Home > Stainless Steel > Stainless Steel 347 and 347H Welded Pipes

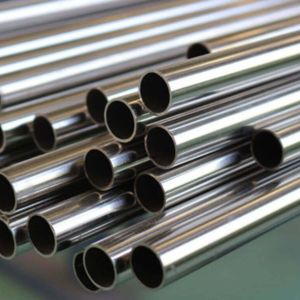

Bosega Pipes and Tubes, located in Cape Town, South Africa, proudly offers top-notch **Stainless Steel 347 and 347H Welded Pipes**, designed for exceptional performance in high-temperature and corrosive environments. These niobium-stabilized austenitic stainless steels are specifically engineered to resist intergranular corrosion and maintain their structural integrity even under prolonged heat exposure. At Bosega, we manufacture our welded pipes to adhere to rigorous international standards, ensuring consistent quality, precise dimensions, and durability for critical industrial applications.

Stainless Steel 347 and 347H Welded Pipes are characterized by their structure, which contains significant amounts of chromium, nickel, and columbium, which increases their intergranular corrosion resistance and mechanical properties have high tensile strength, with 347H providing strength a higher elevation. Both grades exhibit excellent rigidity and flexibility, making them suitable for challenging environments. Advantages include excellent oxidation resistance, ease of manufacture and durability, making it ideal for applications in the chemical industry, the petrochemical industry and in high-temperature environments where stability is required.

Specifications : ASTM A312 / ASME SA312

Outside Diameter : 6.00 mm OD up to 914.4 mm OD, Sizes up to 24″ NB available Ex-stock, OD Size available Ex-stock

Thickness : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Size : 1/2″ NB – 24″ NB

Type : Welded

Form: Round Pipes, Square Pipes, Rectangular Pipes.

Length : Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

| STANDARD | WERKSTOFF NR. | UNS | JIS | GOST | EN |

| SS 347 | 1.4550 | S34700 | SUS 347 | 08Ch18N12B | X6CrNiNb18-10 |

| SS 347H | 1.4961 | S34709 | SUS 347H | – | X6CrNiNb18-12 |

| Grade | C | Mn | Si | P | S | Cr | Cb | Ni | Fe |

| SS 347 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 20.00 | 10xC – 1.10 | 9.00 – 13.00 | 62.74 min |

| SS 347H | 0.04 – 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 8xC – 1.10 | 9.0 -13.0 | 63.72 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000, MPa – 515 | Psi – 30000, MPa – 205 | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

**Stainless Steel 347** is stabilized with niobium (columbium), which effectively prevents carbide precipitation during welding and high-temperature exposure, making it a fantastic choice for applications that experience frequent thermal cycling. On the other hand, **347H** is the high-carbon variant of 347, providing enhanced creep strength and better resistance to long-term heat exposure. Our welded pipes are created by expertly joining stainless steel plates or coils through precision welding techniques, offering a cost-effective solution for large-diameter, low-to-medium pressure piping systems that boast excellent corrosion resistance and mechanical strength.

Bosega Pipes and Tubes, a leading manufacturer and supplier of Stainless Steel 347 and 347H Welded Pipes in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubing suitable for various industrial applications. Our extensive inventory and commitment to exceptional service make us a trusted choice for regional products.

| NB Sizes | Sch 5 | Sch 10 | Sch 40 | Sch 80 | Sch 160 |

| 1/8″ | ✓ | ✓ | ✓ | ✓ | |

| 1/4″ | ✓ | ✓ | ✓ | ✓ | |

| 3/8″ | ✓ | ✓ | ✓ | ✓ | |

| 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 3/4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1 1/4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 2 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 3″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 5″ | ✓ | ✓ | ✓ | ✓ | |

| 6″ | ✓ | ✓ | ✓ | ✓ |

These pipes find extensive use in **petrochemical plants**, **refineries**, **power generation facilities**, **heat exchangers**, and **aircraft exhaust systems**, where dependable performance under high temperatures and corrosive conditions is essential. Their outstanding weldability and resistance to oxidation and stress corrosion cracking make them perfect for structural and fluid handling applications in challenging environments. With Stainless Steel 347 and 347H Welded Pipes from Bosega, you get long-lasting, efficient solutions for industries that require both high-temperature strength and corrosion resistance.

Stainless Steel 347 and 347H Welded Pipes are widely used in various industries due to their excellent corrosion resistance and mechanical properties The most common applications are the chemical and petrochemical industries, where they are used in mechanical applications processing, heat exchangers and piping systems. It is used in power plants and aerospace applications, where resistance to high temperatures is required. Moreover, these pipelines are suitable for food processing and pharmaceutical industry due to their purity. Its versatility and durability make it ideal for harsh environments and applications.

©2024 Bosega Pipes and Tubes . All Rights Reserved.