Home > Stainless Steel > Stainless Steel 904L Heat Exchanger Tubing

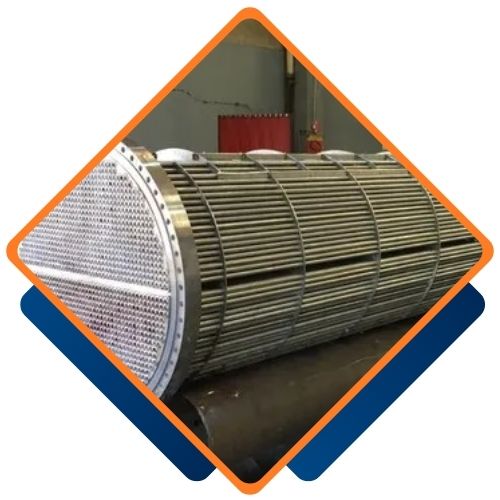

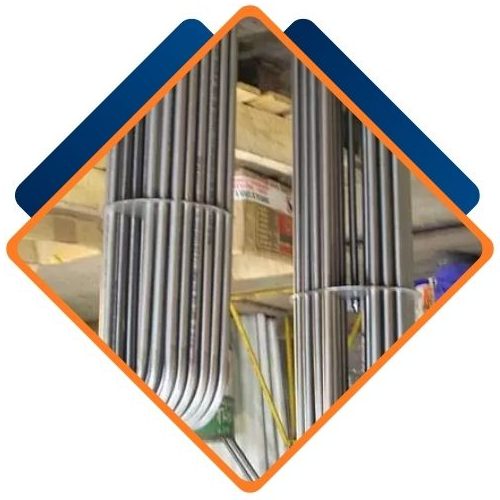

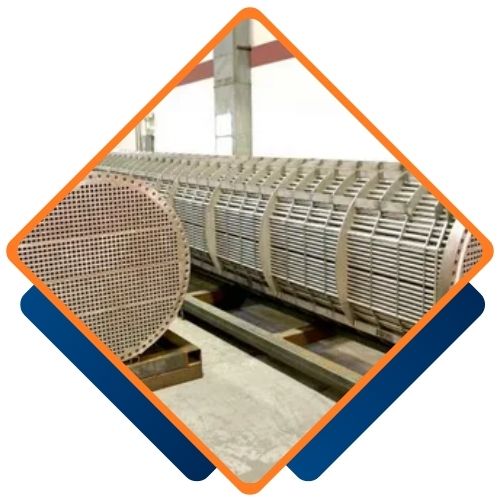

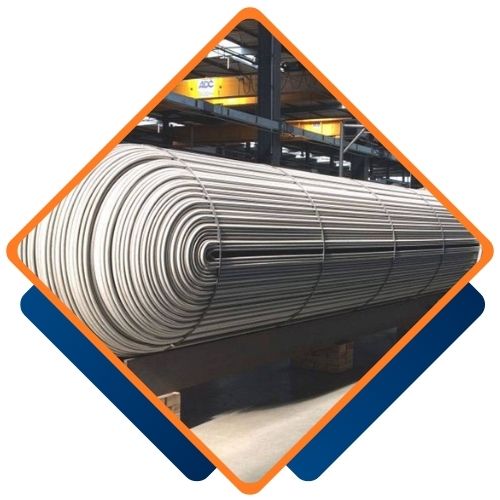

Bosega Pipes and Tubes, located in Cape Town, South Africa, stands out as a reliable supplier of high-performance **Stainless Steel 904L Heat Exchanger Tubing**, specifically designed for challenging and corrosive environments. Renowned for its exceptional corrosion resistance and durability, 904L tubing is the go-to choice for heat exchanger systems across various industries, including chemical processing, power generation, marine applications, and oil refining. Bosega guarantees that each tube adheres to rigorous international standards for dimensional accuracy, surface finish, and pressure resistance, ensuring long-lasting and dependable performance.

Stainless Steel 904L is an austenitic alloy with a composition that includes 20% nickel, 25% chromium, and 4.5% molybdenum, offering exceptional resistance to pitting and crevice corrosion. Its mechanical properties feature a tensile strength of 520 MPa and a yield strength of 220 MPa, ensuring durability under high-stress conditions. The alloy’s low carbon content enhances its weldability and minimizes carbide precipitation. Advantages of 904L heat exchanger tubing include superior resistance to sulfuric acid, high-temperature stability, and excellent formability, making it suitable for demanding applications in chemical processing and oil refining.

Range : 10 mm OD to 50.8 mm OD

Outer Diameter : 6.00 mm to 101.60 mm

Wall Thickness : 0.70 mm to 8.00 mm

Length : up to 20 m (65.62 ft) Length & Customed Required Length

Specifications : ASTM A 213, A 268, A 269, A 789, Equivalent to ASME, EN, JIS Etc.

| Element | SS 904L |

| C | 0.020 max |

| Mn | 2.00 max |

| Si | 1.00 max |

| P | 0.040 max |

| S | 0.030 max |

| Cr | 19.00 – 23.00 |

| Mo | 4.00 – 5.00 max |

| Ni | 23.00 – 28.00 |

| Cu | 1.00 – 2.00 |

| Element | SS 347 | SS 347H |

| Density | 8.0 g/cm3 | 8.0 g/cm3 |

| Melting Point | 1454 °C (2650 °F) | 1454 °C (2650 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 | Psi – 30000 , MPa – 205 |

| Elongation | 35 % | 35 % |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

**Stainless Steel 904L** is a low-carbon, high-alloy austenitic stainless steel enriched with significant amounts of nickel, chromium, molybdenum, and copper. These elements endow it with remarkable resistance to a broad spectrum of corrosive environments, including strong reducing acids like sulfuric and phosphoric acid, as well as protection against chloride-induced pitting and crevice corrosion. The material retains its strength and corrosion resistance even at high temperatures and during continuous thermal cycling, making it particularly effective for heat exchanger and condenser systems. Its excellent weldability and formability facilitate easy fabrication into intricate designs.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel 904L Heat Exchanger Tubing in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

You’ll find 904L heat exchanger tubing widely utilized in **chemical plants**, **desalination facilities**, **petrochemical refineries**, and **marine cooling systems**, where reliability and corrosion resistance are absolutely essential. It’s especially preferred in scenarios dealing with high-chloride or acidic fluids, where standard stainless steels might fail prematurely. These tubes are also commonly found in **air conditioning systems**, **fertilizer production**, and **power plants** that demand a long service life with minimal maintenance.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z6CNDT17‐123 | X1NiCrMoCu25-20-5 |

Stainless Steel 904L Heat Exchanger Tubing is widely used in various industries due to its excellent corrosion resistance and durability. It is ideal for applications in chemical processing, oil and gas, and marine environments, where exposure to aggressive media is common. The tubing is also employed in power plants and desalination plants, ensuring efficient heat transfer and enhanced performance. Additionally, its ability to withstand high temperatures and pressures makes it suitable for heat exchangers in petrochemical facilities, contributing to reliable operations in challenging conditions.

©2024 Bosega Pipes and Tubes . All Rights Reserved.