Home > Stainless Steel > Stainless Steel Seamless Pipes

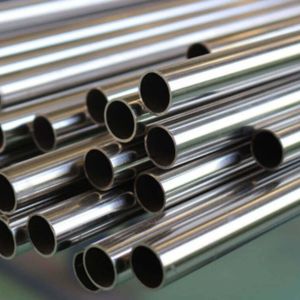

Bosega Pipes and Tubes, located in Cape Town, South Africa, stands out as a reliable manufacturer and supplier of top-notch **Stainless Steel Seamless Pipes**. Renowned for their precision engineering and exceptional durability, these pipes are crafted without any welding seams, which guarantees superior strength and impressive resistance to pressure. Bosega’s seamless pipes adhere to strict international standards and are built to perform consistently in challenging industrial settings. They cater to various sectors, including oil and gas, chemical processing, power generation, and food industries, offering tailored solutions to meet specific operational needs.

Stainless steel seamless pipes typically consist of iron, chromium (10.5% or more), nickel, and other alloying elements like molybdenum. They exhibit excellent mechanical properties, including high tensile strength (up to 550 MPa), good ductility, and resistance to corrosion and oxidation. Their advantages include seamless construction for reduced risk of leakage, high pressure and temperature resistance, lightweight design, and versatility in various applications like oil and gas, pharmaceuticals, and food processing. Additionally, they provide aesthetic appeal and hygienic properties, making them ideal for critical industries.

| Standard Specification | ASTM A 312/ ASME SA 312/ EN10216-5 |

| Size | ½” to 6” NB Sch 10s, 40s, & 80s, 160s |

| Wall Thickness | 0.1 – 60 mm |

| Length |

|

| Specialized in | Large Diameter Size Stainless Steel Pipe Supplier in India |

| Surface Finish | Bright, Cold Finish, Annealing, Polished, Pickling |

| Standard | JIS, GB, ASME, AISI, ASTM, AMS, EN, DIN, GOST |

| Types | Seamless, ERW, Welded, EFW Supplier and Manufacturer |

| Manufacturing Shapes | Round, Rectangle, Square, Box Section |

| Manufacturing Technology | Hot / Cold Formed |

| Inspection, Test Reports | Mill Test Certificates, EN 10204 3.1, PMI Test Reports, Mechanical Reports, Chemical Reports, NABL Approved Lab Reports, Visual Inspection Reports, Third Party Inspection, Destructive and Non Destructive Test Reports |

| Technique | Cold Rolled Hot Rolled |

| Schedule Pipe Thickness Range | SCH160, XS, SCH120, XXS, STD, SCH140, SCH40, SCH20, SCH60, SCH80, SCH30, SCH80, Supplier in Mumbai |

| Marking | All Pipes are marked as follows: Supplier or Manufacturer’s Name, OD, Length, Standard, Grade, Thickness, Heat No. |

| Value Added Services provided by Suppliers | Threading, Destructive, Beveling, Non Destructive, Cutting, Ultrasonic Testing, Polishing |

ANSI B36.10 / ANSI B36.19

| Size Range | Schedule Chart | Manufacturing Types |

|---|---|---|

| O. D. .5”-8” Available Length: 17’ – 24’ | SCH 5 | Seamless, Welded |

| O. D. : 0.5″ thru 20″ Available Length: 17′ – 24′ | SCH 10 | Seamless, Welded |

| O. D. : 0.25″ thru 20″ Available Length: 17′ – 24′ | SCH 40 | Seamless, Welded |

| O. D. : 0.5″ thru 20″ Available Length: 17′ – 24′ | SCH 80 | Seamless, Welded |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Typically made from grades like 304, 316, and 316L stainless steel, **Stainless Steel Seamless Pipes** boast excellent corrosion resistance, high tensile strength, and good ductility. The lack of welds minimizes the risk of leaks and failures, especially under high-pressure or high-temperature conditions. These pipes maintain their integrity even in extreme environments, providing resistance to oxidation, scaling, and a range of chemicals. Their smooth internal surface promotes efficient fluid flow, making them ideal for critical applications that demand cleanliness and reliability.

Bosega Pipes and Tubes, one of the largest suppliers of Stainless Steel Seamless Pipes in Cape Town, South Africa, offers a comprehensive range of high-quality pipes and tubes suitable for various industrial applications. Their extensive inventory and commitment to exceptional service make them a go-to choice for stainless steel products in the region.

These pipes are extensively utilized in industries that require high-performance materials capable of enduring harsh conditions. They are commonly found in **petrochemical plants**, **offshore drilling rigs**, **power plants**, and **pharmaceutical manufacturing**, where contamination-free, corrosion-resistant piping is crucial. Additionally, stainless steel seamless pipes are favored in **food processing** and **water treatment** facilities due to their hygienic properties. Their sturdy construction, combined with outstanding mechanical and chemical resistance, makes them a go-to choice for long-term industrial applications.

Stainless steel seamless pipes are widely used in various industries due to their excellent corrosion resistance, strength, and durability. They are commonly employed in oil and gas, chemical processing, and power generation to transport fluids and gases. Additionally, these pipes are utilized in construction for structural applications and in the food and beverage industries for hygienic processing. Their high temperature and pressure resistance make them ideal for applications in marine environments and the automotive and pharmaceutical sectors, ensuring reliable performance across diverse settings.

©2024 Bosega Pipes and Tubes . All Rights Reserved.