Home > Stainless Steel > Stainless Steel 316Ti Welded Pipes

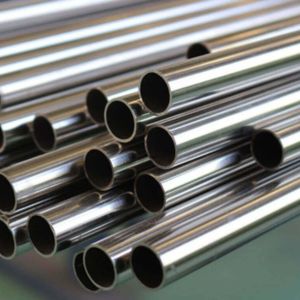

Bosega Pipes and Tubes, located in Cape Town, South Africa, stands out as a top manufacturer and supplier of Stainless Steel 316Ti Welded Pipes. They provide dependable solutions for industries that need high corrosion resistance and reliable performance in high-temperature settings. These welded pipes are crafted to meet international standards, guaranteeing consistent quality, strength, and weld integrity. With a keen focus on the specific needs of their customers and rigorous quality control, Bosega delivers 316Ti welded pipes to various sectors, including chemical processing, marine engineering, pharmaceutical manufacturing, and food processing.

Stainless Steel 316Ti is a titanium-stabilized variant of 316 stainless steel, enriched with molybdenum for enhanced corrosion resistance and titanium to prevent sensitization during welding or extended exposure to high temperatures. This stabilization enables 316Ti to fend off intergranular corrosion and maintain its structural integrity in high-temperature applications, particularly within the 500–850°C (932–1562°F) range. The welded form is perfect for large-scale piping systems and structural applications, providing excellent strength, good formability, and durability under pressure and thermal stress. Additionally, it is non-magnetic in its annealed state and boasts impressive mechanical and oxidation-resistant properties.

Specifications : ASTM A312 / ASME SA312

Outside Diameter : 6.00 mm OD up to 914.4 mm OD, Sizes up to 24″ NB available Ex-stock, OD Size available Ex-stock

Thickness : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Size : 1/2″ NB – 24″ NB

Type : Welded

Form: Round Pipes, Square Pipes, Rectangular Pipes.

Length : Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

| STANDARD | WERKSTOFF NR. | UNS | JIS | AFNOR | BS | GOST | EN |

| SS 316Ti | 1.4571 | S31635 | SUS 316Ti | Z6CNDT17‐12 | 320S31 | 08Ch17N13M2T | X6CrNiMoTi17-12-2 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 316Ti | Min | – | – | – | – | – | 16.0 | 2.00 | 10.0 | – |

| max | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.1 |

| Grade | Tensile Strength (MPa) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (MPa) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 316Ti | 515 | 35 | 205 | 75 | 205 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 316Ti Welded Pipes guarantees excellent corrosion resistance, high strength, and durability. Designed for diverse industrial applications, it delivers reliable performance in tough environments while maintaining competitive pricing for cost-effective solutions.

Stainless Steel 316Ti Welded Pipes find their place in heat exchangers, pressure vessels, exhaust manifolds, flue gas systems, and pipelines that handle hot, corrosive fluids. Their ability to resist chloride-induced corrosion and withstand elevated temperatures makes them ideal for marine, offshore, and chemical plant environments. The welded design is both cost-effective and reliable for large-diameter pipes, especially in systems where seamless tubing isn’t necessary. With outstanding weldability and longevity, these pipes are a smart choice for demanding applications.

| NB Sizes | Sch 5 | Sch 10 | Sch 40 | Sch 80 | Sch 160 |

| 1/8″ | ✓ | ✓ | ✓ | ✓ | |

| 1/4″ | ✓ | ✓ | ✓ | ✓ | |

| 3/8″ | ✓ | ✓ | ✓ | ✓ | |

| 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 3/4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1 1/4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 2 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 3″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 5″ | ✓ | ✓ | ✓ | ✓ | |

| 6″ | ✓ | ✓ | ✓ | ✓ |

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

| 0-1000C | 0-3150C | 0-5380C | at 1000C | at 5000C | |||||

| 316Ti | 8000 | 193 | 17.2 | 17.8 | 18.4 | 16.2 | 21.5 | 500 | 720 |

We offer custom sizes for Stainless Steel 316Ti Welded Pipes to meet your specific needs. Our dedicated team at Bosega Pipes and Tubes provides tailored solutions for all your piping and tubing requirements. For more information, contact us at sales@bosegapipes.co.za.

Stainless Steel 316Ti Welded Pipes are widely used in various industries due to their corrosion resistance and high temperature. Typical applications are in the chemical industry, oil and gas exploration, and the marine environment, where exposure to extreme conditions is common. These pipes are also used in the food and pharmaceutical industries due to their purity. In addition, they are suitable for electricity and wastewater treatment. Their rugged construction and versatility make 316Ti welded pipes ideal for applications requiring reliable and durable performance in harsh environments.

©2024 Bosega Pipes and Tubes . All Rights Reserved.