Home > Stainless Steel > Stainless Steel 317 and 317L Electropolished Pipes

Bosega Pipes and Tubes, located in Cape Town, South Africa, stands out as a reliable manufacturer and supplier of Stainless Steel 317 and 317L Electropolished Pipes. They provide top-notch piping solutions tailored for industries that demand ultra-clean surfaces and exceptional corrosion resistance. The electropolishing process plays a crucial role in enhancing the surface finish by eliminating tiny imperfections, leading to smoother internal surfaces that minimize product buildup and optimize fluid flow. These pipes find their place in critical applications across the pharmaceutical, biotechnology, food processing, chemical, and high-purity water systems, where cleanliness, hygiene, and corrosion resistance are non-negotiable.

Stainless Steel 317 is a high-alloy austenitic stainless steel, enriched with molybdenum to offer outstanding resistance to pitting and crevice corrosion. Its low-carbon variant, 317L, is specifically engineered to combat intergranular corrosion during welding and high-temperature operations, making it perfect for systems that require both structural integrity and ease of cleaning. Electropolished 317/317L pipes not only boast excellent mechanical strength but also feature enhanced surface passivation and a lower risk of contamination. The electropolished finish improves the chromium-to-iron ratio at the surface, further boosting resistance to chemical attacks, particularly in environments rich in chlorides and acids.

| Specifications | : | ASTM A/ASME SA249/A269/A270 |

| Dimensions | : | ASTM, ASME, and API |

| SS 317 and 317L Pipes Size | : | 1/8″NB TO 30″NB IN |

| Thickness | : | 1mm to 20mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10 |

| Finish | : | BA Finish inside and outside, Electropolished finish inside and outside |

| Type | : | Electropolished Pipes & Tubes |

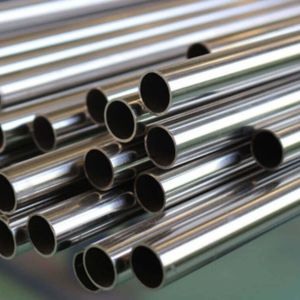

| Form | : | Round, Square, Rectangular, Hydraulic Etc |

| Length | : | Up to 6 meters, custom cut lengths |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.845 min |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 317 and 317L Electropolished Pipes from Bosega Pipes and Tubes guarantees excellent corrosion resistance, high strength, and durability. Designed for diverse industrial applications, it delivers reliable performance in tough environments while maintaining competitive pricing for cost-effective solutions.

Stainless Steel 317 and 317L Electropolished Pipes are essential for ultra-pure fluid handling, process piping, and high-end sanitary systems where corrosion resistance and internal surface quality are paramount. These pipes excel in applications like purified water lines, clean steam systems, chemical injection lines, and sterile production facilities. Their smooth internal surfaces help reduce turbulence and prevent bacterial growth, ensuring optimal performance in sensitive environments.

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 317 | 1.4449 | S31700 | SUS 317 | – |

| SS 317L | 1.4438 | S31703 | SUS 317L | X2CrNiMo18-15-4 |

We offer custom sizes for Stainless Steel 317 and 317L Electropolished Pipes to meet your specific needs. Our dedicated team at Bosega Pipes and Tubes provides tailored solutions for all your piping and tubing requirements. For more information, contact us at sales@bosegapipes.co.za.

Stainless Steel 317 and 317L Electropolished Pipes are widely used in various industries due to their corrosion resistance and durability They are commonly used in chemical, petrochemical, oil and gas applications, where they are exposed to areas a it’s hard to. In addition, these pipelines are excellent in the pharmaceutical and food industries, ensuring the delivery of clean water. Their smooth electroplated surfaces reduce dirt and make cleaning easier. Other applications include the marine environment, pulp and paper manufacturing, and any situation that requires the use of robust and efficient pipelines.

©2024 Bosega Pipes and Tubes . All Rights Reserved.