Home > Stainless Steel > Stainless Steel 310/310S Seamless Tubing

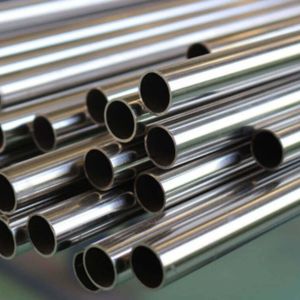

Bosega Pipes and Tubes is a well-respected manufacturer and supplier located in Cape Town, South Africa, focusing on high-performance Stainless Steel 310 and 310S Seamless Pipes. These pipes are celebrated for their outstanding quality, durability, and precision engineering, making them reliable choices for high-temperature and corrosive environments. Bosega employs cutting-edge production methods and strict quality control measures to guarantee consistent performance and precise dimensions. The 310 and 310S seamless pipes from Bosega find extensive use in industries like petrochemical, power generation, and furnace manufacturing, where strength, resistance to oxidation, and longevity are crucial.

Stainless Steel 310 and 310S Seamless Pipes are high-alloy austenitic stainless steels that contain 24–26% chromium and 19–22% nickel, which give them excellent resistance to oxidation and corrosion. The 310S grade, with its lower carbon content, enhances weldability and minimizes carbide precipitation. These pipes boast a tensile strength of around 515 MPa, a yield strength of about 205 MPa, and an elongation of 40%. They maintain remarkable mechanical strength, ductility, and creep resistance even at elevated temperatures, making them perfect for high-heat and oxidative industrial applications.

Tube Range : 6.35 mm OD – 101.6 mm OD, Guage: 20 SWG – 10 SWG

Outer Diameter : 3.00 mm – 219.10 mm

Wall Thickness : 0.40 mm – 12.70 mm

Schedules : 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH

Length : Upto 30 meters, Custom Cut Lengths

Specifications : ASTM A213 / ASTM SA213

Types : Round, Square, Rectangle, Coil, “U” Shape, Hydraulic & Honed Tubes

| SS | 310 | 310S |

| Ni | 19 – 22 | 19 – 22 |

| Fe | Balance | Balance |

| Cr | 24 – 26 | 24 – 26 |

| C | 0.25 max | 0.08 max |

| Si | 1.50 max | 1.50 max |

| Mn | 2 max | 2 max |

| P | 0.045 max | 0.045 max |

| S | 0.030 max | 0.03 max |

| Grade | 310 | 310S |

| Tensile Strength (MPa) min | 515 | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 | 205 |

| Elongation (% in 50mm) min | 40 | 40 |

| Hardness | ||

| Rockwell B (HR B) max | 95 | 95 |

| Brinell (HB) max | 217 | 217 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 310/310S Seamless Tubing from Bosega Pipes and Tubes guarantees exceptional quality and reliability for your industrial needs. Our tubing is crafted from high-grade materials, ensuring excellent oxidation resistance and high-temperature strength, making it ideal for demanding applications in sectors such as aerospace, petrochemical, and power generation. We prioritize customer satisfaction by offering customized solutions tailored to your specific requirements. With our extensive industry experience and commitment to excellence, you can trust Bosega for durable and high-performance stainless steel 310/310S seamless tubing that meets and exceeds your expectations.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel 310/310S Seamless Tubing in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel 310/310S Seamless Tubing to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 310 | S310009 | 310S24 | – | 1.4840 | X15CrNi25-20 | – | SUH 310 |

| 310S | S31008 | 310S16 | – | 1.4845 | X8CrNi25-21 | 2361 | SUS 310S |

In industries that face extreme heat and corrosive conditions, Stainless Steel 310 and 310S Seamless Pipes are widely utilized. They’re commonly found in furnace components, heat exchangers, kilns, power generation plants, petrochemical processing, and thermal oxidizers. These pipes perform exceptionally well in environments exposed to oxidation, sulfur compounds, and cyclic heating. Their smooth internal surface promotes excellent fluid flow and minimizes maintenance needs. With their high mechanical stability and superior corrosion resistance, these pipes are ideal for structural and process applications that demand durability, efficiency, and long-term reliability in challenging operating conditions.

©2024 Bosega Pipes and Tubes . All Rights Reserved.