Home > Stainless Steel Tubing > Stainless Steel 446 Tubing

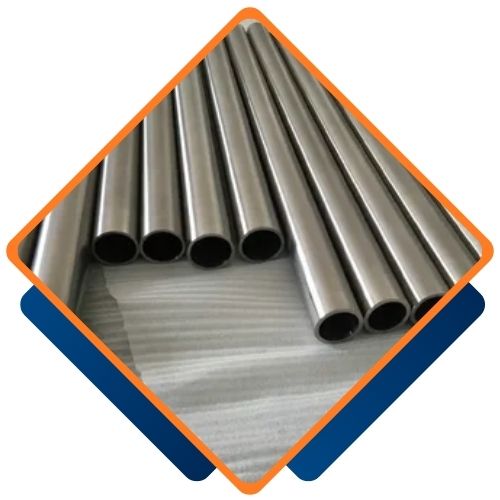

Bosega Pipes and Tubes, located in Cape Town, South Africa, specializes in providing high-performance **Stainless Steel 446 Tubing** designed for applications that require outstanding resistance to high temperatures and oxidation. Grade 446 is a ferritic, heat-resistant stainless steel that’s specifically made for use in elevated-temperature settings. Bosega guarantees that all tubing is manufactured in line with international standards, ensuring precise dimensions, excellent surface quality, and long-lasting reliability for industries that operate under thermally demanding conditions.

Stainless Steel 446 tubing contains high chromium (23-27%) and low carbon, providing excellent oxidation and corrosion resistance at elevated temperatures. Its mechanical properties include a tensile strength of 450 MPa, yield strength of 275 MPa, and elongation of 20%. This alloy resists scaling up to 1100°C and offers good resistance to sulfuric and nitric acids. The advantages of SS 446 tubing include superior durability in extreme environments, high thermal resistance, and excellent performance in corrosive conditions, making it ideal for high-temperature industrial applications.

| Specifications | ASTM A/ASME SA213 / A249 / A269 |

| Dimensions | ASTM, ASME and API |

| SS 446 Tubes Size | 10.29 OD (mm) – 762 OD (mm) |

| Thickness | 0.35 OD (mm) to 6.35 OD (mm) in thickness ranging from 0.1mm to 1.2mm. |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | Seamless / ERW / Welded / Fabricated |

| Form | Round Tubes, Custom Tubes, Square Tubes, Rectangular Tubes, “U” Shape, Hydraulic Tubes |

| Length | Single Random, Double Random & Cut Length. |

| End | Plain End, Beveled End, Treaded |

| Grade | 446 | |

|---|---|---|

| min | max | |

| C | – | 0.20 |

| Mn | – | 1.5 |

| Si | – | 0.75 |

| P | – | 0.040 |

| S | – | 0.030 |

| Cr | 23.0 | 30.0 |

| Mo | – | – |

| Ni | – | 0.50 |

| N | 0.10 | 0.25 |

| Grade | 446 | |

|---|---|---|

| Tensile Strength (MPa) min | 485 | |

| Yield Strength 0.2% Proof (MPa) min | 275 | |

| Elongation (% in 50mm) min | 20 | |

| Hardness | Rockwell B (HR B) max | 92 |

| Brinell (HB) max | 201 | |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

**Stainless Steel 446** (UNS S44600) boasts high chromium content (approximately 23–27%), which gives it remarkable resistance to scaling and oxidation, even at temperatures above 1000°C. This grade also shows good resilience against sulfuric environments and thermal fatigue, making it ideal for heat exchangers, furnaces, and combustion systems. While 446 is a ferritic steel that cannot be hardened through heat treatment and has lower ductility compared to austenitic grades, it excels in performance where many other stainless steels would falter.

Bosega Pipes and Tubes, a leading supplier of Stainless Steel 446 Tubing in Cape Town, South Africa, provides a wide selection of premium pipes and tubes for diverse industrial applications. With a vast inventory and a strong focus on delivering outstanding service, they are the preferred choice for stainless steel products in the region.

You’ll find 446 tubing commonly used in **industrial furnaces**, **kiln components**, **heat treatment equipment**, **exhaust systems**, and **refinery applications**, where it effectively resists scaling, carburization, and oxidation under high thermal stress. It’s also utilized in **boiler tubes**, **incinerator liners**, and **thermal reactors** across industries like petrochemical, power generation, and metallurgy. With its thermal stability and corrosion resistance in tough conditions, Stainless Steel 446 Tubing from Bosega provides a durable and cost-effective solution for extended service in high-temperature environments.

Stainless Steel 446 tubing is widely used in applications requiring high resistance to heat and corrosion. It is ideal for furnace components, heat exchangers, and thermal processing equipment due to its ability to withstand temperatures up to 1100°C. Its excellent resistance to oxidation and sulfuric environments makes it suitable for chemical processing plants, exhaust systems, and incinerators. SS 446 tubing is also used in kiln linings, boiler parts, and flue gas desulfurization systems, where durability and performance in harsh conditions are essential.

©2024 Bosega Pipes and Tubes . All Rights Reserved.