Home > Stainless Steel > Stainless Steel 310 and 310S Welded Pipes

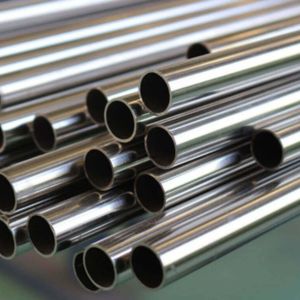

Bosega Pipes and Tubes, located in Cape Town, South Africa, has earned a solid reputation as a reliable manufacturer and supplier of top-notch Stainless Steel 310 and 310S Welded Pipes. These pipes are crafted to excel in high-temperature and corrosive settings. With state-of-the-art manufacturing facilities and a strong commitment to international standards, Bosega Pipes and Tubes guarantees exceptional product reliability, durability, and precision. Their Stainless Steel 310 and 310S Welded Pipes are widely utilized in industries that require strength, heat resistance, and longevity, making them a perfect fit for industrial, structural, and engineering applications.

The composition of Stainless Steel 310 and 310S Welded Pipes includes about 25% chromium and 20% nickel, which gives them outstanding oxidation and corrosion resistance. The low carbon content in 310S improves weldability and reduces carbide precipitation during the welding process. These alloys boast a tensile strength of approximately 515 MPa, a yield strength of 205 MPa, and impressive elongation properties. They maintain excellent mechanical strength even at elevated temperatures, making them ideal for environments that experience thermal cycling and oxidation, ensuring they can handle high mechanical and thermal stress.

Specifications : ASTM A312 / ASME SA312

Outside Diameter : 6.00 mm OD up to 914.4 mm OD, Sizes up to 24″ NB available Ex-stock, OD Size available Ex-stock

Thickness : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Size : 1/2″ NB – 24″ NB

Type : Welded

Form: Round Pipes, Square Pipes, Rectangular Pipes.

Length : Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | – | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | – | X8CrNi25-21 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 310 | >0.015 max | >2.0 max | >0.15 max | >0.020 max | >0.015 max | >24.00 – 26.00 | >0.10 max | >19.00 – 21.00 | >54.7 min |

| SS 310S | 0.08 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 – 26.00 | 0.75 max | 19.00 – 21.00 | 53.095 min |

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| SS 310 and 310S | 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000, MPa – 515 | Psi – 30000, MPa – 205 | 40 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 310 and 310S Welded Pipes guarantees excellent corrosion resistance, high strength, and durability. Designed for diverse industrial applications, it delivers reliable performance in tough environments while maintaining competitive pricing for cost-effective solutions.

Bosega Pipes and Tubes, a leading manufacturer and supplier of Stainless Steel 310 and 310S Welded Pipes in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubing suitable for various industrial applications. Our extensive inventory and commitment to exceptional service make us a trusted choice for regional products.

| NB Sizes | Sch 5 | Sch 10 | Sch 40 | Sch 80 | Sch 160 |

| 1/8″ | ✓ | ✓ | ✓ | ✓ | |

| 1/4″ | ✓ | ✓ | ✓ | ✓ | |

| 3/8″ | ✓ | ✓ | ✓ | ✓ | |

| 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 3/4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1 1/4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 2 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 3″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 5″ | ✓ | ✓ | ✓ | ✓ | |

| 6″ | ✓ | ✓ | ✓ | ✓ |

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

| 0-1000C | 0-3150C | 0-5380C | at 1000C | at 5000C | |||||

| 310 and 310S | 7750 | 200 | 15.9 | 16.2 | 17.0 | 14.2 | 18.7 | 500 | 720 |

We offer custom sizes for Stainless Steel 310 and 310S Welded Pipes to meet your specific needs. Our dedicated team at Bosega Pipes and Tubes provides tailored solutions for all your piping and tubing requirements. For more information, contact us at sales@bosegapipes.co.za.

Stainless Steel 310 and 310S Welded Pipes find extensive use in high-temperature applications like furnaces, heat exchangers, kilns, and power plants. Their remarkable resistance to oxidation, carburization, and sulfidation makes them perfect for the petrochemical, refinery, and thermal processing sectors. These pipes are also used in steam boilers, exhaust manifolds, and food processing equipment, where both strength and heat resistance are essential. Thanks to their outstanding formability and durability, they are well-suited for both structural and pressure-bearing applications in demanding industrial environments.

©2024 Bosega Pipes and Tubes . All Rights Reserved.