Home > Stainless Steel > Stainless Steel 316Ti Heat Exchanger Tubing

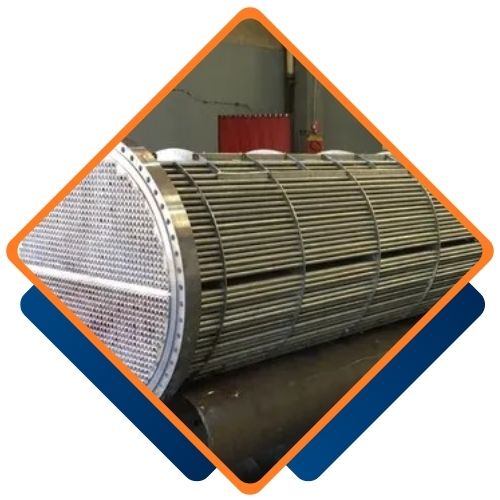

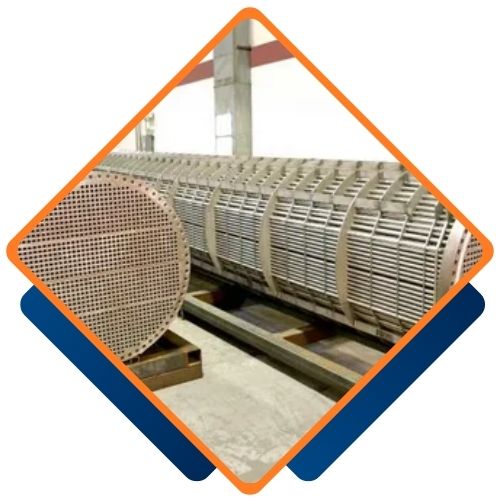

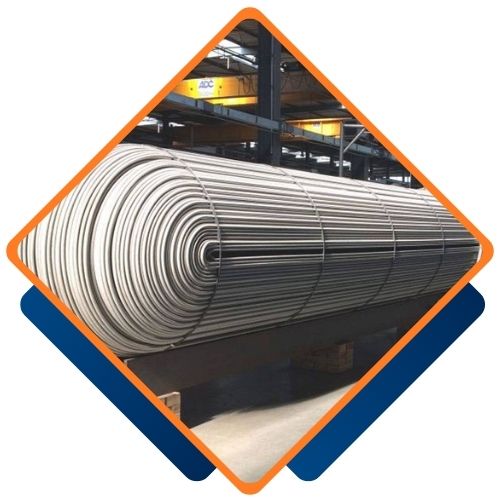

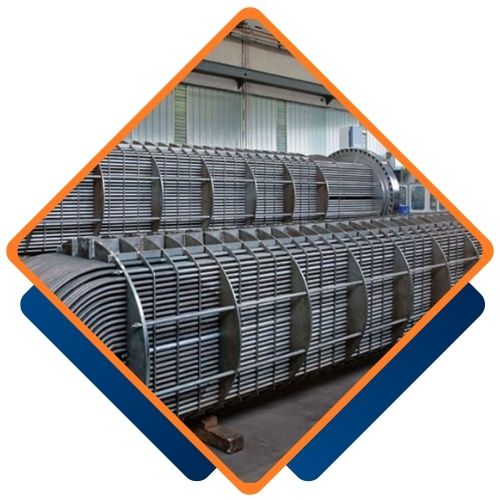

Bosega Pipes and Tubes, based in Cape Town, South Africa, stands out as a reliable supplier and manufacturer of Stainless Steel 316Ti Heat Exchanger Tubing. They specialize in providing high-performance tubing solutions tailored for both thermal and corrosive environments. With a strong focus on quality and dependability, Bosega ensures that their tubing meets rigorous international standards, which guarantees optimal heat transfer efficiency, structural integrity, and impressive corrosion resistance. This tubing finds its place in various industries, including power generation, chemical processing, petrochemicals, pharmaceuticals, and marine systems, where durability and thermal stability are crucial.

Stainless Steel 316Ti is a titanium-stabilized austenitic stainless steel that boasts enhanced resistance to intergranular corrosion and performs better at higher temperatures compared to standard 316. It includes molybdenum, which provides superior protection against pitting and crevice corrosion in environments rich in chlorides. Additionally, the titanium stabilization helps prevent carbide precipitation during welding or exposure to high heat. This combination makes 316Ti an excellent choice for heat exchanger tubing, as it can handle both high temperatures and aggressive fluids. The material is known for its impressive mechanical strength, good thermal conductivity, and long-lasting resistance to oxidation and scaling.

Range : 10 mm OD to 50.8 mm OD

Outer Diameter : 6.00 mm to 101.60 mm

Wall Thickness : 0.70 mm to 8.00 mm

Length : up to 20 m (65.62 ft) Length & Customed Required Length

Specifications : ASTM A 213, A 268, A 269, A 789, Equivalent to ASME, EN, JIS Etc.

| Element | SS 316TI |

| C | 0.08 max |

| Mn | 2.0 max |

| Si | 0.75 max |

| P | 0.045 max |

| S | 0.030 max |

| Cr | 16.00 – 18.00 |

| Mo | 2.00 – 3.00 |

| Ni | 10.00 – 14.00 |

| Fe | 68.395 min |

| Element | SS 316TI |

| Density | 8.0 g/cm3 |

| Melting Point | 1399 °C (2550 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

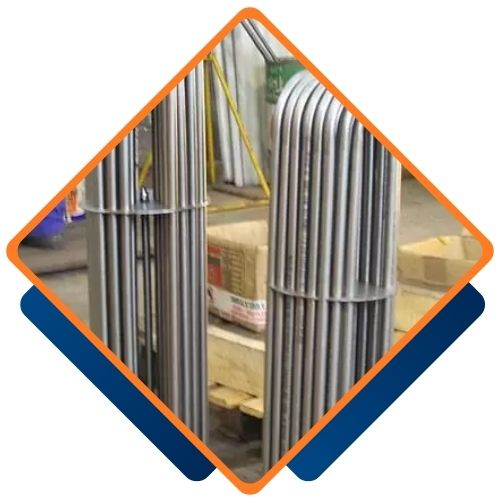

Stainless Steel 316Ti Heat Exchanger Tubing is commonly utilized in condensers, boilers, evaporators, and cooling systems across a variety of demanding industries. Its ability to endure cyclic heating and cooling, along with its resistance to corrosive substances, ensures reliable and efficient performance over extended periods. In settings like marine cooling systems, refineries, and chemical reactors, this tubing delivers long-term operational stability with minimal maintenance required.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel 316Ti Heat Exchanger Tubing in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel 316Ti Heat Exchanger Tubing to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316TI | 1.4571 | S31635 | SUS 316Ti | 320S31 | 08Ch17N13M2T | Z6CNDT17‐123 | X6CrNiMoTi17-12-2 |

Stainless Steel 316Ti Heat Exchanger Tubing is widely used in applications that demand high resistance to corrosion and high-temperature strength. It is ideal for heat exchangers in industries like chemical processing, petrochemicals, and power generation, where tubes are exposed to aggressive chemicals, acids, and high heat. The titanium-stabilized composition allows it to withstand long-term service in environments up to 600°C without compromising its structural integrity. Additionally, it is used in food processing, pharmaceuticals, and marine applications due to its excellent corrosion resistance and durability.

©2024 Bosega Pipes and Tubes . All Rights Reserved.