Specifications : ASTM B677 / ASTM SB677

Types : Round, Square, Rectangle, Hydraulic, Honed Tubes

End : Plain End, Beveled End

| STANDARD | UNS | WERKSTOFF NR. | JIS | AFNOR | BS | KS | EN |

| SS 904L | N08904 | 1.4539 | SUS 890L | Z2 NCDU 25-20 | 904S13 | STS 317J5L | X1NiCrMoCu25-20-5 |

| Ni | 23 – 28 |

| Cu | 1.00 – 2.00 |

| Cr | 19 – 23 |

| C | 0.20 max |

| Si | 1 max |

| Mn | 2 max |

| P | 0.045 max |

| S | 0.035 max |

| Mo | 4.00 – 5.00 |

| Grade | 904L |

| Tensile Strength (MPa) min | 490 |

| Yield Strength 0.2% Proof (MPa) min | 220 |

| Elongation (% in 50mm) min | 35 |

| Hardness | |

| Rockwell B (HR B) max | 92 |

| Brinell (HB) max | – |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

**Stainless Steel 904L** is a non-stabilized austenitic stainless steel alloy characterized by low carbon content and elevated levels of chromium, nickel, molybdenum, and copper. These elements contribute to the material’s exceptional resistance to strong reducing acids, such as sulfuric acid, along with impressive pitting and crevice corrosion resistance in environments rich in chlorides. The seamless design of 904L pipes bolsters their structural integrity, ensuring consistent strength and eliminating the risk of leaks or failures in high-pressure or high-temperature applications. Despite their high alloy content, these pipes also boast excellent weldability and formability.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel 904L Seamless Pipes in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 904L | N08904 | 904S13 | – | 1.4539 | X1NiCrMoCuN25-20-5 | 2562 | – |

You’ll find 904L seamless pipes extensively utilized in **chemical and petrochemical plants**, **heat exchangers**, **seawater cooling systems**, and **gas scrubbers**, where corrosion and contamination resistance is paramount. In the **pharmaceutical** and **food processing sectors**, they are prized for their hygienic qualities and ability to endure aggressive cleaning agents. Additionally, these pipes are employed in **power plants** and **desalination facilities**, where prolonged exposure to harsh media is a common challenge. Stainless Steel 904L Seamless Pipes from Bosega offer a robust and dependable solution for a variety of demanding applications.

Stainless Steel 904L Seamless Pipes are widely used in various industries due to their excellent corrosion resistance and durability. They are ideal for chemical applications, especially in the use of aggressive materials such as acids and chlorides. In the oil and gas industry, these pipelines are used for offshore and pipeline applications. In addition, they are used in the marine environment, power generation, and pharmaceutical industry. Their ability to withstand extreme temperatures and pressures makes them suitable for heat exchangers and pressure vessels, making them reliable in complex applications.

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

| 0-100°C | 0-315°C | 0-538°C | at 100°C | at 500°C | |||||

| 904L | 8000 | 200 | 15 | – | – | 13 | – | 500 | 850 |

©2024 Bosega Pipes and Tubes . All Rights Reserved.