Home > Stainless Steel > Stainless Steel 439 Tubing

Bosega Pipes and Tubes, based in Cape Town, South Africa, stands out as a top-notch manufacturer and supplier of high-quality Stainless Steel 439 Tubing. With a strong focus on precision, durability, and innovation, Bosega delivers reliable tubing solutions that meet global standards. Their Stainless Steel 439 Tubing is crafted for exceptional performance, corrosion resistance, and longevity. It’s a popular choice in the automotive, construction, and industrial sectors, making it perfect for demanding applications. Bosega is committed to excellence, utilizing advanced manufacturing techniques, rigorous quality control, and a customer-centric approach across various industries.

The Stainless Steel 439 Tubing from Bosega is primarily made up of iron, chromium (17–19%), titanium, along with trace amounts of carbon, silicon, and manganese. This ferritic stainless steel alloy is celebrated for its impressive corrosion resistance, particularly in oxidizing and high-temperature settings. On the mechanical side, it boasts moderate tensile strength, good ductility, and remarkable formability. The addition of titanium enhances weldability and minimizes carbide precipitation, boosting durability. These mechanical and chemical traits make Stainless Steel 439 Tubing a fantastic option for applications that require a blend of strength, heat resistance, and long-lasting performance.

| GRADES | TP 439 Stainless Steel Tubes / UNS S43035 / DIN 1.4510 |

| SIZE | 1/2″ NB to 24″ NB |

| STANDARDS | ASTM A213, ASTM A249, ASTM A554, ASTM A269, ASTM A270, ASTM A790, ASTM A789 |

| TYPE | Seamless Tubes, Welded Tubes, EFW Tubes, ERW Tubes, Fabricated Tubes, Cold Drawn Welded Tubes (CDW Tubes) |

| FORM | Round Tubes, Square Tubes, Rectangular Tubes, Oval Tubes, Hydraulic Tube, etc. |

| END | Plain End, Treaded, Beveled End |

| TOLERANCE on Length | Commercial Length: 6000mm +/- 30mm Fix Length: from 1200 mm up to 12000mm with a tolerance up to -0/+ 5mm |

| FINISH | Seamless, Welded, Brushed, Pickled, Solution Annealed and Pickled up to O.D. 219.1mm, Polished Grit 120 – 600, Mirror Polished |

|

Grade |

WERKSTOFF NR. |

UNS |

|

SS 439 |

1.4510 |

S43035 |

|

Grade |

Fe |

Cr |

Si |

Ti |

Mn |

Ni |

Mo |

Nb/Cb |

P |

N |

C |

S |

|

SS 439 |

81.3535 |

17.35 |

0.35 |

0.335 |

0.25 |

0.200 |

0.1 |

0.02 |

0.02 |

0.0100 |

0.01 |

0.0015 |

Tensile strength (annealed) | 438 MPa | 63500 psi |

Yield strength (annealed/ @strain 0.200 %) | 263 MPa | 38100 psi |

Modulus of elasticity | GPa | ksi |

Poisson’s ratio | 0.270 – 0.290 | 0.270 – 0.290 |

Elongation at break (In 2″, 50% cold worked) | 2.80% | 2.80% |

Hardness, Rockwell B (annealed) | 72.9 | 72.9 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel 439 Tubing from Bosega Pipes and Tubes ensures high quality materials that resist corrosion and heat. Their materials offer excellent weldability, low risk of intergranular damage, and durability in tough materials. Bosega offers precision engineered tubing with strict quality control, ensuring reliability in the automotive, industrial and construction industries. Their customer service, competitive pricing and on-time delivery make them a trusted provider of stainless steel specialty solutions.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel 439 Tubing in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

| Wall | Sizes ( O.D.) |

|---|---|

| .010 | 1/16″ , 1/8″ , 3/16″ |

| .020 | 1/16″ , 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ |

| .012 | 1/8″ |

| .016 | 1/8″ , 3/16″ |

| .028 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 3/4″ , 1″ , 1 1/2″ , 2″ |

| .035 | 1/8″ , 3/16″ , 1/4″ , 5/16″ , 3/8″ , 7/16″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .049 | 3/16″ , 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/8″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 2″ , 2 1/4″ |

| .065 | 1/4″ , 5/16″ , 3/8″ , 1/2″ , 16″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 3/4″ , 2″ , 2 1/2″ , 3″ |

| .083 | 1/4″ , 3/8″ , 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 1 5/8″ , 1 7/8″ , 2″ , 2 1/2″ ,3″ |

| .095 | 1/2″ , 5/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .109 | 1/2″ , 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ |

| .120 | 1/2″ , 5/8″ , 3/4″ , 7/8″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 2 1/4″ , 2 1/2″ , 3″ |

| .125 | 3/4″ , 1″ , 1 1/4″ , 1 1/2″ , 2″ , 3″ , 3 1/4″ |

| .134 | 1″ |

| .250 | 3″ |

| .375 | 3 1/2″ |

| Density (lb./ in^2) @ RT | 0.278 | |

|---|---|---|

| Modulus of Elasticity in Tension (psi x 10^6) | 29.0 | |

| Specific Heat (BTU/o F/lb.) | 32 to 212 oF | 0.11 |

| Thermal Conductivity (BTU/hr/ft^2/ft) | 212oF | 168.0 |

| Mean Coefficient of Thermal Expansion (in. x 10^-6 per o F) | 32 to 212oF | 5.6 |

| 32 to 932oF | 6.4 | |

| 32 to 1,472oF | 6.9 | |

| Electrical Resistivity (micro ohms – cm) | at 70oF | 63 |

| Oxidation Resistance – Continuous Service(oF) | 1700 |

Stainless Steel 439 Tube OD | Stainless Steel 439 Tube Tolerance |

|---|---|

4mm to 35mm | +/- 0.08mm |

35mm to 38mm | +/- 0.15mm |

38mm to 60mm | +/- 0.20mm |

60mm and above | +/- 0.25mm |

Yes, we offer custom sizes for Stainless Steel 439 Tubing to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

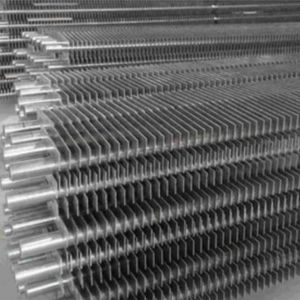

Bosega’s Stainless Steel 439 Tubing finds its way into automotive exhaust systems, heat exchangers, and mechanical equipment that need thermal and corrosion resistance. Its aesthetic appeal and durability make it a great fit for construction and architectural projects. Additionally, this tubing is utilized in the chemical, food processing, and power generation industries due to its oxidation resistance and hygienic qualities. It’s also employed in water heating systems and air preheaters. With its combination of cost-effectiveness, strength, and durability, Stainless Steel 439 Tubing is a dependable choice for modern industrial applications.

©2024 Bosega Pipes and Tubes . All Rights Reserved.