Home > Stainless Steel > Stainless Steel Instrumentation Tubing

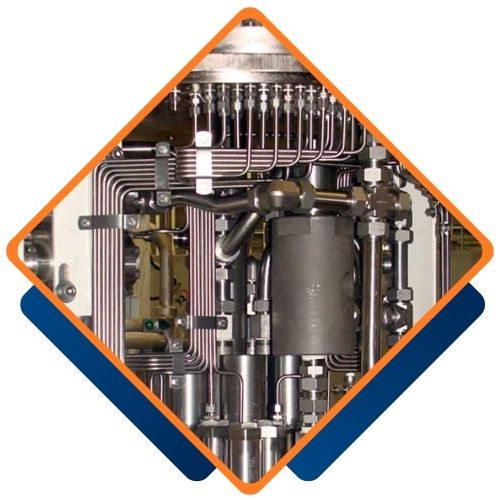

Bosega Pipes and Tubes, based in Cape Town, South Africa, stands out as a top supplier of precision-engineered **Stainless Steel Instrumentation Tubing**. This tubing is crafted to meet the stringent demands of instrumentation and control systems, providing exceptional corrosion resistance, durability, and precise dimensional accuracy. Bosega guarantees that their instrumentation tubing complies with international quality standards, making it a go-to choice for industries like oil and gas, petrochemical, power generation, and pharmaceuticals, where reliable and accurate flow measurement and control are essential.

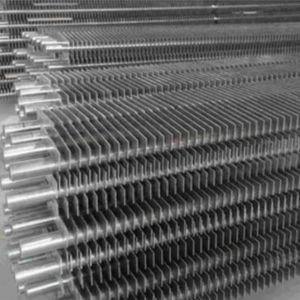

Stainless steel instrumentation tubing is mainly composed of iron, chromium (10-30%), nickel, and molybdenum, which increases its corrosion resistance and mechanical strength Its mechanical characteristics include high tensile strength (approximately 500-800). MPa) and yield strength (up to 300 MPa), which makes it very stable under tension. The tubing exhibits outstanding flexibility, making it easy to install in complex systems. Advantages include resistance to corrosion, extreme temperatures and exceptional pressures, making it ideal for use in the oil and gas, chemical processing and pharmaceutical industries Its cleanliness and non-allergenic properties ensures safe circulation of water during critical applications.

| Marking | All Stainless Steel Instrumentation tubes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

|---|---|

| Stainless Steel Instrumentation Tube Size | 3.35 mm OD To 101.6 mm OD |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| SS Instrumentation tube Length | Single Random, Double Random, Standard & Cut length |

| Stainless Steel Instrumentation Tube Type | Seamless, ERW, EFW, Welded, Fabricated |

| Stainless Steel Instrumentation Tube Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

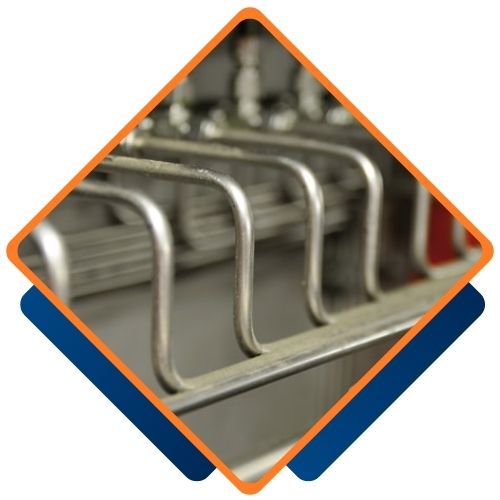

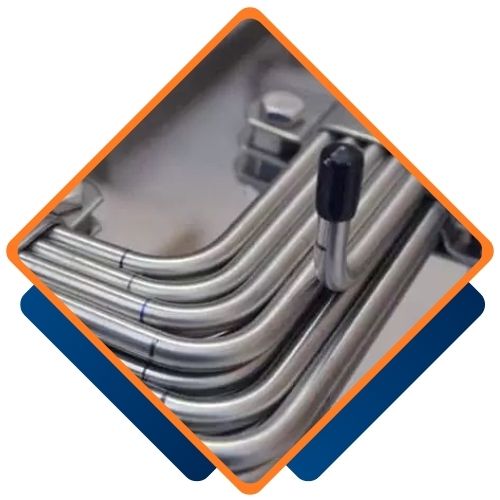

| Stainless Steel Instrumentation tube Form | Round, Coil, Square, Rectangular, Boiler, Hydraulic, Straight or ‘U’ bent Tubes, Hollow, LSAW Tubes Etc. |

| Stainless Steel Welded Tube Size | 6.35 mm OD To 152 mm OD |

| End | Plain End, Beveled End, Treaded |

| Specialize in | Stainless Steel Instrumentation Capillary Tube & Other Odd Size Stainless Steel Heat Exchanger & Condenser Tubes |

| Application | Oil Tube, Gas Tube, Fluid Tube, Boiler and Heatexchanger |

| Stainless Steel Tube Standards | ASTM B/ASME SB674 / SB677 |

| Test Certificate | Manufacturer Test Certificate Laboratory Test Certificate from Govt. Approved Lab. Under Third Party Inspection |

| Stainless Steel Instrumentation tubing wall thickness | 0.020″ –0.220″, (special wall thicknesses available) |

| Material | C | Mn | Si | P | S | Cr | MO | Ni | Cu | |

| SS | min. | – | – | – | – | – | 19.0 | 4.0-5.0 | 23.0 | 1.0 |

| max. | 0.20 | 2.0 | 1.0 | 0.045 | 0.035 | 23.0 | 28.0 | 2.0 | ||

| Material | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| SS | 490 | 220 | 35 | 70-90 typical | – |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Typically made from grades such as 304, 316, and 316L stainless steel, **Stainless Steel Instrumentation Tubing** boasts excellent resistance to oxidation, corrosion, and high temperatures. Its seamless design ensures a smooth internal surface, which is crucial for accurate pressure transmission and reducing flow disturbances. The tubing comes in a variety of sizes and wall thicknesses to meet different system needs, and it can be easily bent or shaped without sacrificing its structural integrity or performance.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel Instrumentation Tubing in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

This type of tubing is widely utilized in instrumentation and control lines, hydraulic systems, and pneumatic systems where precise pressure and flow control are vital. Common applications include pressure gauges, transmitters, valves, and analyzers across sectors such as oil and gas, chemical processing, power plants, and manufacturing. The combination of strength, corrosion resistance, and accuracy in Stainless Steel Instrumentation Tubing makes it essential for critical monitoring and control tasks in challenging and demanding environments.

Stainless steel instrumentation tubing is essential for reliability and durability in a variety of applications. It is widely used in the oil and gas industry for pressure monitoring and monitoring systems. To ensure accurate readings in harsh environments. It facilitates the delivery of liquids and gases in medicine maintaining safety and integrity. Chemists use it to transport hygienic products that adhere to strict hygiene standards. In addition they are used in the food and beverage industry for sanitary applications and for aerospace applications for fuel pipelines and water systems, where efficiency and safety are required.

©2024 Bosega Pipes and Tubes . All Rights Reserved.