Home > Incoloy > Incoloy Tubing

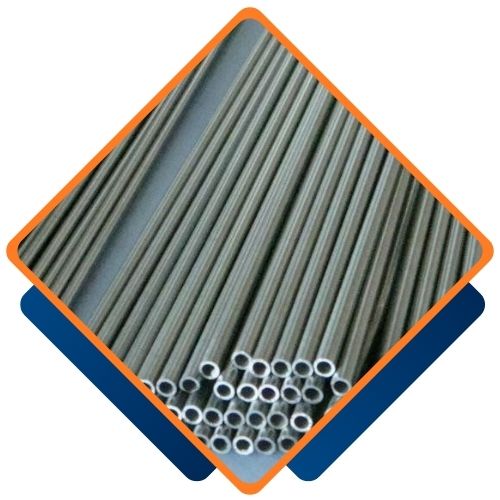

Bosega Pipes and Tubes is a well-respected manufacturer and supplier of Incoloy Tubing based in Cape Town, South Africa. They specialize in providing high-performance tubing solutions that are designed to be strong, resistant to corrosion, and durable even in the toughest environments. Incoloy, which is a nickel-iron-chromium alloy, is specifically crafted to withstand oxidation, carburization, and chemical corrosion, especially in high-temperature and high-pressure situations. Bosega takes pride in their precision manufacturing, ensuring uniform wall thickness, smooth surfaces, and excellent dimensional accuracy. This commitment results in reliable tubing solutions that adhere to global quality standards, making them suitable for industries like power generation, chemical processing, marine, and oil & gas.

Incoloy Tubing primarily consists of nickel (30–46%), chromium (19–23%), and iron, with additional elements like molybdenum, copper, and titanium depending on the specific grade, such as Incoloy 800, 800H, 825, and others. This unique blend significantly boosts resistance to oxidation, pitting, and stress-corrosion cracking. On the mechanical side, Incoloy Tubing boasts high tensile and yield strength, excellent creep resistance, and outstanding thermal stability, ensuring it performs consistently well in aggressive environments.

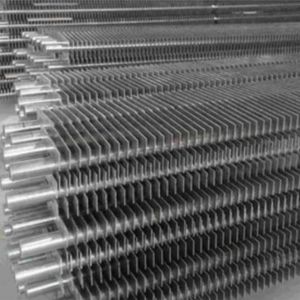

| Application | Oil Tube, Gas Tube, Fluid Tube, Boiler and Heatexchanger |

|---|---|

| Incoloy Seamless Tube Size | 3.35 mm OD To 101.6 mm OD |

| Specialize in | Incoloy Capillary Tube & Other Odd Size Incoloy Heat Exchanger & Condenser Tubes |

| Incoloy tubing wall thickness | 0.020″ –0.220″, (special wall thicknesses available) |

| Incoloy Alloy tube Length | Single Random, Double Random, Standard & Cut length |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Incoloy Alloy Tube Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

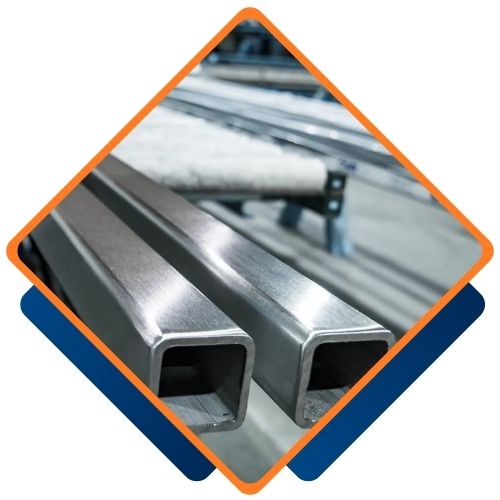

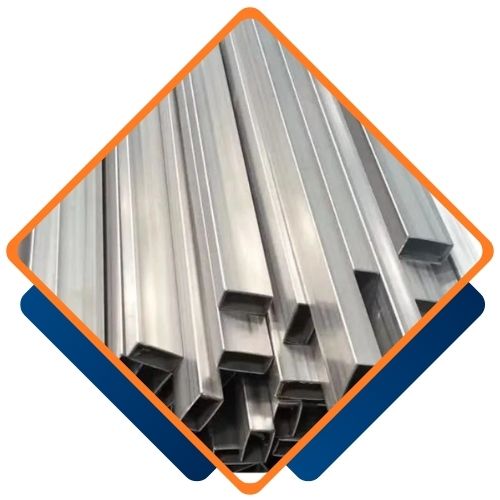

| Incoloy tube Form | Round, Coil, Square, Rectangular, Boiler, Hydraulic, Straight or ‘U’ bent Tubes, Hollow, LSAW Tubes Etc. |

| Incoloy Welded Tube Size | 6.35 mm OD To 152 mm OD |

| End | Plain End, Beveled End, Treaded |

| Incoloy Tube Standards | ASTM B163, B516 / ASME SB163, ASME SB516 |

| Marking | All Incoloy Alloy tubes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| Incoloy Tube Type | Seamless, ERW, EFW, Welded, Fabricated |

| Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| Test Certificate | Manufacturer Test Certificate Laboratory Test Certificate from Govt. Approved Lab. Under Third Party Inspection |

| Wall | Sizes ( O.D.) |

|---|---|

| .010 | 1/16″ , 1/8″ , 3/16″ |

| .020 | 1/16″ , 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ |

| .012 | 1/8″ |

| .016 | 1/8″ , 3/16″ |

| .028 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 3/4″ , 1″ , 1 1/2″ , 2″ |

| .035 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 7/16″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .049 | 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/8″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .065 | 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 3/4″ , 2″ , 2 1/2″ , 3″ |

| .083 | 1/4″ , 3/8″ , 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 7/8″ , 2″ , 2 1/2″ ,3″ |

| .095 | 1/2″ , 5/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .109 | 1/2″ , 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .120 | 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 2 1/4″ , 2 1/2″ , 3″ |

| .125 | 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 3″ , 3 1/4″ |

| .134 | 1″ |

| .250 | 3″ |

| .375 | 3 1/2″ |

| Element | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| Incoloy | 0.10 max | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Incoloy Tubes from Bosega Pipes and Tubes ensures superior quality and durability, offering outstanding corrosion resistance and high strength. Our dedication to delivering exceptional service and reliable products guarantees customer satisfaction across a wide range of industrial applications. With our expertise in Incoloy solutions, you can trust us to provide a top-tier, customized piping solution that meets your specific requirements.

Bosega Pipes and Tubes, one of the largest suppliers of Incoloy Tubing in the Cape Towns, South Africa. Offers a wide range of high-quality pipes and tubes designed for various industrial applications. Their extensive inventory and dedication to exceptional service make them a trusted choice for Incoloy products in the region, delivering reliable solutions to meet diverse project requirements.

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Incoloy | 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa – 205 | 30 % |

Yes, we provide custom sizes for Incoloy Tubes to meet your specific requirements. At Bosega Pipes and Tubes, our team is dedicated to delivering tailored solutions for all your piping and tubing needs. For more information, please contact us at sales@bosegapipes.co.za.

This type of tubing is widely utilized in sectors that demand high corrosion and heat resistance, including chemical processing, power generation, marine engineering, heat exchangers, and petrochemical plants. It’s particularly well-suited for high-temperature equipment like superheaters, condensers, and reheaters. The alloy’s remarkable ability to maintain its structural integrity under stress and extreme conditions makes it a dependable choice for challenging industrial and offshore applications.

©2024 Bosega Pipes and Tubes . All Rights Reserved.