Home > Stainless Steel > Stainless Steel 347 and 347H Seamless Pipes

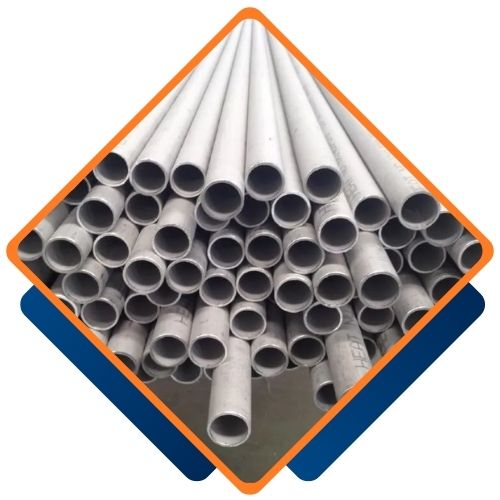

Bosega Pipes and Tubes, based in Cape Town, South Africa, has built a solid reputation as a reliable manufacturer and supplier of top-notch **Stainless Steel 347/347H Seamless Pipes**. These pipes are well-known for their outstanding resistance to intergranular corrosion, impressive high-temperature strength, and remarkable durability over time. Crafted with precision and in line with international standards, Bosega guarantees consistent quality and dependability. The **Stainless Steel 347/347H Seamless Pipes** are perfect for tough industrial applications where performance in harsh environments is a must. They cater to a variety of sectors, including petrochemical, power generation, chemical processing, and aerospace, providing reliable service and exceptional structural integrity.

**Stainless Steel 347/347H Seamless Pipes** are a type of titanium-stabilized austenitic stainless steel, featuring chromium (17–19%), nickel (9–13%), and a touch of titanium to prevent carbide precipitation. The 347H variant has a higher carbon content, which boosts its high-temperature strength. These pipes showcase impressive tensile strength (around 515 MPa), yield strength (205 MPa), and elongation (40%), along with excellent oxidation resistance up to 870°C. They also boast great formability, weldability, and mechanical stability under thermal stress, making them ideal for critical high-temperature applications.

Range : 6NB to 1200NB

Outer Diameter : 1/8″ NPS to 12″ NPS

Thickness : 0.6 mm to 12.7 mm

Schedules : SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS.

Length : Single Random, Double Random & Cut Length

Specifications : ASTM A312 / ASTM SA312

Types : Round, Square, Rectangle, Hydraulic, Honed Tubes

End : Plain End, Beveled End

| STANDARD | UNS | WERKSTOFF NR. |

| SS 347 | S34700 | 1.4550 |

| SS 347H | S34709 | 1.4961 |

| Ni | 09 – 13 | 09 – 13 |

| N | – | – |

| Cr | 17 – 20 | 17 – 19 |

| C | 0.08 max | 0.04 – 0.08 |

| Si | 1 max | 0.75 max |

| Mn | 2 max | 2 max |

| P | 0.045 max | 0.045 max |

| S | 0.030 max | 0.03 max |

| OTHER | Nb=10(C+N) – 1.0 | 8xC min – 1.00 max |

| Grade | 347 / 347H |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 40 |

| Hardness | |

| Rockwell B (HR B) max | 92 |

| Brinell (HB) max | 201 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 347and 347H Seamless Pipes from Bosega Pipes and Tubes guarantees exceptional corrosion resistance and high temperature performance. Their pipes are manufactured to exacting standards, ensuring reliability and durability for complex applications. With a focus on customer service, Bosega offers customized solutions and technical support. In addition, the rugged design reduces leakage, making it reliable for a variety of applications.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel 347 and 347H Seamless Pipes in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 347 | S34700 | 347s31 | 58G | 1.4550 | X6CrNiNb18-10 | 2338 | SUS 347 |

Yes, we offer custom sizes for Stainless Steel 347and 347H Seamless Pipes to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

You’ll find **Stainless Steel 347/347H Seamless Pipes** widely utilized in industries that require high-temperature corrosion resistance and structural reliability. Typical applications include boiler tubes, heat exchangers, pressure vessels, chemical processing equipment, and exhaust systems. They are heavily used in petrochemical plants, power generation, aerospace, and food processing sectors. The blend of durability, thermal stability, and corrosion resistance ensures these pipes perform reliably even in extreme conditions, making them vital for ongoing industrial operations and long-term high-temperature service.

©2024 Bosega Pipes and Tubes . All Rights Reserved.