Home > Stainless Steel > Stainless Steel 310H Electropolished Pipes

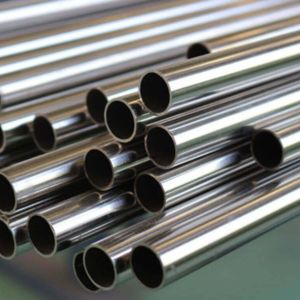

Bosega Pipes and Tubes is a well-respected manufacturer and supplier located in Cape Town, South Africa, specializing in top-notch Stainless Steel 310H Electropolished Pipes. These pipes are crafted for outstanding performance in high-temperature and corrosive settings, utilizing cutting-edge technology and precision engineering. Bosega takes pride in delivering exceptional surface finishes, precise dimensions, and remarkable durability, all thanks to their rigorous quality control processes. Their 310H electropolished pipes are highly sought after in various industries, including petrochemical, power generation, and food processing, where cleanliness, strength, and resistance to oxidation and corrosion are essential for dependable and efficient operations.

Stainless Steel 310H Electropolished Pipes are made from an austenitic stainless steel alloy that contains 24–26% chromium and 19–22% nickel, providing excellent resistance to oxidation and corrosion. The increased carbon content in the 310H grade boosts its high-temperature strength and creep resistance. These pipes boast a tensile strength of about 515 MPa, a yield strength of around 205 MPa, and an elongation of 40%. With remarkable mechanical stability, toughness, and durability, the electropolished surface enhances both corrosion resistance and cleanliness, making them perfect for challenging thermal and chemical environments.

| Specifications | : | ASTM A/ASME SA249/A269/A270 |

| Dimensions | : | ASTM, ASME, and API |

| SS 310H Pipes Size | : | 1/8″NB TO 30″NB IN |

| Thickness | : | 1mm to 20mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10 |

| Finish | : | BA Finish inside and outside, Electropolished finish inside and outside |

| Type | : | Electropolished Pipes & Tubes |

| Form | : | Round, Square, Rectangular, Hydraulic Etc |

| Length | : | Up to 6 meters, custom cut lengths |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 310H | min. | 0.04 | – | – | – | – | 24.0 | – | 19.0 | – |

| max. | 0.10 | 2.0 | 1.00 | 0.045 | 0.030 | 26.0 | 21.0 | – | ||

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 310H | 515 | 205 | 40 | 95 | 217 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 310H Electropolished Pipes from Bosega Pipes and Tubes ensures high quality and durability, as these pipes offer excellent corrosion resistance and strength. Our commitment to exceptional service and reliable delivery guarantees customer satisfaction across various industrial applications. Our expertise in stainless steel products ensures you receive a top-tier solution tailored to your needs.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel 310H Electropolished Pipes in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 310H | S31009 | – | – | – | – | – | – |

Yes, we offer custom sizes for Stainless Steel 310H Electropolished Pipes to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

These Stainless Steel 310H Electropolished Pipes find extensive use in industries that demand high corrosion resistance, superior surface quality, and thermal stability. Typical applications include heat exchangers, chemical reactors, furnace tubes, food processing systems, and power generation equipment. The electropolished surface helps reduce contamination, boosts flow efficiency, and improves resistance to scaling and oxidation at high temperatures. They are particularly well-suited for hygienic and high-purity applications in pharmaceutical and chemical facilities. Their outstanding mechanical strength and smooth internal finish guarantee reliable, long-lasting performance in critical processes and heat applications.

©2024 Bosega Pipes and Tubes . All Rights Reserved.