Home > Carbon Steel > Carbon Steel ERW Pipe

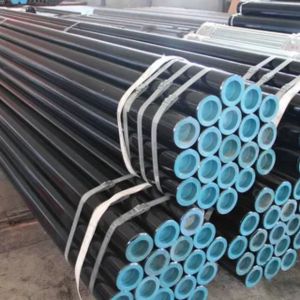

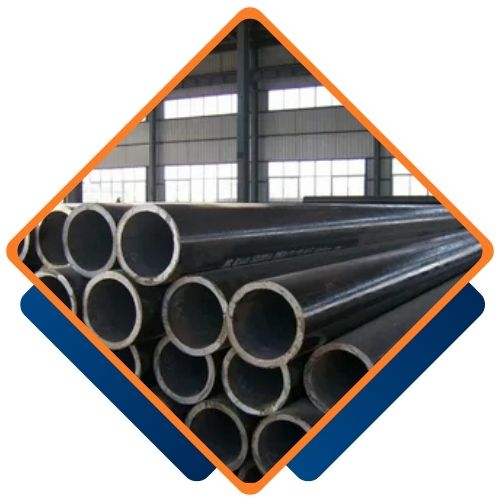

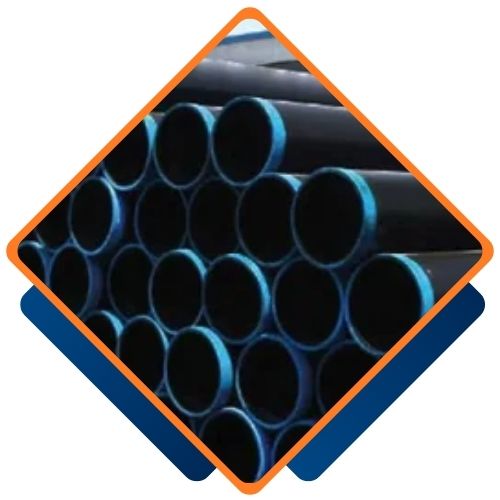

Bosega Pipes and Tubes, located in the vibrant city of Cape Town, South Africa, stands out as a top-notch manufacturer and supplier of premium Carbon Steel ERW (Electric Resistance Welded) Pipes. Renowned for their durability, reliability, and cost-effectiveness, Bosega’s ERW pipes find their way into a variety of industries, including construction, oil and gas, water supply, automotive, and mechanical engineering. Crafted with cutting-edge ERW technology and rigorous quality control, these pipes boast impressive dimensional accuracy, smooth surfaces, and robust weld integrity, ensuring they perform exceptionally well even in the toughest conditions.

The production of Carbon Steel ERW Pipes involves cold-forming carbon steel strips into cylindrical shapes and fusing the edges through electric resistance welding. This method results in a strong, uniform weld with minimal heat distortion. These pipes are known for their excellent mechanical properties, such as high tensile strength, ductility, and corrosion resistance. They come in various grades, including ASTM A53, API 5L, and IS 3589, tailored to meet specific application needs.

Standard : ASTM A53, A106, API 5L, ASME B36

Size : 1/2” NB – 24” NB

Materials : Q235, Q345, A53B, A106B, API 5L B, X42, X46, X52, X60, X65

Wall Thickness : SCH10,SCH20,SCH30,STD,SCH40,SCH60,XS,SCH80,SCH100,SCH120,SCH140,SCH160,XXS DIN, JIS standard thickness

Length : Fixed: 5.8, 6.0, 11.8, 12.0m Random length: 5-12m

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Carbon Steel ERW Pipe from Bosega Pipes and Tubes ensures outstanding corrosion resistance, high strength, and durability. Our Pipe is designed for diverse industrial applications, delivering reliability and performance in challenging environments while maintaining competitive pricing.

Bosega Pipes and Tubes is one of the largest Carbon Steel ERW Pipe suppliers in Cape Town, South Africa, providing a comprehensive range of high-quality pipes tailored for various industries, ensuring reliable delivery and exceptional service to meet diverse project needs.

| Nominal | Pipe size | OD mm | Schedule 20 | Schedule 30 | Schedule STD | Schedule 40 | Schedule 60 | Schedule Extra | Strong (XS) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mm | Inch | Wall | Wt. | Wall | Wt. | Wall | Wt. | Wall | Wt. | Wall | Wt. | Wall | Wt. | |

| 3 | 1/8 | 10.3 | 1.73 | 0.37 | 1.73 | 0.357 | 2.41 | 0.47 | ||||||

| 6 | ¼ | 13.7 | 2.24 | 0.63 | 2.24 | 0.625 | 3.02 | 0.804 | ||||||

| 10 | 3/8 | 17.1 | 2.31 | 0.84 | 2.31 | 0.84 | 3.2 | 1.1 | ||||||

| 15 | ½ | 21.3 | 2.77 | 1.26 | 2.77 | 1.26 | 3.73 | 1.62 | ||||||

| 20 | ¾ | 26.7 | 2.87 | 1.69 | 2.87 | 1.68 | 3.91 | 2.2 | ||||||

| 25 | 1 | 33.4 | 3.38 | 2.5 | 3.38 | 2.5 | 4.55 | 3.24 | ||||||

| 32 | 11/4 | 42.2 | 3.56 | 3.39 | 3.56 | 3.38 | 4.85 | 4.47 | ||||||

| 40 | 11/2 | 48.3 | 3.68 | 4.05 | 3.68 | 4.05 | 5.08 | 5.41 | ||||||

| 50 | 2 | 60.3 | 3.9 | 5.44 | 3.9 | 5.44 | 5.5 | 7.48 | ||||||

| 65 | 21/2 | 73 | 5.2 | 8.63 | 5.16 | 8.63 | 7 | 11.41 | ||||||

| 80 | 3/8 | 88.9 | 5.5 | 11.3 | 5.5 | 11.3 | 7.62 | 15.3 | ||||||

| 90 | 31/2 | 1.6 | 5.74 | 13.57 | 5.74 | 13.57 | 8.08 | 18.63 | ||||||

| 100 | 4 | 114.3 | 6.02 | 16.07 | 6.02 | 16.07 | 8.56 | 22.3 | ||||||

| 125 | 5 | 141.3 | 6.6 | 21.77 | 6.55 | 21.77 | 9.53 | 30.9 | ||||||

| 150 | 6 | 168.3 | 7.11 | 28.26 | 7.11 | 28.26 | 10.97 | 42.5 | ||||||

| 200 | 8 | 219.1 | 6.35 | 33.3 | 7 | 36.8 | 8.2 | 42.5 | 8.2 | 42.5 | 10.3 | 53.1 | 12.7 | 64.6 |

| 250 | 10 | 273 | 6.35 | 41.7 | 7.8 | 51.3 | 9.27 | 60.3 | 9.27 | 60.3 | 12.7 | 81.5 | 12.7 | 81.5 |

| 300 | 12 | 323.9 | 6.35 | 49.7 | 8.4 | 65.2 | 9.53 | 73.8 | 10.3 | 79.7 | 14.3 | 109 | 12.7 | 97.4 |

| 350 | 14 | 355.6 | 7.92 | 68.1 | 9.53 | 81.3 | 9.53 | 81.3 | 11.13 | 94.3 | 15.1 | 126.4 | 12.7 | 107 |

| 400 | 16 | 406.4 | 7.92 | 77.9 | 9.5 | 93.3 | 9.53 | 93.3 | 12.7 | 123 | 16.7 | 160 | 12.7 | 123 |

| 450 | 18 | 457.2 | 7.92 | 87.8 | 11.1 | 122 | 9.53 | 105 | 14.3 | 156 | 19 | 206 | 12.7 | 130 |

| 500 | 20 | 508 | 9.53 | 117.2 | 12.7 | 155.1 | 9.53 | 177.2 | 15.1 | 183 | 20.6 | 248 | 12.7 | 155.1 |

| 550 | 22 | 558.8 | 9.53 | 129 | 12.7 | 171 | 9.53 | 129 | 22.2 | 294 | 12.7 | 171 | ||

| 600 | 24 | 609.6 | 9.53 | 141 | 14.3 | 210 | 9.53 | 141 | 17.4 | 255 | 24.5 | 355 | 12.7 | 187 |

Yes, we offer custom sizes for Carbon Steel ERW Pipe to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

Carbon Steel ERW Pipes are widely utilized for transporting water and gas, constructing structural frameworks, scaffolding, and in mechanical systems. Their unique blend of strength, weldability, and affordability makes them a go-to choice for projects that demand durability, precision, and reliable performance across both industrial and commercial sectors.

©2024 Bosega Pipes and Tubes . All Rights Reserved.