Home > Stainless Steel > Stainless Steel 904L Welded Pipes

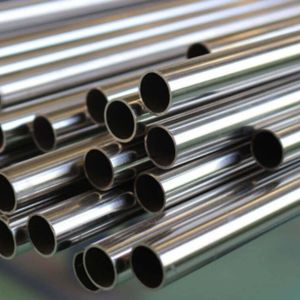

Bosega Pipes and Tubes, based in Cape Town, South Africa, stands out as a trusted manufacturer and supplier of premium **Stainless Steel 904L Welded Pipes**. These pipes are specifically engineered for use in highly corrosive settings where maintaining structural integrity and resisting chemical attacks are crucial. Crafted to meet international standards, Bosega’s 904L welded pipes find their applications across various industries, including chemical processing, marine operations, pulp and paper production, and pollution control systems, ensuring reliable performance and longevity.

Stainless Steel 904L Welded Pipes are made from a high-nickel-molybdenum alloy with approximately 19% nickel, 24% chromium and 4.5% molybdenum This material enhances corrosion resistance, especially against pitting and crevice corrosion in acidic environments. Mechanical properties include high tensile strength (up to 620 MPa) and good ductility. The advantages of 904L welded pipes include excellent resistance to chloride stress corrosion cracking, suitability for high temperature applications, and resistance to harsh environmental conditions, making them ideal for chemical processing, oil and gas, and marine applications.

Specifications : ASTM A312 / ASME SA312

Outside Diameter : 6.00 mm OD up to 914.4 mm OD, Sizes up to 24″ NB available Ex-stock, OD Size available Ex-stock

Thickness : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Size : 1/2″ NB – 24″ NB

Type : Welded

Form: Round Pipes, Square Pipes, Rectangular Pipes.

Length : Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | KS |

| SS 904L | N08904 | 1.4539 | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 | SUS 904L | 904S13 | STS 317J5L |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

| SS 904L | 0.020 max | 2.00 max | 1.00 max | 0.040 max | 0.030 max | 19.00 – 23.00 | 4.00 – 5.00 max | 23.00 – 28.00 | 1.00 – 2.00 |

| Grade | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| SS 904L | Psi – 71000, MPa – 490 | Psi – 32000, MPa – 220 | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

**Stainless Steel 904L** is a super austenitic stainless steel alloy, rich in chromium, nickel, molybdenum, and copper, which grants it exceptional resistance to harsh acids like sulfuric, phosphoric, and acetic acid. The welded pipes are created from rolled stainless steel sheets that are expertly joined using advanced welding techniques, followed by comprehensive post-weld treatments to restore corrosion resistance at the weld area. These pipes excel in resisting pitting, crevice corrosion, and stress corrosion cracking, particularly in environments with chloride exposure.

Bosega Pipes and Tubes, a leading manufacturer and supplier of Stainless Steel 904L Welded Pipes in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubing suitable for various industrial applications. Our extensive inventory and commitment to exceptional service make us a trusted choice for regional products.

| NB Sizes | Sch 5 | Sch 10 | Sch 40 | Sch 80 | Sch 160 |

| 1/8″ | ✓ | ✓ | ✓ | ✓ | |

| 1/4″ | ✓ | ✓ | ✓ | ✓ | |

| 3/8″ | ✓ | ✓ | ✓ | ✓ | |

| 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 3/4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1 1/4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 2 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 3″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 5″ | ✓ | ✓ | ✓ | ✓ | |

| 6″ | ✓ | ✓ | ✓ | ✓ |

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Co-eff of Thermal Expansion (µm/m/°C) | Thermal Conductivity (W/m.K) | Specific Heat 0-100°C (J/kg.K) | Elec Resistivity (nΩ.m) | |||

| 0-100°C | 0-315°C | 0-538°C | At 20°C | At 500°C | |||||

| 904L | 7900 | 190 | 15 | – | – | 11.5 | – | 500 | 952 |

You’ll find 904L welded pipes commonly utilized in **chemical and fertilizer production**, **seawater cooling systems**, **acid processing plants**, and **oil refinery equipment**, where aggressive substances and high temperatures are the norm. Their outstanding weldability, along with cost-effective fabrication for larger diameters, makes them a go-to choice for high-volume industrial piping systems. In **pharmaceutical** and **food processing settings**, their hygienic features and corrosion resistance ensure they meet stringent safety and cleanliness standards. With Bosega’s Stainless Steel 904L Welded Pipes, you’re guaranteed a durable, efficient, and corrosion-resistant solution.

Stainless Steel 904L Welded Pipes are widely used in various industries due to their exceptional corrosion resistance and durability. Common uses include the chemical industry, where strong chemicals and acids are transported. Because of their resilience, they are also used in oil and gas production, medicine and the marine environment. Moreover, these pipes are used in heat exchangers, pressure vessels and fouling control devices. Their versatility makes them desirable for critical applications requiring reliability and durability in harsh environments.

©2024 Bosega Pipes and Tubes . All Rights Reserved.