Home > Stainless Steel > Stainless Steel 321/321H Seamless Tubing

Bosega Pipes and Tubes, located in Cape Town, South Africa, is a reliable supplier of top-notch **Stainless Steel 321/321H Seamless Tubing**, designed to withstand high temperatures and corrosive environments. These titanium-stabilized austenitic stainless steels are specifically formulated to prevent intergranular corrosion when exposed to temperatures that fall within the chromium carbide precipitation range. Bosega ensures that their seamless tubing meets international standards, providing exceptional dimensional accuracy, outstanding strength, and long-lasting durability for critical industrial applications.

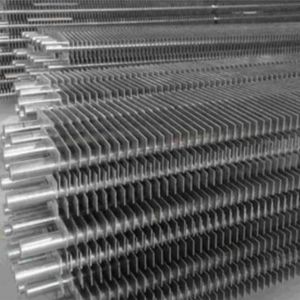

Stainless Steel 321/321H Seamless Tubing consists of iron, 17-19% chromium, 9-12% nickel, and up to 1% titanium, which enhances its resistance to high-temperature oxidation. The mechanical properties include a tensile strength of approximately 515 MPa and a yield strength of around 205 MPa, ensuring excellent durability. The advantages of 321/321H tubing include superior resistance to intergranular corrosion, making it suitable for elevated temperatures. Its titanium addition prevents carbide precipitation, ensuring stability in high-temperature applications. This tubing is ideal for use in chemical processing, aerospace, and petrochemical industries.

Tube Range : 6.35 mm OD To 101.6 mm OD Guage: 25 SWG – 10 SWG

Outer Diameter : 3.00 mm – 219.10 mm

Wall Thickness : 0.40 mm – 12.70 mm

Schedules : 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH

Length : Upto 30 meters, Custom Cut Lengths

Specifications : ASTM A213 / ASTM SA213

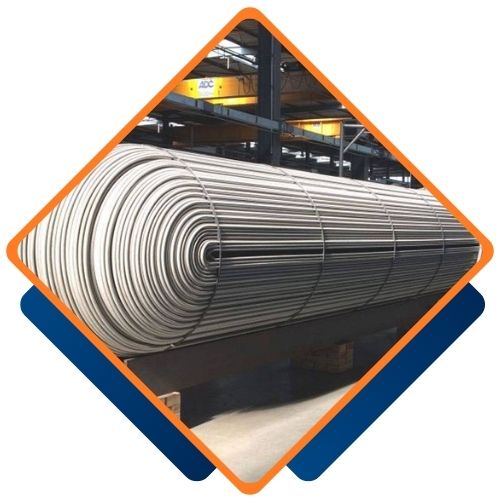

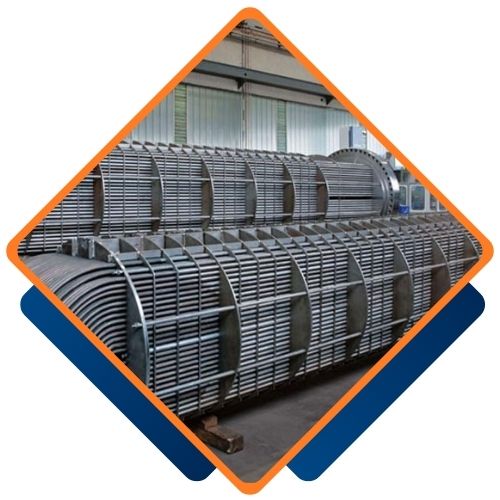

Types : Round, Square, Rectangle, Coil, “U” Shape, Hydraulic & Honed Tubes

| SS | 321 | 321H |

| Ni | 09 – 12 | 09 – 12 |

| N | 0.10 | 0.10 |

| Cr | 17 – 19 | 17 – 19 |

| C | 0.08 max | 0.04 – 0.08 |

| Si | 1 max | 0.75 max |

| Mn | 2 max | 2 max |

| P | 0.040 max | 0.045 max |

| S | 0.030 max | 0.03 max |

| TI | 4(C+N) | 0.70 max |

| Grade | 321 | 321H |

| Tensile Strength (MPa) min | 515 | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 | 205 |

| Elongation (% in 50mm) min | 40 | 40 |

| Hardness | ||

| Rockwell B (HR B) max | 95 | 95 |

| Brinell (HB) max | 217 | 217 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

**Stainless Steel 321** is stabilized with titanium, making it an excellent choice for welding and high-temperature applications up to 870°C. It effectively resists oxidation and stress corrosion cracking in situations involving thermal cycling or exposure to various chemicals. On the other hand, **321H** is a high-carbon variant of 321, which enhances creep strength and delivers superior performance in prolonged high-temperature scenarios. The seamless design of these tubes eliminates the risk of weld failure and ensures consistent strength throughout, making them ideal for pressurized and heat-intensive settings.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel 321/321H Seamless Tubing in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

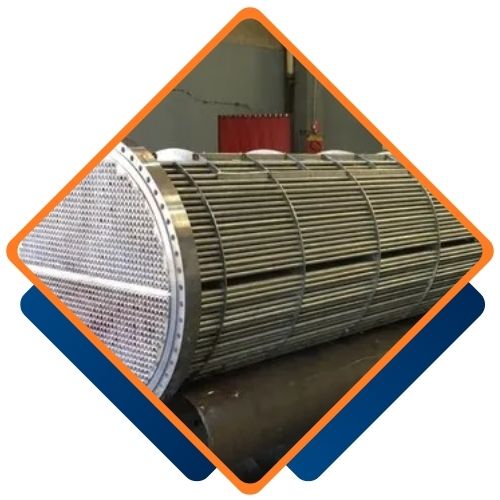

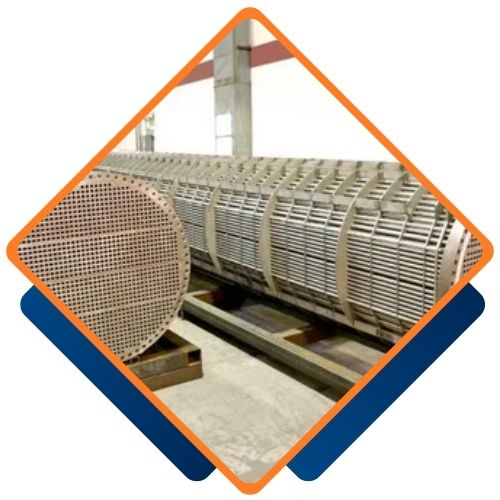

These tubes find extensive use in **heat exchangers**, **furnace components**, **aerospace and jet engine parts**, **petrochemical processing**, and **exhaust systems**, where stability, heat resistance, and corrosion performance are paramount. They are also well-suited for the **pharmaceutical**, **power generation**, and **chemical manufacturing** industries that demand clean, reliable, and high-performance tubing. With Stainless Steel 321/321H Seamless Tubing from Bosega, you get the strength, thermal stability, and resistance necessary for safe and efficient operation in challenging applications.

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 321 | S32100 | 321S31 | 58B, 58C | 1.4541 | X6CrNiTi18-10 | 2337 | SUS 321 |

| 321H | S32109 | 321S51 | – | 1.4878 | X6CrNiTi18-10 | – | SUS 321H |

Stainless Steel 321/321H Seamless Tubing is widely used in high-temperature applications due to its excellent oxidation resistance and mechanical stability. It is commonly employed in the aerospace industry for exhaust systems, fuel lines, and other components exposed to extreme conditions. In the chemical processing sector, this tubing is ideal for handling corrosive substances and in heat exchangers. Additionally, it is used in petrochemical applications, pressure vessels, and power generation equipment. Its durability and reliability make it a preferred choice for critical applications across various industries.

©2024 Bosega Pipes and Tubes . All Rights Reserved.