Home >Incoloy> Incoloy 825 Pipe

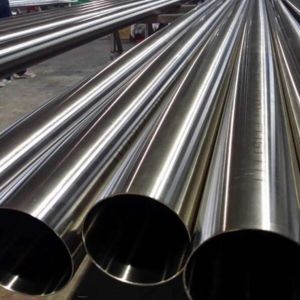

Bosega Pipes and Tubes, located in Cape Town, South Africa, has built a solid reputation as a reliable manufacturer and supplier of Incoloy 825 Pipes. They specialize in providing top-notch solutions for industries that demand exceptional corrosion resistance and durability. With a focus on precision engineering and strict adherence to quality standards, Bosega guarantees that every Incoloy 825 Pipe meets international specifications. These pipes are perfect for challenging environments where resistance to both oxidizing and reducing agents is essential. Committed to excellence, Bosega caters to sectors like chemical processing, power generation, and marine applications, delivering dependable and long-lasting piping solutions that enhance operational efficiency and safety.

Incoloy 825 Pipes are primarily made of nickel, iron, and chromium, with small amounts of molybdenum, copper, and titanium added to boost corrosion resistance. This alloy showcases impressive mechanical properties, such as high tensile strength, good elongation, and outstanding creep and stress-rupture resistance at elevated temperatures. It remains stable in both oxidizing and reducing environments and effectively resists pitting, crevice corrosion, and stress corrosion cracking. These features make Incoloy 825 Pipes a trustworthy choice for long-term use in harsh chemical and industrial settings, ensuring both safety and performance.

| Standard | ASTM B423, B705 / ASME SB 423, SB 705 |

| Standard | ASTM, ASME and API |

| Size | 15 NB UP TO 600 NB IN SCH 5S, 10S,10, 20, 40S, 40, STD, 60, 80S, 80, XS, 100, 120, 140, 160 & XXS |

| Length | Single Random, Double Random & Required Length, Cut Length |

| End | Plain End, Beveled End, Treaded |

| Inconel 825 | Min |

| Ni | 38.0 – 46.0 |

| C | 0.05 max |

| Mn | 1.0 max |

| Si | 0.5 max |

| Cr | 19.5 – 23.5 |

| Fe | 22.0 min |

| Al | 0.2 max |

| Ti | 0.6 – 1.2 |

| cu | 1.5 – 3.0 |

| S | 0.015 max |

| Element | Inconel 825 |

| Density | 8.14 g/cm3 |

| Melting Point | 1400 °C (2550 °F) |

| Tensile Strength | Psi – 80,000 , MPa – 550 |

| Yield Strength (0.2%Offset) | Psi – 32,000 , MPa –220 |

| Elongation | 30 % |

| Hardness (Brinell) | – |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Incoloy 825 Pipe from Bosega Pipes and Tubes ensures superior corrosion resistance, excellent thermal conductivity, high strength, and long-lasting performance. Our commitment to quality and precision makes our pipes and tubing ideal for demanding industrial applications.

Bosega Pipes and Tubes is the largest supplier of Incoloy 825 Pipe in Cape Town, South Africa. We offer premium-quality, corrosion-resistant pipes and tubing ideal for marine, chemical, and industrial applications, with our reliable delivery and customized solutions to meet diverse client needs.

Yes, custom sizes are available for Incoloy 825 Pipe to meet specific requirements. These pipes can be tailored for various industrial applications. For more details, contact us at sales@bosegapipes.co.za.

Incoloy 825 Pipes find extensive use in chemical processing plants, especially for handling sulfuric and phosphoric acids, as well as in nitric acid applications. They are also well-suited for marine environments, desalination plants, and offshore oil and gas operations due to their remarkable resistance to chloride-induced corrosion. Furthermore, these pipes are utilized in pollution control equipment, heat exchangers, and power generation systems, where high temperatures and corrosive conditions are common. Their durability and reliability make them a go-to option for industries looking for long-lasting solutions that reduce maintenance, boost safety, and ensure smooth operations.

©2024 Bosega Pipes and Tubes . All Rights Reserved.