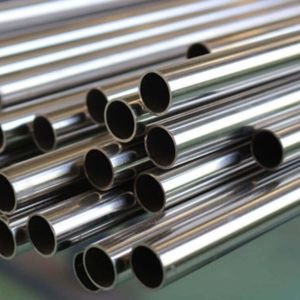

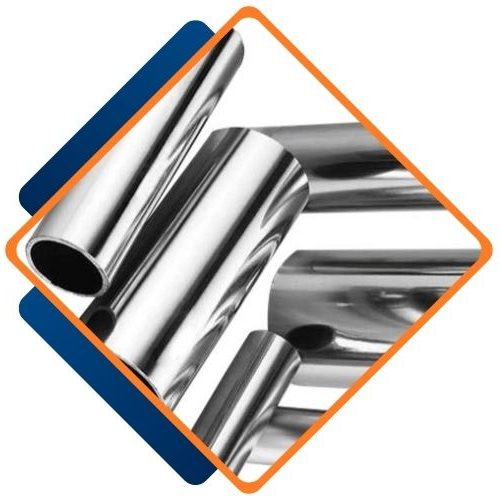

Bosega Pipes and Tubes, located in Cape Town, South Africa, stands out as a top manufacturer and supplier of high-quality Aluminium Welded Tubing. Renowned for its impressive strength-to-weight ratio, resistance to corrosion, and versatility, Bosega’s aluminium welded tubing is designed to cater to the varied needs of industries like automotive, aerospace, construction, and furniture manufacturing. With a focus on precise welding techniques and strict quality controls, Bosega guarantees that its tubing offers consistent dimensional accuracy, durability, and meets international standards.

The process of creating aluminium welded tubing involves shaping aluminium sheets or strips into a tubular form and joining the edges using advanced welding techniques such as TIG or laser welding. This method produces strong, lightweight tubes with smooth finishes and tight tolerances. Commonly used aluminium alloys include 6061 and 6063, which provide excellent mechanical properties, corrosion resistance, and weldability.

Standards : ASTM B345, B241, B429 / ASME SB345, SB241, SB429

Temper : T6 T651 T6511

Standard : AMS QQ-A-200/8, AMS QQ-A-200/9, AMS 4160/4161/4172

Size : 8 (1-1/2″ / 1.900″)

Outer Diameter : 1″ through 16″

Length : Double Random, Single Random, Cut Length

Thickness : SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

End : Plain End, Beveled End, Threaded

| Alloy | Fe | Si | Mg | Mn | Cu | Zn | Ti | Cr | Others | AI |

| 1100 (min) | 0.35 | 0.25 | 0.01 | 0.01 | 0.05 | 0.01 | 0.020 | Trace | 0.05 (each) | 99.60% |

| 1100 (max) | 0.50 | 0.35 | 0.03 | 0.05 | 0.20 | 0.05 | 0.030 | Trace | 0.15 (total) | remainder |

| 5083 | 0.40 max | 0.40 max | 4.0 / 4.90 | 0.40 / 1.0 | 0.10 max | 0.25 max | 0.15 max | 0.05 / 0.25 | 0.05 max | Bal |

| 6061 | 0.7 | 0.4-0.8 | 0.8-1.2 | 0.15 | 0.15-0.4 | 0.25 | 0.15 | 0.15-0.35 | 0.005/0.15 | Remainder |

| 6068 | 0.50 max | 0.7 – 1.3 | 0.06-1.20 | 0.40-1.00 | 0.10 max | 0.20 max | 0.10 max | 0.25 max | 0.05 max | Bal |

| 7075 min | 2.10 | 1.20 | 5.10 | 0.18 | ||||||

| 7075 max | 0.50 | 0.40 | 2.90 | 0.30 | 2.00 | 6.10 | 0.20 | 0.28 | 0.05 |

| Alloy | Temper | UTS(Mpa) | % Elongation | Tensile Strength | Hardness Brinell | Proof Stress | Yield Strength (PSI) | Shear Strength (PSI) | Brinell Hardness | |||

| Min | Max | 0.5 mm -0.8 mm | 0.81 mm – 1.30 mm | 1.30 mm – above | ||||||||

| 1100 | O | 75 | 110 | 20 | 25 | 29 | ||||||

| H12 | 95 | 130 | 5 | 6 | 7 | |||||||

| H14 | 110 | 145 | 3 | 4 | 5 | |||||||

| H16 | 130 | 165 | 2 | 3 | 4 | |||||||

| H18 | 150 | — | 2 | 2 | 3 | |||||||

| 5083 | 12 Min % | 275 – 350 MPa | 75 HB | 125 Min MPa | ||||||||

| 6061 | – | 45,000 | 12 | 40,000 | 31,000 | 95 | ||||||

| 6082 | 8 | 295 | 95 | – | 240 | – | – | |||||

| 7075 T6, T651 | 11 | 83-572 | 73- 503 | 150 | ||||||||

| 7075 T73, T7351 | 13 | 73-503 | 63-434 | NA | ||||||||

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Aluminium Welded Tubing from Bosega Pipes and Tubes ensures you receive top-quality products tailored to your specific requirements. Our tubing is manufactured using advanced techniques and high-grade aluminum alloys, providing exceptional strength and durability. We adhere to stringent quality control standards to guarantee reliability and performance in various applications, including automotive, aerospace, and construction. With a commitment to customer satisfaction, we offer customized solutions, timely delivery, and expert support, making Bosega Pipes and Tubes your trusted partner for all your aluminium welded tubing needs.

Bosega Pipes and Tubes, one of the largest suppliers of Aluminium Welded Tubing in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Aluminium Welded Tubing to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

| Grade | UNS | USA | Japan | France | ISO | WNR | EN | DIN | ISO | BS (OLD) |

| 1100 | A91100 | AA1100 | JIS A1100P | NF 1100 | Al 99.0 Cu. | – | – | – | – | – |

| 6082 | A96082 | AA6082 | – | – | – | 3.2315 | AW-6082 | AlMgSi1 | AlSi1MgMn | HE30 |

| 5083 | A95083 | 5083 | – | – | AlMg4,5Mn0,7 | 3.3547 | AW-AlMg4,5Mn0,7 | AlMg4,5Mn | – | – |

| 6061 | A96061 | AA6061 | – | – | – | 3.3211 | AW-AlMg1SiCu EN AW-6061 | AlMgSiCu | AlMg1SiCu | HE20 |

| 7075 | A97075 | 7075 | 3.4365 | ENAW-AlZn5.5MgCu EN AW-7075 | AlZnMgCu1.5 | AlZn6MgCu | 7075 L95 L96, V95 |

Aluminium welded tubing finds extensive use in structural applications, architectural frameworks, transportation, and fluid handling systems. Its unique combination of light weight, strength, and corrosion resistance makes it perfect for applications that demand energy efficiency and a long service life, while its ease of fabrication ensures cost-effective manufacturing.

©2024 Bosega Pipes and Tubes . All Rights Reserved.