Home > Stainless Steel > Stainless Steel ERW Pipes

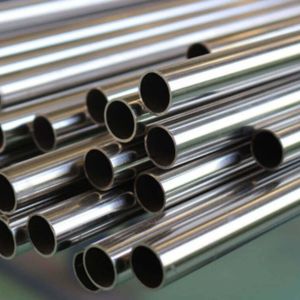

Bosega Pipes and Tubes, located in Cape Town, South Africa, stands out as a trusted manufacturer and supplier of top-notch **Stainless Steel ERW (Electric Resistance Welded) Pipes**. These pipes are produced using cutting-edge welding techniques that guarantee consistent quality, uniformity, and precise dimensions. Renowned for their smooth finish and cost-effectiveness, Bosega’s ERW pipes are perfect for a variety of applications, including construction, infrastructure, water supply systems, and general industrial use. The company follows international standards, delivering reliable and durable piping solutions to clients across diverse sectors.

Stainless Steel ERW (Electric Resistance Welded) pipes are made primarily from austenitic stainless steel grades, commonly 304 and 316. These pipes offer excellent mechanical properties, including high tensile strength (up to 550 MPa), yield strength (up to 250 MPa), and good elongation (up to 40%). Advantages include superior corrosion resistance, durability, and low maintenance. Their smooth surface enhances flow characteristics, making them ideal for various applications, including plumbing, food processing, and chemical industries, while their weldability allows for efficient fabrication.

| Standard Specification | ASTM A312, A270, A249, A269, A268, A358, A213 |

| ANSI / ASME Specification | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| Shapes and Types we produce | Hex, Hydraulic, Square, Round, Honed, Rectangle |

| Manufacturing Type | Fabricated, 100% X Ray Welded, ERW (Electric Resistance Welded), CDW, Welded |

| Pipe End Forming | Plain One End, Beveled One End, Bevel large end, Bevel one end, Bevel both ends, Beveled end, Bevel small end, Plain Both Ends, Treaded Both Ends, Treaded On End |

| Various TDC Types | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Material Surface Finish | 2B, No.4, No.1, No.8 Mirror Finish or custom Finish as per customer Requirements |

| ASME B36.10 Pipe Schedules | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Available Value Added Services | Color Coding, Cutting, Threading, Grooving, Export Documentation, MTR’s Available, Polishing, Material testing, Beveling, Destructive, Threading, Export Packaging, Destructive, Machining, Non Customer Tagging/ Marking, Ultrasonic Testing |

| Marking |

|

| Grades |

|

| Grade | Elastic Modulus (GPa) | Electrical Resistivity (nΩ.m) | Mean Coefficient of Thermal Expansion (μm/m/°C) | Density (kg/m3) | Specific Heat 0-100°C (J/kg.K) | Thermal Conductivity (W/m.K) | |||

|---|---|---|---|---|---|---|---|---|---|

| 0-100°C | 0-315°C | 0-538°C | at 100°C | at 500°C | |||||

| SS ERW Pipe | 193 | 720 | 17.2 | 17.8 | 18.4 | 8000 | 500 | 16.2 | 21.5 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel ERW Pipes from Bosega Pipes and Tubes ensures high-quality, corrosion-resistant pipes with excellent durability and strength. We provide reliable performance in demanding environments, and our electric resistance Welded (ERW) process guarantees superior precision and consistency in manufacturing.

**Stainless Steel ERW Pipes** are generally crafted from grades like 304, 316, and 316L, which provide outstanding corrosion resistance, solid mechanical properties, and a clean internal surface. The ERW process shapes stainless steel strips into round forms and welds the seam using electric resistance, eliminating the need for filler material. This method results in pipes that are strong, lightweight, and well-suited for low to medium pressure applications. The welded seam undergoes heat treatment and testing to ensure it meets both structural integrity and safety standards.

| Nominal size in Inch | Wall thickness in Inch | Outside diameter in mm | Wall thickness in mm | Outside diameter in Inch | Weight [Kg/M] | Weight [lb/ft] |

|---|---|---|---|---|---|---|

| 1/2 Inch | 0.065 | 21.3 mm | 1.65 | 0.840 | 0.80 | 0.54 |

| 3/4 Inch | 0.065 | 26.7 mm | 1.65 | 1.050 | 1.03 | 0.69 |

| 1 Inch | 0.065 | 33.4 mm | 1.65 | 1.315 | 1.30 | 0.87 |

| 1 1/4 Inch | 0.065 | 42.2 mm | 1.65 | 1.660 | 1.66 | 1.12 |

| 1 1/2 Inch | 0.065 | 48.3 mm | 1.65 | 1.900 | 1.91 | 1.28 |

| 2 Inch | 0.065 | 60.3 mm | 1.65 | 2.375 | 2.40 | 1.61 |

| 2 1/2 Inch | 0.083 | 73.0 mm | 2.11 | 2.875 | 3.71 | 2.49 |

| 3 Inch | 0.083 | 88.9 mm | 2.11 | 3.500 | 4.54 | 3.05 |

| 3 1/2 Inch | 0.083 | 101.6 mm | 2.11 | 4.000 | 5.21 | 3.50 |

| 4 Inch | 0.083 | 114.3 mm | 2.11 | 4.500 | 5.88 | 3.95 |

| 5 Inch | 0.109 | 141.3 mm | 2.77 | 5.563 | 9.52 | 6.40 |

| 6 Inch | 0.109 | 168.3 mm | 2.77 | 6.625 | 11.38 | 7.65 |

| 8 Inch | 0.109 | 219.1 mm | 2.77 | 8.625 | 14.87 | 9.99 |

| 10 Inch | 0.134 | 273.1 mm | 3.4 | 10.750 | 22.76 | 15.29 |

| 12 Inch | 0.156 | 323.9 mm | 3.96 | 12.750 | 31.44 | 21.13 |

| 14 Inch | 0.156 | 355.6 mm | 3.96 | 14.000 | 34.56 | 23.22 |

| 16 Inch | 0.165 | 406.4 mm | 4.19 | 16.000 | 41.83 | 28.11 |

| 18 Inch | 0.165 | 457.0 mm | 4.19 | 18.000 | 47.09 | 31.64 |

| 20 Inch | 0.188 | 508.0 mm | 4.78 | 20.000 | 59.70 | 40.12 |

| 22 Inch | 0.188 | 559.0 mm | 4.78 | 22.000 | 65.75 | 44.18 |

| 24 Inch | 0.218 | 610.0 mm | 5.54 | 24.000 | 83.11 | 55.85 |

| 30 Inch | 0.250 | 762.0 mm | 6.35 | 30.000 | 119.09 | 80.02 |

These pipes find extensive use in **water pipelines**, **architectural applications**, **automotive exhaust systems**, and **industrial structural support** due to their strength and aesthetic appeal. In sectors like **food processing**, **pharmaceuticals**, and **chemicals**, they are favored for their hygienic properties and resistance to corrosion. ERW pipes are also a go-to choice in **firefighting systems**, **HVAC**, and **agricultural irrigation**, where balancing performance and cost is essential. With their straightforward installation and long-lasting durability, Stainless Steel ERW Pipes provide a versatile and reliable solution for a wide range of engineering needs.

Stainless Steel ERW (Electric Resistance Welded) pipes are widely used in various industries due to their excellent corrosion resistance and strength. Common applications include oil and gas transportation, chemical processing, water supply systems, and food and beverage industries. They are also utilized in construction for structural support and plumbing. Their durability makes them suitable for marine applications, automotive components, and HVAC systems. Overall, stainless steel ERW pipes offer versatility and reliability in demanding environments.

©2024 Bosega Pipes and Tubes . All Rights Reserved.