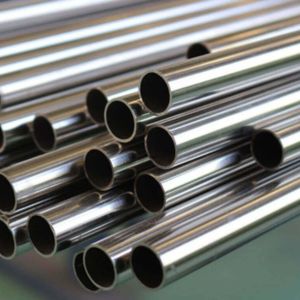

Bosega Pipes and Tubes, located in Cape Town, South Africa, has built a solid reputation as a reliable manufacturer and supplier of high-quality metal tubular products, including Aluminium 1100 Pipes. With a wealth of experience in extrusion and finishing, Bosega produces pipes that offer outstanding corrosion resistance, a lightweight design, and precise dimensions. Catering to various industries like construction, electrical, and general fabrication, the company is committed to maintaining high-quality standards and ensuring dependable supply chains. Thanks to its modern production techniques, Bosega can meet both local and international demands for Aluminium 1100 Pipes, which are celebrated for their purity and versatility.

Aluminium 1100 is a commercially pure alloy (with at least 99% aluminium) that is highly valued for its remarkable corrosion resistance, excellent workability, and superior thermal and electrical conductivity. This soft, ductile material boasts a tensile strength of around 90 MPa and a yield strength close to 35 MPa, with elongation often surpassing 35%. While this alloy cannot be heat-treated, it can be strengthened through cold working. Its softness and outstanding forming properties make it perfect for applications that require easy shaping and welding.

Standards : ASTM B345, B241, B429 / ASME SB345, SB241, SB429

Temper : H14

Standard : AMS QQ-A-200/8, AMS QQ-A-200/9, AMS 4160/4161/4172

Size : 8 (1-1/2″ / 1.900″)

Outer Diameter : 1″ through 16″

Length : Double Random, Single Random, Cut Length

Thickness : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

End : Plain End, Beveled End, Threaded

| Alloy | Fe | Si | Mg | Mn | Cu | Zn | Ti | Cr | Others | AI |

| 1100 (min) | 0.35 | 0.25 | 0.01 | 0.01 | 0.05 | 0.01 | 0.020 | Trace | 0.05 (each) | 99.60% |

| 1100 (max) | 0.50 | 0.35 | 0.03 | 0.05 | 0.20 | 0.05 | 0.030 | Trace | 0.15 (total) | remainder |

| Alloy | Temper | UTS(Mpa) | % Elongation | |||

| Min | Max | 0.5 mm -0.8 mm | 0.81 mm – 1.30 mm | 1.30 mm – above | ||

| 1100 | O | 75 | 110 | 20 | 25 | 29 |

| H12 | 95 | 130 | 5 | 6 | 7 | |

| H14 | 110 | 145 | 3 | 4 | 5 | |

| H16 | 130 | 165 | 2 | 3 | 4 | |

| H18 | 150 | — | 2 | 2 | 3 | |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Aluminium 1100 pipes from Bosega Pipes and Tubes ensures top-quality products tailored to your needs. Our pipes, made from 99.0% pure aluminium, offer exceptional corrosion resistance and conductivity. With a strong commitment to customer satisfaction, we provide competitive pricing and timely delivery, supported by expert guidance from our experienced team. Whether for food processing, chemical handling, or electrical applications, Bosega Pipes and Tubes is your trusted partner for high-performance Aluminium 1100 pipes, ensuring reliability and durability in every project.

Bosega Pipes and Tubes, one of the largest suppliers of Aluminium 1100 pipes in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Aluminium 1100 Pipes to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

| STANDARD | UNS | WERKSTOFF NR. |

| Aluminium 1100 | A91100 | — |

Aluminium 1100 Pipes are frequently utilized in situations that demand exceptional corrosion resistance and good formability. You’ll find them in chemical processing equipment, food and beverage handling, roofing, and ornamental trim. Their excellent conductivity also makes them ideal for electrical and thermal applications. Because of their softness and purity, these pipes are often the go-to choice for decorative and architectural projects, as well as for custom fabrication tasks where ease of shaping is essential.

©2024 Bosega Pipes and Tubes . All Rights Reserved.