Home > Copper Nickel > Copper Nickel ERW Pipes

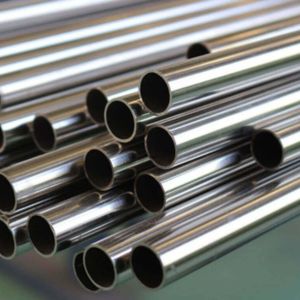

Copper Nickel ERW (Electric Resistance Welded) pipes are top-notch alloy pipes primarily crafted from copper and nickel, specifically designed to withstand the harsh conditions of seawater corrosion, biofouling, and erosion. Companies like Bosega Pipes & Tubes in Cape Town, South Africa, are known for manufacturing and supplying these pipes, which are made using the electric resistance welding process. This method guarantees strong, precise, and seamless joints. With their remarkable mechanical strength, thermal stability, and smooth internal finish, Copper Nickel ERW pipes are perfect for marine, offshore, and heat transfer applications where reliability and corrosion resistance are a must.

Typically, these pipes consist of 90% copper and 10% nickel (Cu-Ni 90/10) or 70% copper and 30% nickel (Cu-Ni 70/30), with small amounts of iron and manganese added to boost strength and resistance to seawater impingement. The alloy boasts a tensile strength between 275 to 450 MPa, a yield strength of 105 to 180 MPa, and elongation rates ranging from 30% to 45%. The ERW manufacturing process creates a uniform weld bead without the need for filler materials, ensuring consistent mechanical properties and smooth, corrosion-resistant surfaces that optimize fluid flow and performance.

Specifications : ASTM / ASME SB 111 / 151 / 466

Standard : ASTM, ASME and API

Size : 1/2″ TO 6′ IN OD & NB IN Various SWG & SCH

Outer Diameter : 4.00 to 22.00 mm

Well Thickness : Between 0.15mm and 1.50 mm

Length : Single Random, Double Random & Required Length

Schedule : SCH20, SCh20, SCh30, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Types : Seamless / ERW / Welded / EFW / Fabricated / CDW

Form : Round Pipes, Square Pipes, Rectangular Pipe

End : Plain End, Beveled End, Treaded

Grades : Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

| Cu-Ni 90-10 | 88.6 min | 1.0 max | .05 max | 9-11 max | 1.8 max | 1 max |

| Cu-Ni 70-30 | 65.0 min | 1 max | .05 max | 29-33 | 0.4-1.0 | 1 max |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Copper Nickel 90-10 / 70-30 | 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 90-1000 psi | 30 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choose Copper Nickel ERW Pipes from Bosega Pipes and Tubes for their exceptional corrosion resistance, high strength, and durability. These pipes are ideal for marine, chemical, and offshore applications, offering long-lasting performance and superior reliability.

Bosega Pipes and Tubes is the largest supplier of Copper Nickel ERW Pipes in Cape Town, South Africa, providing top-quality, corrosion-resistant pipes and tubing ideal for marine, industrial, and chemical applications, with reliable delivery and excellent customer service.

Yes, custom sizes are available for Copper Nickel ERW Pipes to meet specific project requirements. These pipes can be tailored for various industrial applications. For more details, contact us at sales@bosegapipes.co.za.

Copper Nickel ERW pipes find extensive use in marine engineering, shipbuilding, and offshore industries for applications like seawater cooling, ballast systems, condensers, and desalination plants. Their outstanding resistance to saltwater corrosion and biofouling makes them ideal for heat exchangers and condenser tubing in power plants and desalination facilities. Additionally, they are utilized in chemical processing, HVAC systems, and firewater lines where long-lasting durability and reliability are crucial. The combination of excellent corrosion resistance, high thermal conductivity, and ease of fabrication makes Copper Nickel ERW pipes the go-to choice for demanding coastal and industrial environments.

©2024 Bosega Pipes and Tubes . All Rights Reserved.