Home > Stainless Steel >Stainless Steel 405 Pipes

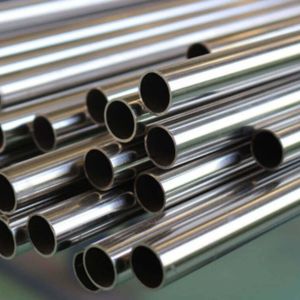

Bosega Pipes and Tubes, based in Cape Town, South Africa, has earned a solid reputation as a reliable manufacturer and supplier of Stainless Steel 405 Pipes. They specialize in providing dependable piping solutions for applications that demand good oxidation resistance and thermal stability. With a strong focus on delivering top-notch stainless steel products that adhere to international standards, Bosega caters to a diverse range of industries, including automotive, heat exchangers, power generation, and industrial processing. Their Stainless Steel 405 pipes are crafted with precision and undergo rigorous quality control to guarantee consistent performance, accurate dimensions, and a long lifespan, even in high-temperature settings.

Stainless Steel 405 is a ferritic stainless steel that contains about 12% chromium along with added aluminum, enhancing its oxidation resistance and helping to manage grain growth during welding and high-heat situations. Unlike austenitic grades, 405 cannot be hardened through heat treatment, but it still provides good corrosion resistance in mildly corrosive environments and excels at resisting scaling at elevated temperatures. Its lower carbon content minimizes the risk of sensitization and intergranular corrosion. With decent mechanical strength and excellent formability, 405 is a cost-effective option for applications where welding, thermal fatigue resistance, and oxidation resistance are crucial.

| Product Name | 405 Stainless Steel Pipe | |

| Type | Steel Pipe | |

| Outer diameter | Round Tube | 4mm-200mm |

| Square Tube | 10*10mm-100*100mm | |

| Rectangular Tube | 10*20mm-50*100mm | |

| Wall Thickness | 0.6mm-6.0mm | |

| Length | 1-6 meters, Length can be customized | |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

| Surface | Black, Bright Polished, Rough Turning, Matt Surface Treatment, No. 4. BA, etc. | |

| Scope of Application | Common applications for stainless steel pipes include food processing,Textile operations, Breweries, Water treatment plants, Oil and gas processing,Fertilizers and pesticides, Chemical applications, Construction, Pharmaceuticals, Auto parts, etc. | |

| Certificate | ISO, SGS, BV, etc. | |

| Production Technology | Hot Rolling, Cold Rolling | |

| Edge Processing | Edging, Trimming | |

| C | Si | Mn | Cr | Ni | S | P |

| ≤ 0.08 | ≤1.0 | ≤1.0 | 11.5~14.5 | ≤ 0.5 | ≤ 0.03 | ≤ 0.04 |

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥485 | ≥275 | ≥25 | ≤ 160HBW |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Stainless Steel 405 Pipes find extensive use in scenarios that involve high temperatures and moderate corrosion, such as exhaust systems, heat exchangers, mufflers, and furnace components. They are also utilized in petrochemical and refining systems where resistance to thermal cycling is vital. Thanks to their ferritic structure, these pipes possess good magnetic properties and are easy to machine and weld, making them a practical choice for various applications.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel 405 Pipes in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(Ω.mm2/m) |

| 7.80 | 200 | 10.8 | 27.0 | 0.6 |

Yes, we offer custom sizes for Stainless Steel 405 Pipes to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

Stainless Steel 405 Pipe is widely used in applications requiring moderate corrosion resistance and high temperature tolerance. They are commonly used in automotive exhaust systems, where their ferritic structure provides high thermal stability and oxidation resistance In the chemical and petrochemical industries, due to corrosion resistance in sensitive environments and due to corrosion, these pipes are used for heat exchangers, hot water and processing equipment s, annealing -Used in the manufacture of boxes and equipment, for durability, machinability and cost.

©2024 Bosega Pipes and Tubes . All Rights Reserved.