Home > Alloy Steel> ASTM A335 Gr P91 Seamless Pipe

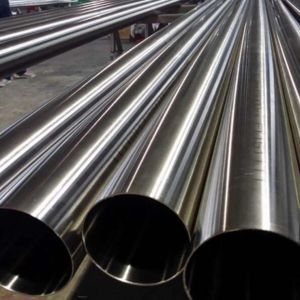

ASTM A335 Grade P91 seamless pipes are top-notch alloy steel pipes crafted to meet the ASTM A335 standard, specifically tailored for high-temperature and high-pressure applications in power plants and the petrochemical sector. Companies like Bosega Pipes & Tubes in Cape Town, South Africa, supply these pipes, which are made from a robust chromium-molybdenum-vanadium steel blend. This unique composition provides outstanding strength, creep resistance, and thermal stability. Thanks to their seamless design, these pipes boast excellent mechanical integrity, making them perfect for critical uses like steam pipelines, heat exchangers, and pressure vessels that operate under high temperatures.

When it comes to their chemical makeup, ASTM A335 Gr P91 pipes generally contain around 0.10% carbon, 8.5-9.5% chromium, 0.85-1.05% molybdenum, 0.20-0.50% vanadium, along with trace amounts of manganese, silicon, phosphorus, and sulfur. These components work together to give the pipes impressive tensile strength (at least 585 MPa) and yield strength (at least 415 MPa), along with excellent creep rupture strength and resistance to thermal fatigue. Plus, they offer good weldability and toughness, whether at room temperature or when heated.

| ASTM A335 Alloy Steel P91 Pipe Size | : | 1/8NB TO 24NB IN |

| Alloy Steel ASTM A335 P91 Standards | : | ASTM A 335, ASME SA 335, UNS K11522 |

| ASTM A335 P91 Alloy Steel Pipe Type | : | Seamless |

| ASTM A335 Alloy Steel P91 Specialized in | : | Large Diameter Size |

| ASTM A335 Alloy Steel P91 Pipe Outer Dimensions | : | 19.05 – 114.3mm |

| Alloy Steel ASTM A335 P91 Pipe Wall Thickness | : | 2.0 – 14 mm |

| Alloy Steel ASTM A335 P91 Pipe Suppliers Length | : | max 16000mm |

| ASME SA335 P91 Alloy Steel Pipe Schedule | : | Schedule 20 – Schedule XXS (heavier on request) up to 250 thk. |

| ASTM A335 Alloy Steel Pipe Form | : | Round, Square, Rectangular, Hydraulic Etc. |

| Alloy Steel ASTM A335 P91 Pipe Length | : | Single Random, Double Random & Cut Length. |

| ASTM A335 P91 Pipe End | : | Plain End, Beveled End, Treaded |

| Grade | C % | Mn % | P % | S % | Si % | Cr % | Mo % |

|---|---|---|---|---|---|---|---|

| P91 | 0.08-0.12 | 0.30-0.60 | 0.020 max | 0.010 max | 0.20 -0.50 | 8.00 – 9.50 | 0.85 – 1.05 |

| Grade | Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

|---|---|---|---|

| P91 | 585 min | 415 min | 20 min |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing ASTM A335 Gr P91 Seamless Pipe from Bosega Pipes and Tubes ensures superior corrosion resistance, excellent thermal conductivity, high strength, and long-lasting performance. Our commitment to quality and precision makes our pipes and tubing ideal for demanding industrial applications.

Bosega Pipes and Tubes is the largest supplier of ASTM A335 Gr P91 Seamless Pipe in Cape Town, South Africa. We offer premium-quality, corrosion-resistant pipes and tubing ideal for marine, chemical, and industrial applications, with our reliable delivery and customized solutions to meet diverse client needs.

Yes, custom sizes are available for ASTM A335 Gr P91 Seamless Pipe to meet specific requirements. These pipes can be tailored for various industrial applications. For more details, contact us at sales@bosegapipes.co.za.

You’ll find ASTM A335 Grade P91 seamless pipes widely used in ultra-supercritical power plants, boilers, heat exchangers, nuclear reactors, and petrochemical processing facilities. They’re perfect for transporting high-temperature fluids and gases, where durability and resistance to oxidation, corrosion, and creep deformation are essential. With their exceptional mechanical and thermal properties, these pipes are the go-to choice for demanding industrial settings that require long-lasting performance and reliability, even in extreme conditions.

©2024 Bosega Pipes and Tubes . All Rights Reserved.