Home > Stainless Steel > Stainless Steel 347 and 347H Electropolished Pipes

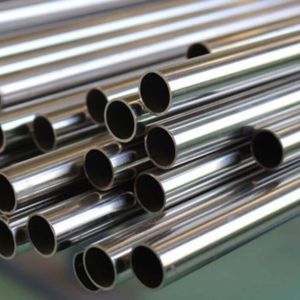

Bosega Pipes and Tubes, located in Cape Town, South Africa, stands out as a top manufacturer and supplier of Stainless Steel 347 and 347H Electropolished Pipes. These pipes are celebrated for their exceptional resistance to corrosion, impressive performance at high temperatures, and incredibly smooth internal finish. Thanks to a specialized electropolishing process, surface imperfections are eliminated, cleanliness is enhanced, and resistance to corrosion and contamination is significantly improved. Bosega caters to essential industries like pharmaceuticals, food processing, chemicals, and petrochemicals, where purity, hygiene, and performance are absolutely critical. Each pipe is crafted to meet international standards, ensuring they deliver consistent, reliable performance even in the most demanding conditions.

Stainless Steel 347 is a stabilized austenitic stainless steel that includes niobium (columbium), which boosts its resistance to intergranular corrosion after welding. On the other hand, 347H is a high-carbon variant of 347, specifically designed to offer better creep strength and withstand higher temperatures. Both alloys provide remarkable mechanical strength, oxidation resistance, and stability in high-heat settings. The electropolished surface greatly reduces roughness, lowers the chances of contamination or bacterial growth, and enhances cleanability—an absolute must in ultra-pure systems. These pipes also maintain good weldability and formability while delivering a superior surface finish and corrosion resistance compared to standard polished or unpolished piping.

| Specifications | : | ASTM A/ASME SA249/A269/A270 |

| Dimensions | : | ASTM, ASME, and API |

| SS 347 and 347H Pipes Size | : | 1/8″NB TO 30″NB IN |

| Thickness | : | 1mm to 20mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10 |

| Finish | : | BA Finish inside and outside, Electropolished finish inside and outside |

| Type | : | Electropolished Pipes & Tubes |

| Form | : | Round, Square, Rectangular, Hydraulic Etc |

| Length | : | Up to 6 meters, custom cut lengths |

| Grade | C | Mn | Si | P | S | Cr | Cb | Ni | Fe |

| SS 347 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 20.00 | 10xC – 1.10 | 9.00 – 13.00 | 62.74 min |

| SS 347H | 0.04 – 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 8xC – 1.10 | 9.0 -13.0 | 63.72 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1454 °C (2650 °F) | Psi – 75000, MPa – 515 | Psi – 30000, MPa – 205 | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 347 and 347H Electropolished Pipes from Bosega Pipes and Tubes guarantees excellent corrosion resistance, high strength, and durability. Designed for diverse industrial applications, it delivers reliable performance in tough environments while maintaining competitive pricing for cost-effective solutions.

Stainless Steel 347 and 347H Electropolished Pipes are perfect for cleanroom piping systems, pharmaceutical water lines, biotechnology process piping, semiconductor manufacturing, and high-purity gas and fluid transport systems. Their smooth, electropolished surface prevents product buildup, promotes laminar flow, and ensures optimal performance in critical applications.

| STANDARD | WERKSTOFF NR. | UNS | JIS | GOST | EN |

| SS 347 | 1.4550 | S34700 | SUS 347 | 08Ch18N12B | X6CrNiNb18-10 |

| SS 347H | 1.4961 | S34709 | SUS 347H | – | X6CrNiNb18-12 |

We offer custom sizes for Stainless Steel 347 and 347H Electropolished Pipes to meet your specific needs. Our dedicated team at Bosega Pipes and Tubes provides tailored solutions for all your piping and tubing requirements. For more information, contact us at sales@bosegapipes.co.za.

Stainless Steel 347 and 347H Electropolished Pipes are widely used in high temperature applications due to corrosion resistance and excellent strength Common applications include chemical process industry for handling corrosives, petrochemical plants for transportation of fuels and chemicals, steam line and heat exchanger power generation For aerospace components requiring high temperature resistance Also used in s sector and food processing and pharmaceuticals. In applications where hygiene and sanitation are of the utmost importance, their smooth surface reduces bacterial growth, making them ideal for detergents.

©2024 Bosega Pipes and Tubes . All Rights Reserved.