Home > Stainless Steel > Stainless Steel Welded Tubing

Bosega Pipes & Tubes is a renowned stainless steel welded tubing manufacturer based in the Cape Towns, South Africa. Known for their commitment to quality and innovation we offer a comprehensive range of welded tubing solutions for a variety of applications across industries. Our products are made from high quality stainless steel, ensuring exceptional strength, durability and resistant to corrosion. With a focus on customer satisfaction we deliver reliable service and on-time delivery efficiently meeting the needs of its customers.

Bosega Pipes and Tubes, based in Cape Town, South Africa, stands out as a reliable manufacturer and supplier of top-notch stainless steel welded tubing, catering to a variety of industrial needs. With a strong focus on quality and precision, Bosega ensures that their welded tubing adheres to international standards for strength, durability, and resistance to corrosion. Thanks to their cutting-edge production techniques and rigorous quality checks, customers can count on consistent performance and accurate dimensions. They serve a diverse range of industries, including construction, food processing, pharmaceuticals, automotive, and energy, providing tailored tubing solutions that meet the unique requirements of each project and client.

| Marking | All Stainless Steel Welded tubes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

|---|---|

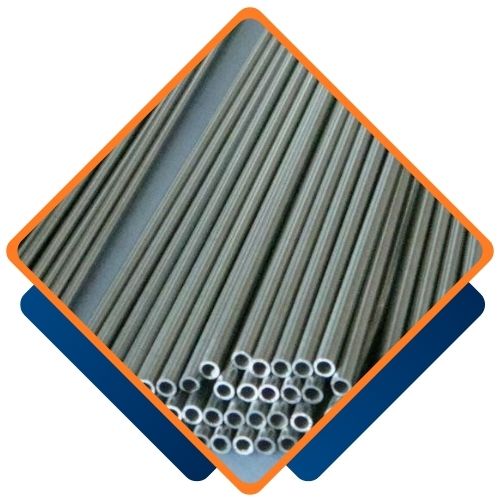

| Stainless Steel Welded Tube Size | 3.35 mm OD To 101.6 mm OD |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| SS tube Length | Single Random, Double Random, Standard & Cut length |

| Stainless Steel Tube Type | Seamless, ERW, EFW, Welded, Fabricated |

| Stainless Steel Tube Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

| Stainless Steel tube Form | Round, Coil, Square, Rectangular, Boiler, Hydraulic, Straight or ‘U’ bent Tubes, Hollow, LSAW Tubes Etc. |

| Stainless Steel Welded Tube Size | 6.35 mm OD To 152 mm OD |

| End | Plain End, Beveled End, Treaded |

| Specialize in | Stainless Steel Welded Capillary Tube & Other Odd Size Stainless Steel Welded Heat Exchanger & Condenser Tubes |

| Application | Oil Tube, Gas Tube, Fluid Tube, Boiler and Heat exchanger |

| Stainless Steel Welded Tube Standards | ASTM B/ASME SB674 / SB677 |

| Test Certificate | Manufacturer Test Certificate Laboratory Test Certificate from Govt. Approved Lab. Under Third Party Inspection |

| Stainless Steel Welded tubing wall thickness | 0.020″ –0.220″, (special wall thicknesses available) |

| Material | C | Mn | Si | P | S | Cr | MO | Ni | Cu | |

| SS | min. | – | – | – | – | – | 19.0 | 4.0-5.0 | 23.0 | 1.0 |

| max. | 0.20 | 2.0 | 1.0 | 0.045 | 0.035 | 23.0 | 28.0 | 2.0 | ||

| Material | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| SS | 490 | 220 | 35 | 70-90 typical | – |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

The process of creating stainless steel welded tubing involves shaping stainless steel strips into a cylindrical form and then expertly welding the seam using advanced methods like TIG (Tungsten Inert Gas) welding. Common grades such as 304, 304L, 316, and 316L are known for their impressive corrosion resistance, strength, and formability. While the mechanical properties can vary based on the grade and thickness, they generally offer good tensile strength, durability, and the ability to withstand high temperatures and pressure. The smooth inner surface of welded tubing makes it ideal for fluid transfer and sanitary applications, while its consistent wall thickness and finish facilitate easy fabrication and a long lifespan.

Stainless steel welded tubing finds its place in a multitude of industries thanks to its versatility, hygiene, and resistance to corrosion. You’ll often see it in heat exchangers, food and beverage processing systems, pharmaceutical equipment, architectural structures, automotive exhaust systems, and water treatment facilities. Its resilience against harsh cleaning agents and tough environments makes it perfect for sanitary and cleanroom applications. Additionally, the

Yes, we offer custom sizes for Stainless Steel Welded Tubing to meet your specific requirements. Our team at Bosega Pipes and Tubes is committed to providing tailored solutions for all your Piping & tubing needs. For more details, contact us at sales@bosegapipes.co.za.

Stainless steel welded tubing is widely used in various industries due to its strength and versatility. It acts as a building support and signature in the construction industry providing long-lasting safety and strength. The automotive industry uses welded tubing for exhaust and fuel lines to ensure maximum efficiency. In a pharmaceutical manufacturing environment it is important for water and air transport due to its excellent corrosion resistance. Furthermore in food and beverage manufacturing for sanitary use as well as in HVAC.

©2024 Bosega Pipes and Tubes . All Rights Reserved.