Home > Stainless Steel > Stainless Steel Heat Exchanger Tubing

Bosega Pipes and Tubes is a reputable manufacturer and supplier located in Cape Town, South Africa, specializing in top-notch Super Duplex Steel Tubing. Known for providing high-performance piping solutions, Bosega caters to a wide range of industries with products that are celebrated for their durability, corrosion resistance, and strength. With a strong focus on quality and customer satisfaction, Bosega Pipes and Tubes offers tailored Super Duplex Steel Tubing that complies with both international and local industry standards. Thanks to their advanced manufacturing techniques and strict quality control measures, they have become a go-to partner for critical applications in tough and demanding environments.

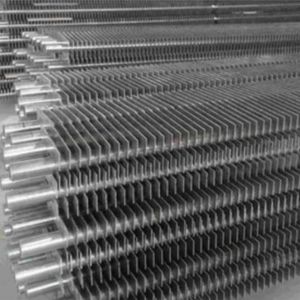

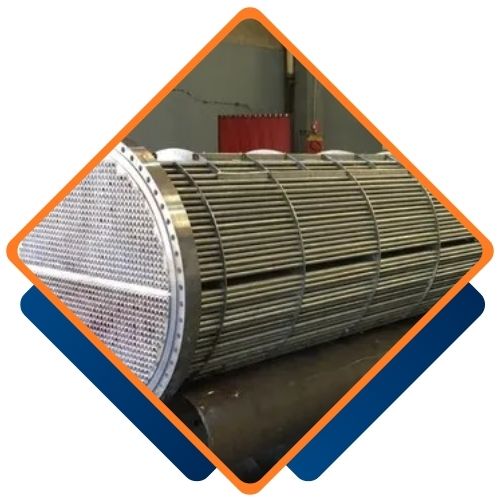

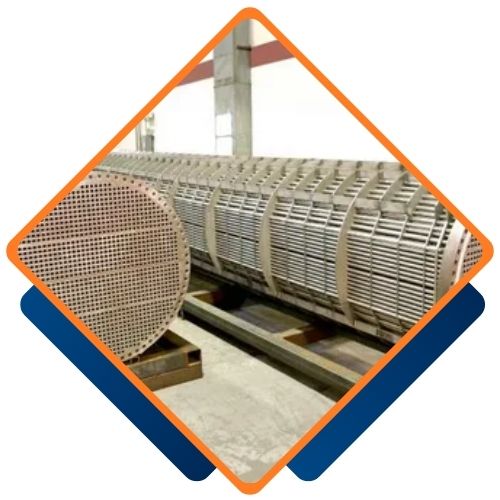

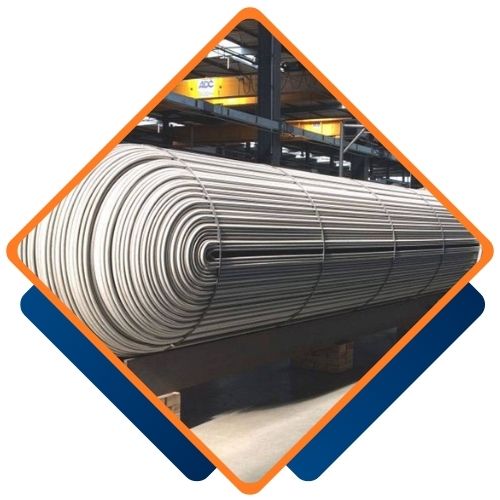

The stainless steel heat exchanger tube is composed mainly of iron, chromium (10-30%) and nickel, which is usually supplemented with molybdenum for increased corrosion resistance. Its mechanical properties include high tensile strength (up to 750 MPa) and yield strength (205-310 MPa) to ensure tubing durability under pressure. The smooth surface provides excellent heat transfer and reduces fouling. Benefits include exceptional corrosion and heat resistance, making it ideal for harsh environments. Stainless steel heat exchangers are widely used in the chemical industry, oil and gas, and HVSC for reliable and efficient thermal applications.

| Marking | All Stainless Steel Heat Exchanger tubes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

|---|---|

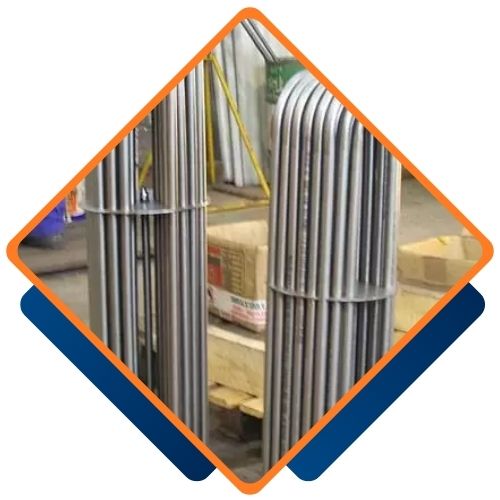

| Stainless Steel Heat Exchanger Tube Size | 3.35 mm OD To 101.6 mm OD |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| SS tube Length | Single Random, Double Random, Standard & Cut length |

| Stainless Steel Heat Exchanger Tube Type | Seamless, ERW, EFW, Welded, Fabricated |

| Stainless Steel Heat Exchanger Tube Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

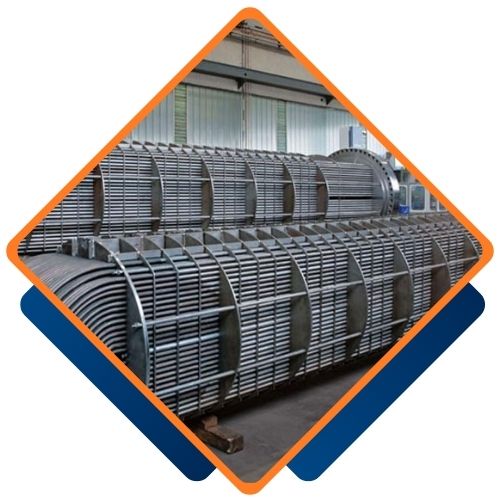

| Stainless Steel tube Form | Round, Coil, Square, Rectangular, Boiler, Hydraulic, Straight or ‘U’ bent Tubes, Hollow, LSAW Tubes Etc. |

| Stainless Steel Welded Tube Size | 6.35 mm OD To 152 mm OD |

| End | Plain End, Beveled End, Treaded |

| Specialize in | Stainless Steel Capillary Tube & Other Odd Size Stainless Steel Heat Exchanger & Condenser Tubes |

| Application | Oil Tube, Gas Tube, Fluid Tube, Boiler and Heatexchanger |

| Stainless Steel Tube Standards | ASTM B/ASME SB674 / SB677 |

| Test Certificate | Manufacturer Test Certificate Laboratory Test Certificate from Govt. Approved Lab. Under Third Party Inspection |

| Stainless Steel Heat Exchanger tubing wall thickness | 0.020″ –0.220″, (special wall thicknesses available) |

| Material | C | Mn | Si | P | S | Cr | MO | Ni | Cu | |

| SS | min. | – | – | – | – | – | 19.0 | 4.0-5.0 | 23.0 | 1.0 |

| max. | 0.20 | 2.0 | 1.0 | 0.045 | 0.035 | 23.0 | 28.0 | 2.0 | ||

| Material | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| SS | 490 | 220 | 35 | 70-90 typical | – |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Choosing Stainless Steel Heat Exchanger Tubing from Bosega Pipes and Tubes ensures high quality and durability, as these pipes offer excellent corrosion resistance and strength. Our commitment to exceptional service and reliable delivery guarantees customer satisfaction across various industrial applications. Our expertise in stainless steel products ensures you receive a top-tier solution tailored to your needs.

Super Duplex Steel Tubing is mainly made up of about 25% chromium, 7% nickel, 4% molybdenum, along with trace amounts of nitrogen and manganese, resulting in a well-balanced austenitic-ferritic microstructure. This dual-phase design grants it impressive strength and outstanding resistance to stress corrosion cracking, pitting, and crevice corrosion. Its mechanical properties boast a high tensile strength of around 750 MPa and a yield strength of about 550 MPa, with elongation values typically exceeding 25%. The tubing also shows good weldability and toughness, even in sub-zero temperatures, making it perfect for challenging operational settings.

Yes, we offer custom sizes for Stainless Steel Heat Exchanger Tubing to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

Bosega Pipes and Tubes’ Super Duplex Steel Tubing is widely utilized across various high-demand sectors due to its remarkable corrosion resistance and mechanical strength. It’s commonly found in offshore oil and gas platforms, desalination plants, chemical processing industries, and marine environments where resistance to chloride-induced corrosion is crucial. Power generation plants, structural applications, heat exchangers, and pressure vessels also reap the benefits of its durability and performance under extreme conditions. The tubing’s versatility, long service life, and low maintenance needs make it a smart choice for modern infrastructure and essential engineering systems.

©2024 Bosega Pipes and Tubes . All Rights Reserved.