Home > Stainless Steel > Stainless Steel 321/321H Heat Exchanger Tubing

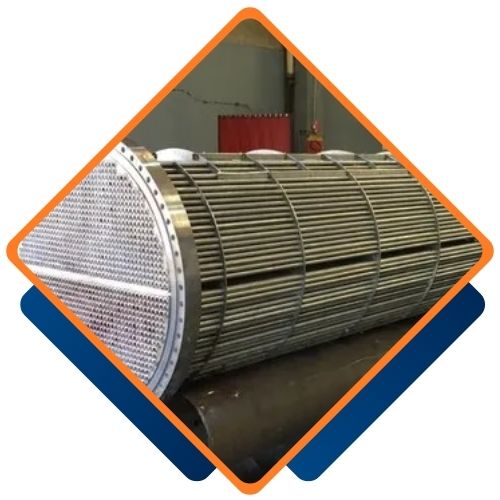

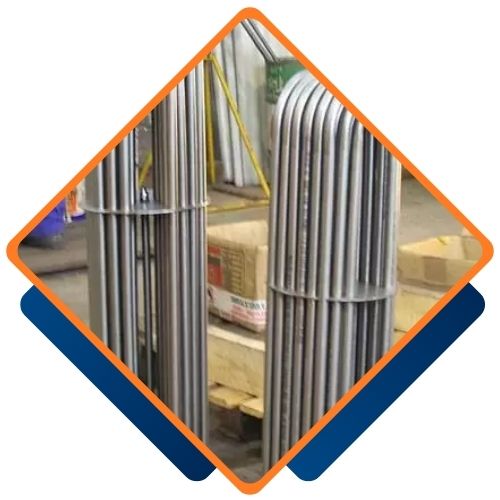

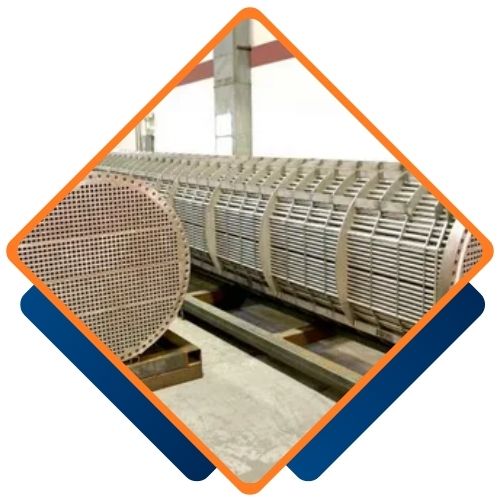

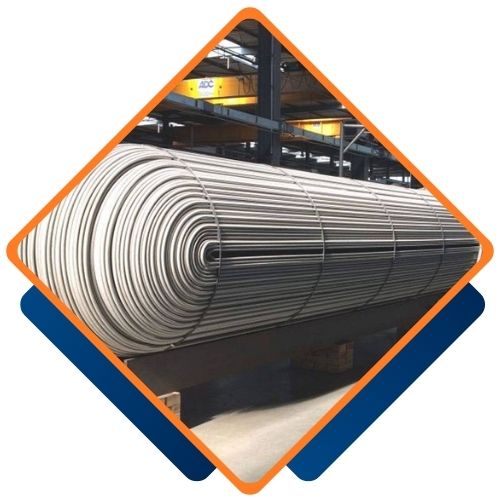

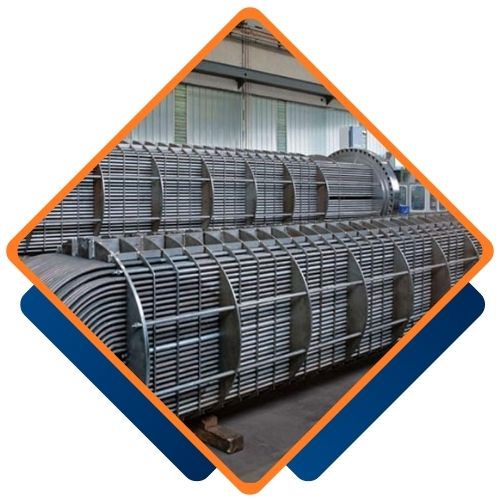

Bosega Pipes and Tubes, based in Cape Town, South Africa, stands out as a premier supplier of **Stainless Steel 321/321H Heat Exchanger Tubing**, designed specifically for high-temperature and corrosive environments. These titanium-stabilized stainless steels are renowned for their exceptional resistance to intergranular corrosion and thermal fatigue, making them perfect for heat exchangers that operate under continuous high-temperature conditions. Manufactured to adhere to rigorous international standards, Bosega’s tubing is celebrated for its precise dimensions, excellent weldability, and reliable long-term performance.

Stainless Steel 321/321H Heat Exchanger Tubing is primarily composed of iron, chromium (18-20%), nickel (9-12%), and titanium (5 times the carbon content). This alloy exhibits excellent mechanical properties, including high tensile strength (up to 758 MPa) and superior resistance to oxidation and corrosion at elevated temperatures. The titanium content enhances its stability, particularly against sensitization during welding. Advantages include excellent weldability, resistance to intergranular corrosion, and high-temperature strength, making it ideal for applications in the aerospace, chemical, and petrochemical industries where durability and performance are crucial.

Range : 10 mm OD to 50.8 mm OD

Outer Diameter : 6.00 mm to 101.60 mm

Wall Thickness : 0.70 mm to 8.00 mm

Length : up to 20 m (65.62 ft) Length & Customed Required Length

Specifications : ASTM A 213, A 268, A 269, A 789, Equivalent to ASME, EN, JIS Etc.

| Element | SS 321 | SS 321H |

| C | 0.08 max | 0.04 – 0.10 |

| Mn | 2.0 max | 2.0 max |

| Si | 1.0 max | 1.0 max |

| P | 0.045 max | 0.045 max |

| S | 0.030 max | 0.030 max |

| Cr | 17.00 – 19.00 | 17.00 – 19.00 |

| N | 0.10 max | 0.10 max |

| Ni | 9.00 – 12.00 | 9.00 – 12.00 |

| Ti | 5(C+N) – 0.70 max | 4(C+N) – 0.70 max |

| Element | SS 321/321H |

| Density | 8.0 g/cm3 |

| Melting Point | 1457 °C (2650 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

**Stainless Steel 321** is an austenitic grade that’s stabilized with titanium to prevent carbide precipitation, providing remarkable strength and oxidation resistance up to 870°C. On the other hand, **321H** is the high-carbon variant of this alloy, offering improved creep resistance and outstanding performance in extended high-temperature applications. The tubing’s seamless design and smooth internal finish promote optimal fluid flow and heat transfer efficiency, while also minimizing the risk of corrosion and contamination in sensitive systems.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel 321/321H Heat Exchanger Tubing in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

These tubes find extensive use in **chemical processing plants**, **petroleum refineries**, **power generation facilities**, and **aircraft engine cooling systems**, where the ability to withstand high temperatures and aggressive media is crucial. They are also perfectly suited for **boiler systems**, **superheaters**, and **gas turbine components**, where consistent performance under thermal stress is vital. Stainless Steel 321/321H Heat Exchanger Tubing from Bosega delivers a dependable and cost-effective solution for demanding thermal applications, ensuring efficient heat transfer and durability in harsh industrial settings.

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 321 | 1.4541 | S32100 | SUS 321 | X6CrNiTi18-10 |

| SS 321H | 1.4878 | S32109 | SUS 321H | X12CrNiTi18-9 |

Stainless Steel 321/321H Heat Exchanger Tubing is widely used in various industries due to its excellent resistance to high temperatures and corrosion. Its primary applications include heat exchangers, condensers, and boilers in oil and gas, petrochemical, and power generation sectors. The alloy’s ability to withstand oxidation and intergranular corrosion makes it ideal for high-stress environments. Additionally, it’s used in chemical processing and food processing industries, where sanitation and durability are crucial. Overall, its versatility and performance make it a preferred choice for demanding thermal applications.

©2024 Bosega Pipes and Tubes . All Rights Reserved.