Home > Stainless Steel > Stainless Steel 347/347H Seamless Tubing

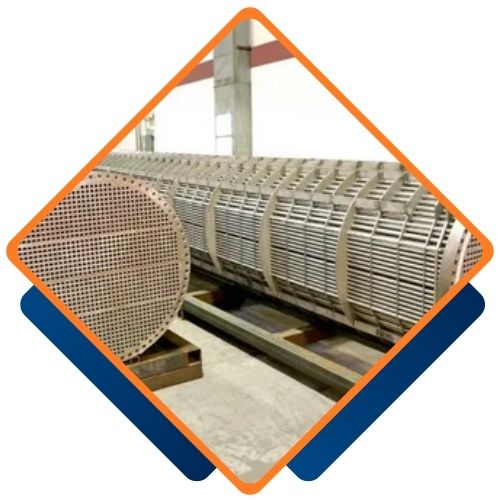

Bosega Pipes and Tubes, located in Cape Town, South Africa, stands out as a trusted manufacturer and supplier of Stainless Steel 347/347H Seamless Tubing. They specialize in providing precision-engineered solutions designed to thrive in high-temperature and corrosive environments. With a reputation for delivering top-notch stainless steel products, Bosega guarantees that every seamless tube adheres to strict dimensional tolerances and international standards. These tubes are perfect for critical sectors like aerospace, petrochemicals, thermal processing, power generation, and refinery systems, where dependable performance under stress and temperature changes is crucial.

Stainless Steel 347 is an austenitic chromium-nickel steel alloy that’s stabilized with niobium (or columbium), which helps prevent intergranular corrosion after welding and exposure to high temperatures. The 347H variant, with its higher carbon content, offers enhanced creep resistance and strength at elevated temperatures. The seamless tubing made from these grades boasts excellent resistance to oxidation, scaling, and high-temperature corrosion, along with solid mechanical properties and weldability. The seamless manufacturing process eliminates the weld seam, ensuring consistent strength and structural integrity, even in high-pressure and high-temperature conditions.

Tube Range : 6.35 mm OD To 101.6 mm OD Guage: 25 SWG – 10 SWG

Outer Diameter : 3.00 mm – 219.10 mm

Wall Thickness : 0.40 mm – 12.70 mm

Schedules : 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH

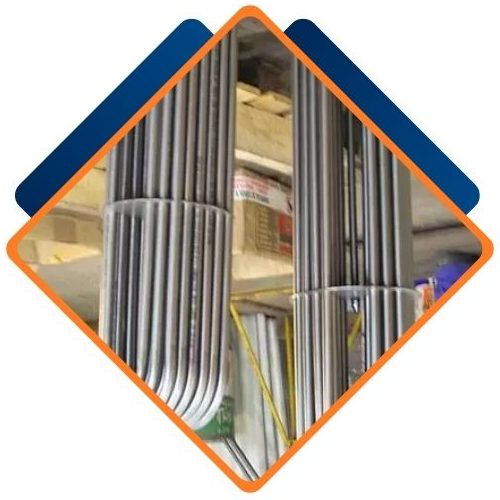

Length : Upto 30 meters, Custom Cut Lengths

Specifications : ASTM A213 / ASTM SA213

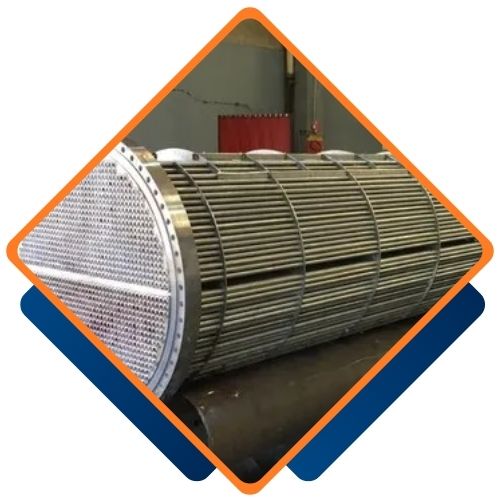

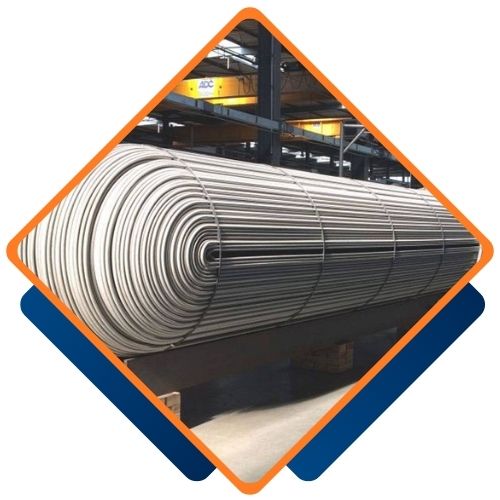

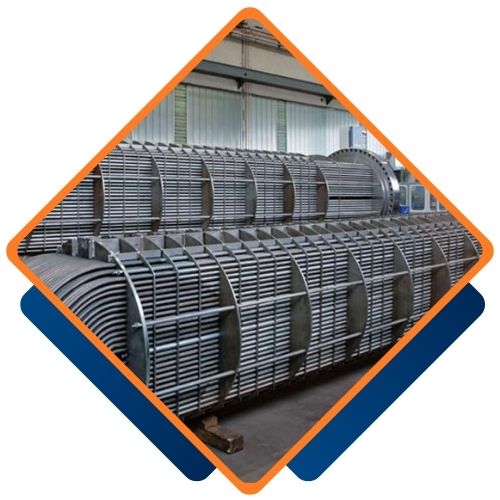

Types : Round, Square, Rectangle, Coil, “U” Shape, Hydraulic & Honed Tubes

| SS | 347 | 347H |

| Ni | 09 – 13 | 09 – 13 |

| N | – | – |

| Cr | 17 – 20 | 17 – 19 |

| C | 0.08 max | 0.04 – 0.08 |

| Si | 1 max | 1 max |

| Mn | 2 max | 2 max |

| P | 0.045 max | 0.045 max |

| S | 0.030 max | 0.03 max |

| OTHER | Nb=10(C+N) – 1.0 | 8xC min – 1.00 max |

| Grade | 347 / 347H |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 40 |

| Hardness | |

| Rockwell B (HR B) max | 92 |

| Brinell (HB) max | 201 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 347/347H seamless tubing from Bosega Pipes and Tubes ensures you receive a product of exceptional quality and reliability. Our tubing is designed to withstand high temperatures and resist intergranular corrosion, making it ideal for demanding applications in the chemical, petrochemical, and aerospace industries. We adhere to strict quality control measures and offer comprehensive testing to ensure optimal performance. Our experienced team provides personalized solutions tailored to your specific requirements, guaranteeing customer satisfaction. Trust Bosega Pipes and Tubes for durable, high-performance seamless tubing that meets the highest industry standards.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel 347/347H Seamless Tubing in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel 347/347H Seamless Tubing to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 347 | S34700 | 347s31 | 58G | 1.4550 | X6CrNiNb18-10 | 2338 | SUS 347 |

Stainless Steel 347/347H Seamless Tubing is widely used in various high-temperature applications due to its excellent resistance to intergranular corrosion. It is commonly employed in the aerospace industry for exhaust systems and fuel lines, where durability is crucial. In the chemical processing sector, this tubing is ideal for handling corrosive substances, particularly in reactors and heat exchangers. Additionally, it finds applications in petrochemical plants, power generation facilities, and nuclear power systems. Its reliability and performance make it a preferred choice for critical components across multiple industries.

©2024 Bosega Pipes and Tubes . All Rights Reserved.