Home > Stainless Steel > Stainless Steel Electropolished Pipes

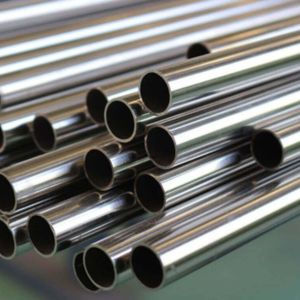

Bosega Pipes and Tubes, based in Cape Town, South Africa, stands out as a reliable supplier of top-notch **Stainless Steel Electropolished Pipes** tailored for high-purity and hygienic applications. These pipes go through a sophisticated electropolishing process that not only enhances their surface smoothness but also eliminates contaminants and boosts corrosion resistance. Bosega guarantees that all electropolished pipes comply with stringent international standards for surface finish, cleanliness, and dimensional accuracy, making them a perfect fit for critical sectors like pharmaceuticals, food processing, biotechnology, and semiconductor manufacturing.

Stainless Steel Electropolished Pipes are typically made from grades like 304 or 316, containing iron, chromium (18-20%), nickel (8-10%), and molybdenum (2-3% for 316). Electropolishing enhances corrosion resistance, smoothness, and cleanliness, producing superior surface quality. Mechanical properties include high tensile strength (up to 580 MPa), good ductility, and excellent weldability. Advantages include resistance to pitting and crevice corrosion, reduced surface roughness for easier cleaning, improved aesthetics, and longer service life in harsh environments, making them ideal for pharmaceutical, food, and chemical industries.

| Standard Specification | ASTM A312 / ASTM SA312 |

| ANSI Specification | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| Available Shapes and Types | Square, Round, Rectangle, Hex, Hydraulic, Honed |

| Manufacturing Type | Fabricated, Welded, CDW, Seamless, 100% X Ray Welded, ERW |

| Pipe End Abbreviations | Treaded On End, Beveled One End, Treaded Both Ends, Bevel small end, Bevel large end, Beveled end, Plain Both Ends, Bevel one end, Plain One End, Bevel both ends |

| Various Technical Delivery Conditions Types | Annealed and Pickled, Cold Drawn, Polished, Bright Annealed |

| Different Surface Finish | 2B, No.4, No.1, No.8 Mirror Finish or custom Finish as per customer Requirements |

| Electropolished Pipes Schedule | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| We also provide | Cutting, Customer Tagging/ Marking, Beveling, Threading, Material testing, Grooving, Color Coding, Threading, Export Packaging, Polishing, Non Export Documentation, MTR’s Available, Machining, Destructive, Ultrasonic Testing, Destructive |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Typically crafted from stainless steel grades such as 304, 316, or 316L, **Stainless Steel Electropolished Pipes** undergo an electropolishing process that removes a thin layer from both the inner and outer surfaces. This results in a bright, ultra-smooth, and passivated finish that significantly reduces the risk of bacterial adhesion, enhances cleanability, and minimizes product contamination in sensitive applications. Additionally, these pipes offer improved corrosion resistance, especially in harsh or sterile environments, and come in various sizes and wall thicknesses to cater to specific system needs.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel Electropolished Pipes in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

Thanks to their outstanding surface quality and hygienic features, electropolished pipes find extensive use in **pharmaceutical processing lines**, **cleanroom environments**, **food and beverage systems**, and **high-purity water systems**. They are also crucial in **biotechnology**, **dairy**, and **cosmetic production**, where cleanliness, sterility, and corrosion resistance are essential. The smooth internal surface of the pipe promotes efficient fluid flow, reduces pressure drop, and enhances the effectiveness of cleaning procedures like CIP (Clean-In-Place) and SIP (Steam-In-Place).

Stainless steel electropolished pipes are widely used in industries requiring high hygiene standards and corrosion resistance. Common applications include pharmaceuticals, food and beverage processing, and biotechnology, where cleanliness is critical. These pipes facilitate smooth fluid flow, reducing contamination and residue buildup. In chemical processing, they withstand harsh environments and aggressive substances. Electropolishing enhances surface smoothness, improving resistance to pitting and corrosion. Additionally, they are utilized in HVAC systems, water treatment facilities, and semiconductor manufacturing, ensuring durability and reliability in various demanding applications.

©2024 Bosega Pipes and Tubes . All Rights Reserved.