Home > Stainless Steel > Stainless Steel 420 Tubing

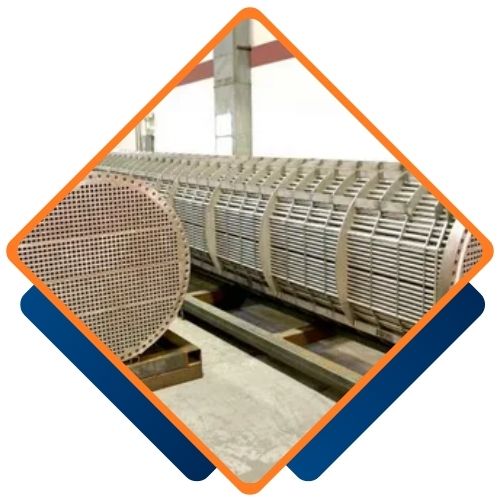

Bosega Pipes and Tubes, located in Cape Town, South Africa, has earned a solid reputation as a reliable manufacturer and supplier of top-notch Stainless Steel 420 Tubing. Renowned for its precision engineering and durability, Bosega provides tubing solutions that align with global industrial standards. The Stainless Steel 420 Tubing is celebrated for its impressive corrosion resistance, high hardness, and exceptional wear resistance, making it a great fit for both structural and mechanical uses. Catering to various industries like automotive, cutlery, chemical processing, and construction, Bosega ensures that their tubing is dependable and long-lasting, promoting efficiency, strength, and safety while adhering to international quality benchmarks for challenging operational settings.

The composition of Bosega’s Stainless Steel 420 Tubing primarily includes iron, chromium (12–14%), along with trace amounts of carbon, manganese, and silicon. This martensitic stainless steel alloy is known for its high hardness and remarkable wear resistance, especially after undergoing heat treatment. In terms of mechanics, it showcases good tensile strength, moderate ductility, and outstanding toughness. These characteristics make it perfect for applications that demand strength, corrosion resistance, and dimensional stability. The unique blend of mechanical durability and chemical makeup guarantees long-lasting performance and reliability, even in moderately corrosive environments, making Stainless Steel 420 Tubing an excellent choice for rigorous industrial and engineering tasks.

Item | Stainless Steel 420 Tube |

Standard | GB, AISI, ASTM, ASME, EN, BS, DIN, JIS |

Type | Seamless / ERW / Welded / Fabricated / CDW |

Outer Diameter Size | SEAMLESS – 1/2″ NB TO 18″ NB WELDED / ERW- 1″ NB TO 16″ NB EFW – 8″ NB TO 110″ NB |

Form | 420 Round Tubing, 420 Square Tubes, 420 Rectangular Tube, “U” Shape 420 Tubing, 420 Hydraulic Tubes |

Wall Thickness | Schedule 10 To Schedule 160 (3 mm to 100 mm Thickness) |

Length | 01 Meter to 12.5 Meters, Single Random Length, Double Random Length And Customize Size End: Plain End, Beveled End, Treaded |

Delivery Conditions | As Rolled, Formed, Stress Relieved, Annealed, Hardened, Tempered, Cold Draw |

Coating | Electropolish, Mechanical Polish, Satin Finish, Passivated |

Testing | Product Analysis, Transverse Tension Test, Flattening Test, Etching Test, Radiographic Examination, Stabilizing Heat Treatment, Intergranular Corrosion Test, Weld Decay Test, Magnetic Particle Detection, Grain Size Test, NACE 0175, Dual Grade, PWHT (POST WELD HEAT TREATMENT), Flare Test, Bend Test, Hardness Test, Tensile Test etc |

Dimension | All Tubes Is Manufactured and Inspected / Tested to the Relevant standards including ASTM and ASME |

Value Added Services | Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Heat Treatment |

Packaging | Loose / Bundle / Wooden Pallet / Wooden Box / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector |

Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |

| Grade | C | Mn | Si | P | S | Cr | |

|---|---|---|---|---|---|---|---|

| 420 | Min. max. | 0.15 – | – 1 | – 1 | – 0.040 | – 0.03 | 12.0 14.0 |

| Tempering Temperature (°C) | Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) | Elongation (% in 50mm) | Hardness Brinell (HB) | Impact Charpy V (J) |

|---|---|---|---|---|---|

| Annealed * | 655 | 345 | 25 | 241 max | – |

| 204 | 1600 | 1360 | 12 | 444 | 20 |

| 316 | 1580 | 1365 | 14 | 444 | 19 |

| 427 | 1620 | 1420 | 10 | 461 | # |

| 538 | 1305 | 1095 | 15 | 375 | # |

| 593 | 1035 | 810 | 18 | 302 | 22 |

| 650 | 895 | 680 | 20 | 262 | 42 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 420 Tubing from Bosega Pipes and Tubes ensures high quality and durability, as these pipes offer excellent corrosion resistance and strength. Our commitment to exceptional service and reliable delivery guarantees customer satisfaction across various industrial applications. Our expertise in stainless steel products ensures you receive a top-tier solution tailored to your needs.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel 420 Tubing in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Yes, we offer custom sizes for Stainless Steel 420 Tubing to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

Bosega’s Stainless Steel 420 Tubing finds extensive use in crafting shafts, fasteners, cutlery, valves, and surgical instruments, thanks to its hardness and wear resistance. In the automotive sector, it’s utilized for parts that face mechanical stress and moderate corrosion. The chemical and petrochemical industries rely on it for equipment that needs to withstand durability and oxidation. Additionally, it’s employed in construction and general engineering projects where strength, dimensional stability, and corrosion resistance are crucial.

©2024 Bosega Pipes and Tubes . All Rights Reserved.