Home > Stainless Steel > Stainless Steel 316 and 316L Welded Pipes

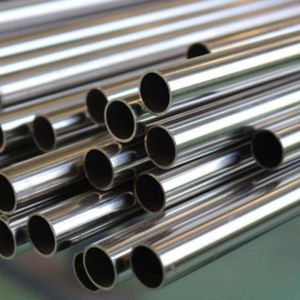

Bosega Pipes and Tubes stands out as a top-notch manufacturer and supplier of Stainless Steel 316 and 316L Welded Pipes right in Cape Town, South Africa. They offer high-quality piping solutions that are built to resist corrosion, ensure durability, and deliver reliable performance. The Stainless Steel 316 and 316L grades are austenitic, featuring a higher molybdenum content that gives them remarkable resistance to pitting, crevice corrosion, and harsh oxidizing environments. Bosega takes pride in their precision welding, smooth finishes, and consistent wall thickness, ensuring their pipes meet international standards and perform dependably in various sectors, including chemical, petrochemical, marine, and industrial applications.

When it comes to composition, Stainless Steel 316 Welded Pipes are made up of iron, chromium (16–18%), nickel (10–14%), molybdenum (2–3%), along with trace amounts of carbon, manganese, and silicon. On the other hand, Stainless Steel 316L has a lower carbon content (≤0.03%), which enhances its weldability and minimizes the risk of intergranular corrosion post-welding. Both grades boast impressive mechanical properties, including high tensile and yield strength, excellent toughness, and good ductility. Their austenitic microstructure guarantees dimensional stability, resistance to stress corrosion, and reliable performance even under fluctuating pressure and temperature conditions.

Specifications : ASTM A312 / ASME SA312

Outside Diameter : 6.00 mm OD up to 914.4 mm OD, Sizes up to 24″ NB available Ex-stock, OD Size available Ex-stock

Thickness : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Size : 1/2″ NB – 24″ NB

Type : Welded

Form: Round Pipes, Square Pipes, Rectangular Pipes.

Length : Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 316 | S31600 | 316S31 | 58H, 58J | 1.4401 | X5CrNiMo17-12-2 | 2347 | SUS 316 |

| 316L | S31603 | 316S11 | – | 1.4404 | X2CrNiMo17-12-2 | 2348 | SUS 316L |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 316 | min. max. | – 0.08 | – 2.0 | – 0.75 | – 0.045 | – 0.03 | 16.0 18.0 | 2.00 3.00 | 10.0 14.0 | – 0.10 |

| 316L | min. max. | – 0.03 | – 2.0 | – 0.75 | – 0.045 | – 0.03 | 16.0 18.0 | 2.00 3.00 | 10.0 14.0 | – 0.10 |

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 316 | 515 | 205 | 40 | 95 | 217 |

| 316L | 485 | 170 | 40 | 95 | 217 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 316 and 316L Welded Pipes guarantees excellent corrosion resistance, high strength, and durability. Designed for diverse industrial applications, it delivers reliable performance in tough environments while maintaining competitive pricing for cost-effective solutions.

Bosega Pipes and Tubes, a leading manufacturer and supplier of Stainless Steel 316 and 316L Welded Pipes in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubing suitable for various industrial applications. Our extensive inventory and commitment to exceptional service make us a trusted choice for regional products.

| NB Sizes | Sch 5 | Sch 10 | Sch 40 | Sch 80 | Sch 160 |

| 1/8″ | ✓ | ✓ | ✓ | ✓ | |

| 1/4″ | ✓ | ✓ | ✓ | ✓ | |

| 3/8″ | ✓ | ✓ | ✓ | ✓ | |

| 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 3/4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1 1/4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 2 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 3″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 5″ | ✓ | ✓ | ✓ | ✓ | |

| 6″ | ✓ | ✓ | ✓ | ✓ |

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

| 0-1000C | 0-3150C | 0-5380C | at 1000C | at 5000C | |||||

| 316 – 316L | 8000 | 193 | 15.9 | 16.2 | 17.5 | 16.3 | 21.5 | 500 | 74 |

We offer custom sizes for Stainless Steel 316 and 316L Welded Pipes to meet your specific needs. Our dedicated team at Bosega Pipes and Tubes provides tailored solutions for all your piping and tubing requirements. For more information, contact us at sales@bosegapipes.co.za.

These Stainless Steel 316 and 316L Welded Pipes find extensive use in chemical and petrochemical plants, marine and offshore systems, as well as in the pharmaceutical and food processing industries, where corrosion resistance and durability are crucial. They are perfect for applications like heat exchangers, process piping, storage tanks, and pressure vessels. Additionally, they are utilized in seawater systems, desalination plants, and industrial fluid transport, providing long-lasting, low-maintenance, and high-performance piping solutions for even the most aggressive and demanding environments.

©2024 Bosega Pipes and Tubes . All Rights Reserved.