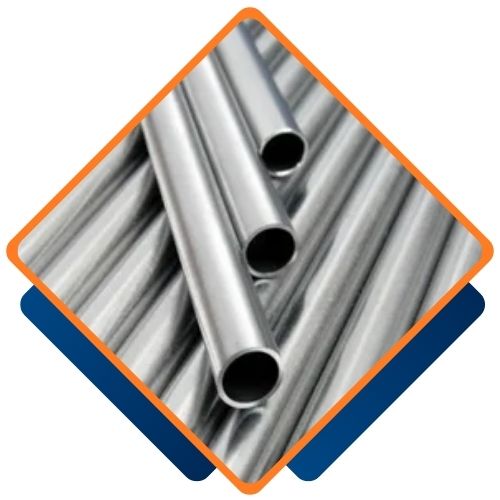

Bosega Pipes and Tubes, located in Cape Town, South Africa, has earned a solid reputation as a reliable manufacturer and supplier of Monel Seamless Tubing, known for its precision engineering and top-notch quality. With a strong focus on excellence, Bosega delivers tubing solutions that adhere to strict industrial standards, ensuring dependability even in tough environments. Their Monel Seamless Tubing is produced using cutting-edge techniques that guarantee uniformity, strength, and resistance to corrosion, making it perfect for industries that demand high-performance materials. Clients in the chemical, marine, and aerospace sectors trust Bosega for durable tubing that blends technical precision with long-lasting performance, establishing them as a go-to choice in South Africa and beyond.

Monel Seamless Tubing is made up of about 67% nickel and 30% copper, along with small amounts of iron, manganese, carbon, and silicon. This unique blend gives it remarkable mechanical properties, such as high tensile strength, impressive yield strength, and excellent elongation. It maintains its shape under high temperatures and resists deformation when under stress. Additionally, Monel Seamless Tubing showcases outstanding corrosion resistance in harsh environments like seawater and acidic conditions, making it a reliable option for demanding industrial uses. Its combination of toughness, durability, and workability ensures it performs exceptionally well across various operational scenarios.

Monel Seamless Tubes : ASTM B165, B163 / ASME SB165, SB163

Tube Size : 4 to 219mm W. T.: 0.5 to 20mm

Schedule : SSCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Type : Seamless / ERW / Welded / Fabricated Pipes

Form : Round Tubes, Square Tubes, Rectangular Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes

Length : Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

End Protection : Plastic Caps

Inspection, Test Reports : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing : Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials : Sizes and Specifications other than above can be manufactured on request

| Grade | Ni | Fe | C | Mn | Si | Cu | Al | Ti | S |

|---|---|---|---|---|---|---|---|---|---|

| K500 | 63.0 min | 05 – 2 | 0.25 max | 1.5 max | 0.5 max | 27.0 – 33.0 | 2.3 – 3.15 | 0.35 – 0.85 | 0.010 max |

| 400 | 63.0- 70.00 max | 2.50 max | 0.3 max | 2.00 max | 0.50 max | Remainder | – | – | 0.024 max |

| Grade | Tensile (ksi) | .2% Yield (ksi) | Elongation % | Hardness (HRb) |

|---|---|---|---|---|

| 400 | 75 to 90 | 25 to 50 | 60 to 35 | 60 to 80 |

| K500 | Psi – 1,60,000 , MPa – 1100 | Psi – 1,15,000 , MPa – 790 | 20 % | – |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Monel Seamless Tubing from Bosega Pipes and Tubes ensures outstanding corrosion resistance, high strength, and durability. Our tubing is designed for diverse industrial applications, delivering reliability and performance in challenging environments while maintaining competitive pricing.

Bosega Pipes and Tubes, one of the largest suppliers of Monel Seamless Tubing in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Our extensive inventory and commitment to exceptional service make us the go-to choice for Monel products in the region.

Yes, we offer custom sizes for Monel Seamless Tubing to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

Monel Seamless Tubing is widely used in marine engineering, chemical processing, and aerospace industries due to its impressive corrosion resistance and strength. It’s commonly found in piping systems, heat exchangers, condenser tubes, and pressure vessels where exposure to seawater, acids, or alkalis is frequent. The tubing is also ideal for valves, pumps, and other high-stress components in power plants, offshore rigs, and desalination facilities. Its ability to endure extreme conditions without breaking down makes it a top choice for critical applications that require reliability.

©2024 Bosega Pipes and Tubes . All Rights Reserved.