Home > Stainless Steel >Stainless Steel 410 Pipes

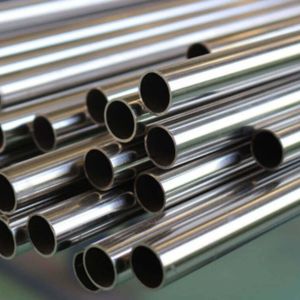

Bosega Pipes and Tubes stands out as a reliable manufacturer and supplier of Stainless Steel 410 Pipes in Cape Town, South Africa. They provide top-notch piping solutions that are designed for strength, durability, and a decent level of corrosion resistance. Stainless Steel 410 is a type of martensitic stainless steel, celebrated for its hardness, wear resistance, and its ability to hold up mechanical strength even at higher temperatures. Bosega takes pride in their precision manufacturing, ensuring smooth surfaces, consistent wall thickness, and strict compliance with international quality standards. This makes their pipes perfect for a variety of applications, including industrial, automotive, petrochemical, and structural uses.

When it comes to composition, Stainless Steel 410 Pipes are mainly made of iron, featuring chromium content between 11.5% and 13.5%, along with trace amounts of carbon, manganese, and silicon to boost hardness and strength. On the mechanical side, these pipes deliver impressive tensile and yield strength, good wear resistance, and moderate ductility. Thanks to their martensitic microstructure, they can be hardened through heat treatment, which enhances their mechanical performance and abrasion resistance while still offering reasonable corrosion resistance in less aggressive environments.

| Specifications | : | ASTM A 312 ASME SA 312 / ASTM A 358 ASME SA 358 |

| Dimensions | : | ASTM, ASME and API |

| SS 410 Pipes | : | 1/2″ NB – 16″ NB |

| ERW 410 Pipes | : | 1/2″ NB – 24″ NB |

| EFW 410 Pipes | : | 6″ NB – 100″ NB |

| Size | : | 1/8″NB TO 30″NB IN |

| Specialized in | : | Large Diameter Size |

| Schedule | : | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | : | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

| Form | : | Round, Square, Rectangular, Hydraulic Etc |

| Length | : | Single Random, Double Random & Cut Length. |

| End | : | Plain End, Beveled End, Treaded |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 410 | min. | – | – | – | – | – | 11.5 | – | – | – |

| max. | 0.15 | 1.0 | 1.00 | 0.040 | 0.030 | 13.5 | – | 0.75 | – | |

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 410 | 480 | 275 | 16 | 95 | 201 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 410 Pipes from Bosega Pipes and Tubes offers a unique and durable look, ideal for a variety of industrial applications. Their pipes are highly resistant to corrosion and oxidation, making them suitable for harsh environments. Bosega’s commitment to standardized manufacturing assures consistent design and performance standards. In addition, their extensive inventory ensures on-time delivery, reducing downtime. The company’s focus on customer satisfaction means tailored solutions for specific needs. With competitive pricing and strong after-sales support, Bosega stands out as a trusted partner in your piping needs. Count on their expertise to improve your work efficiency and reliability.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel 410 Pipes in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

| Designation of Diameter | O/D | Nominal Wall Thickness | ||||||||||||||||||

| DIA | SCH.5S | SCH.5 | SCH 10S | SCH.10 | SCH.20S | SCH.30 | SCH.40S | SCH.40 | SCH 60 | |||||||||||

| (A) | (B) | Meter MM | Wall Thk | Weight Kg/Mtr | Wall Thk | Weight Kg/Mtr | Wall Thk | Weight Kg/Mtr | Wall Thk | Weight Kg/Mtr | Wall Thk | Weight Kg/Mtr | Wall Thk | Weight Kg/Mtr | Wall Thk | Weight Kg/Mtr | Wall Thk | Weight Kg/Mtr | Wall Thk | Weight Kg/Mtr |

| 6 | 1/8 | 10.3 | 1 | 0.23 | 1.2 | 0.27 | 1.5 | 0.33 | 1.73 | 0.37 | ||||||||||

| 8 | 1/4 | 13.7 | 1.2 | 0.37 | 1.65 | 0.49 | 2 | 0.58 | 2.24 | 0.64 | ||||||||||

| 10 | 3/8 | 17.2 | 1.2 | 0.47 | 1.65 | 0.63 | 2 | 0.74 | 2.31 | 0.87 | ||||||||||

| 15 | 1/2 | 21.3 | 1.65 | 0.01 | 1.65 | 0.81 | 2.11 | 1.02 | 2.11 | 1.02 | 2.5 | 1.15 | 2.77 | 1.29 | ||||||

| 20 | 3/4 | 26.7 | 1.65 | 1.03 | 1.65 | 1.03 | 2.11 | 1.3 | 2.11 | 1.3 | 2.5 | 1.49 | 2.87 | 1.71 | ||||||

| 25 | 1 | 33.4 | 1.65 | 1.31 | 1.65 | 1.31 | 2.77 | 2.13 | 2.77 | 2.13 | 3 | 2.24 | 3.38 | 2.54 | ||||||

| 32 | 11/4 | 24.2 | 1.65 | 1.67 | 1.65 | 1.67 | 2.77 | 2.73 | 2.77 | 2.73 | 3 | 2.9 | 3.56 | 3.44 | ||||||

| 40 | 11/2 | 48.3 | 1.65 | 1.93 | 1.65 | 1.93 | 2.77 | 3.16 | 2.77 | 3.16 | 3 | 3.35 | 3.68 | 4.11 | ||||||

| 50 | 2 | 60.3 | 1.65 | 1.93 | 1.65 | 2.42 | 2.77 | 3.99 | 2.77 | 3.99 | 3.5 | 4.9 | 3.91 | 5.52 | ||||||

| 65 | 21/2 | 73 | 2.11 | 3.75 | 2.11 | 3.75 | 3.05 | 5.34 | 3.05 | 5.34 | 3.5 | 6 | 5.16 | 8.77 | ||||||

| 80 | 3 | 88.9 | 2.11 | 4.59 | 2.11 | 4.59 | 3.05 | 6.56 | 3.05 | 6.56 | 4 | 8.37 | 5.49 | 11.47 | ||||||

| 90 | 31/2 | 101.6 | 2.11 | 5.25 | 2.11 | 5.25 | 3.05 | 7.53 | 3.05 | 7.53 | 4 | 9.62 | 5.74 | 13.78 | ||||||

| 100 | 4 | 114.3 | 2.11 | 5.93 | 2.11 | 5.93 | 3.05 | 8.5 | 3.05 | 8.5 | 4.5 | 12.18 | 6.02 | 6.32 | ||||||

| 125 | 5 | 141.3 | 2.77 | 9.61 | 2.77 | 9.61 | 3.4 | 11.74 | 3.43 | 11.74 | 5 | 16.8 | 6.55 | 2210 | ||||||

| 150 | 6 | 168.3 | 2.77 | 11.47 | 2.77 | 11.47 | 3.4 | 14.04 | 3.43 | 14.04 | 5.5 | 22.08 | 7.11 | 28.69 | ||||||

| 200 | 8 | 219.1 | 2.77 | 15 | 2.77 | 15 | 3.76 | 20.77 | 3.76 | 20.27 | 6.35 | 33.82 | 7.04 | 37.38 | 8.18 | 43.2 | 10.81 | 53.9 | ||

| 250 | 10 | 273.1 | 3.4 | 22.95 | 3.4 | 22.95 | 4.19 | 28.2 | 4.19 | 28.2 | 6.35 | 42.41 | 7.8 | 51.81 | 9.27 | 61.22 | 12.2 | 82.8 | ||

| 300 | 12 | 323.9 | 3.96 | 31.72 | 4.19 | 33.6 | 4.57 | 36.54 | 4.57 | 36.54 | 6.35 | 50.48 | 8.38 | 66.2 | 9.53 | 75.01 | 10.31 | 80.94 | 14.27 | 110.62 |

| 350 | 14 | 355.6 | 3.96 | 34.86 | 4.78 | 41.99 | 6.35 | 55.53 | 7.92 | 68.95 | 9.53 | 82.58 | 9.53 | 82.58 | 11.13 | 96 | 15.06 | 128.42 | ||

| 400 | 16 | 406.4 | 4.19 | 42.2 | 4.78 | 48.07 | 6.35 | 63.61 | 7.92 | 79.03 | 9.53 | 94.7 | 9.53 | 94.7 | 12.7 | 125.2 | 16.66 | 162.59 | ||

| 450 | 18 | 457.2 | 4.19 | 47.46 | 4.78 | 54.15 | 6.35 | 71.69 | 7.92 | 89.1 | 11.13 | 124.32 | 9.53 | 106.83 | 14.27 | 158.27 | 19.05 | 209 | ||

| 500 | 2C | 508 | 4.78 | 60.23 | 5.54 | 69.7 | 6.35 | 79.76 | 9.53 | 118.93 | 12.7 | 157.51 | 9.53 | 118.9 | 15.06 | 185.89 | 2062 | 251.65 | ||

| 550 | 22 | 558.8 | 4.78 | 65.95 | 5.54 | 76.75 | 6.35 | 87.84 | 9.53 | 131.07 | 12.7 | 173.66 | 9.53 | 131.07 | 15.88 | 216.04 | 22.23 | 298.55 | ||

| 600 | 24 | 609.6 | 5.54 | 83.8 | 6.35 | 95.92 | 6.35 | 95.92 | 9.53 | 143.2 | 14.27 | 212.72 | 9.53 | 143.2 | 17.45 | 258.74 | 24.59 | 360.21 | ||

| 650 | 26 | 660.4 | 7.92 | 129.4 | 12.7 | 205.97 | 9.53 | 155.32 | ||||||||||||

| 700 | 28 | 711.2 | 7.92 | 139.47 | 12.7 | 222.13 | 15.88 | 276.48 | 9.53 | 167.44 | ||||||||||

| 750 | 3C | 762 | 6.35 | 120.15 | 7.92 | 149.55 | 7.92 | 149.55 | 12.7 | 238.28 | 15.88 | 296.68 | 9.53 | 179.56 | ||||||

| 800 | 32 | 812.8 | 7.92 | 159.62 | 12.7 | 254.44 | 15.88 | 316.88 | 9.53 | 191.69 | 17.48 | 348.11 | ||||||||

| 850 | 34 | 863.6 | 7.92 | 169.64 | 12.7 | 270.5 | 15.88 | 336.96 | 9.53 | 203.74 | 17.48 | 370.22 | ||||||||

| 900 | 36 | 914.4 | 7.92 | 179.77 | 12.7 | 286.75 | 15.88 | 357.28 | 9.53 | 215.93 | 19.05 | 427.09 | ||||||||

| STANDARD | UNS | WERKSTOFF NR. |

| SS 410 | S41000 | 1.4762 |

| NB Sizes | Sch 5 | Sch 10 | Sch 40 | Sch 80 | Sch 160 |

| 1/8″ |  |

|

|

|

|

| 1/4″ |  |

|

|

|

|

| 3/8″ |  |

|

|

|

|

| 1/2″ |  |

|

|

|

|

| 3/4″ |  |

|

|

|

|

| 1″ |  |

|

|

|

|

| 1 1/4″ |  |

|

|

|

|

| 1 1/2″ |  |

|

|

|

|

| 2″ |  |

|

|

|

|

| 2 1/2″ |  |

|

|

|

|

| 3″ |  |

|

|

|

|

| 4″ |  |

|

|

|

|

| 5″ |  |

|

|

|

|

| 6″ |  |

|

|

|

Yes, we offer custom sizes for Stainless Steel 410 Pipes to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

These Stainless Steel 410 Pipes find their place in various sectors, including petrochemical, automotive, and industrial applications where strength and wear resistance are paramount. They’re perfect for use in shafts, valves, pump components, structural supports, and general piping systems that face moderate corrosive conditions. Additionally, they’re utilized in tooling, machinery, and marine applications where hardness, durability, and thermal stability are essential. Their blend of mechanical strength and corrosion resistance guarantees long-lasting performance and reliability across different industrial settings.

©2024 Bosega Pipes and Tubes . All Rights Reserved.